Hollow slab beam reinforcing method and hollow slab beam

A hollow slab girder and hollow slab technology, used in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of insufficient shear bearing capacity, difficulty in dismantling and rebuilding, and high cost, so as to reduce maintenance and reinforcement costs and prevent self-weight from increasing. Excessive, saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The invention provides a hollow slab girder strengthening method, which converts the cavity section of the hollow slab girder into a solid section, and adds reinforcement materials from the cavity, thereby improving the shear bearing capacity of the hollow slab girder. The hollow slab girder strengthening method, It is suitable for strengthening ordinary (or prestressed) concrete hollow slab beams with insufficient shear bearing capacity.

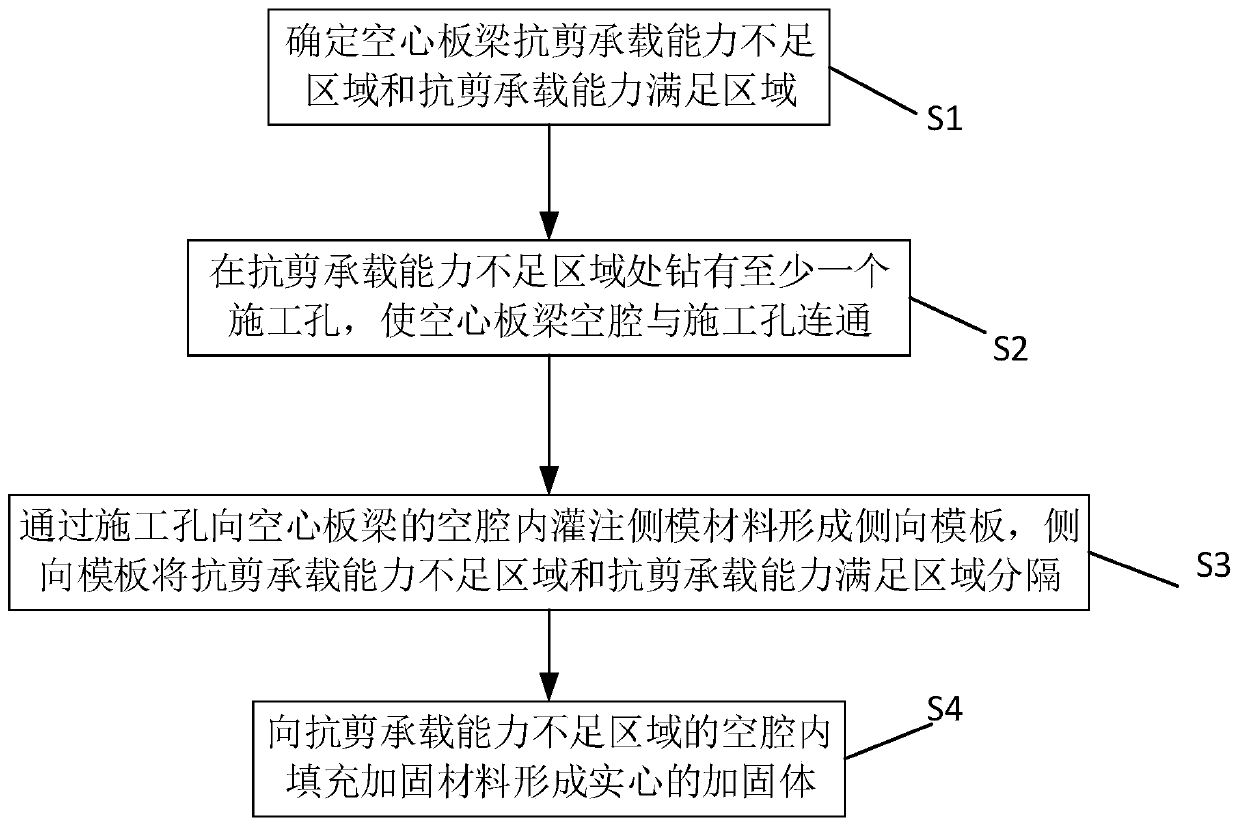

[0053] figure 1 It is a flow chart of the method for strengthening hollow slab beams provided by the present invention, such as figure 1 As shown, the method includes the following steps:

[0054] S1: Determine the area where the shear capacity of the hollow slab beam is insufficient and the area where the shear capacity is sufficient.

[0055] According to the bridge structure, design vehicle load and other parameters, the area with insufficient shear bearing capacity and the area with sufficient shear bearing capacity of the holl...

Embodiment 2

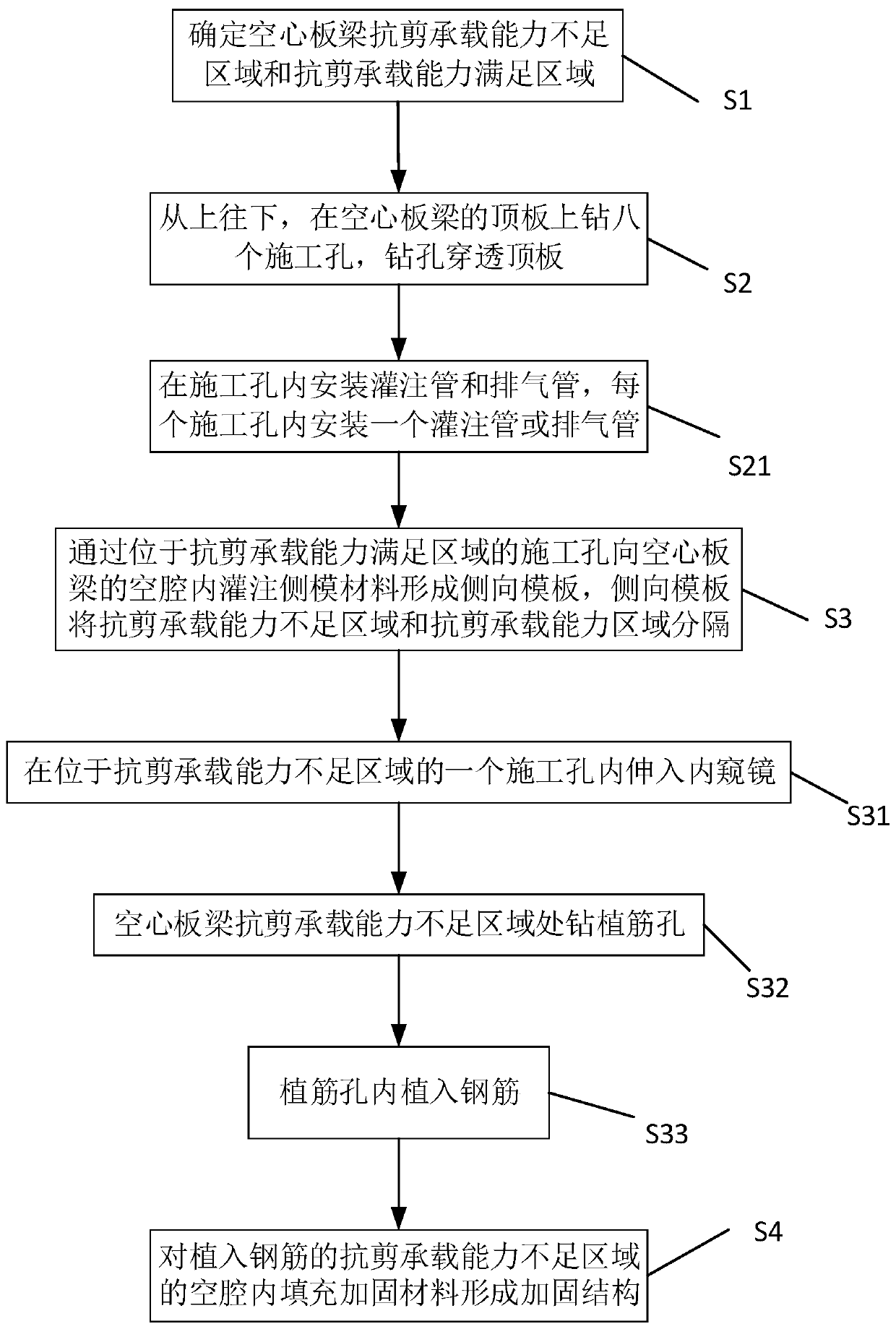

[0065] figure 2 It is a flow chart of the hollow slab beam strengthening method provided by the embodiment of the present invention, such as figure 2 As shown, this embodiment provides a method for strengthening hollow slab girders, which is mainly for the reinforcement of hollow slab girders that have been in service in bridges.

[0066] Compared with the first embodiment, the main steps of the method for strengthening the hollow slab girder in this embodiment are the same as those in the first embodiment, and only further specific limitations are made to step S2 in the first embodiment. This embodiment is mainly aimed at the specific description of the method for strengthening the hollow slab girder under the condition that the traffic on the bridge deck may be interrupted.

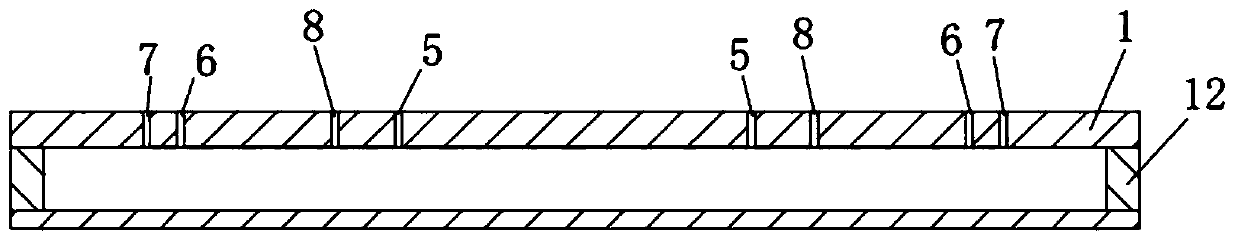

[0067] image 3 It is a schematic diagram of the structure after the construction hole is drilled for the hollow slab beam in this embodiment, Figure 4 It is a structural schematic diagram of the ...

Embodiment 3

[0090] Figure 8 It is a flow chart of the hollow slab beam strengthening method provided by the embodiment of the present invention, such as Figure 8 As shown, this embodiment provides a method for strengthening hollow slab girders, which is mainly for the reinforcement of hollow slab girders that have been in service in bridges.

[0091] Compared with the second embodiment, the main steps of the method for strengthening the hollow slab girder in this embodiment are the same as those in the second embodiment, and only further specific limitations are made to step S2 in the first embodiment. This embodiment is mainly aimed at the specific description of the method for strengthening the hollow slab girder under the condition that the traffic on the bridge deck cannot be interrupted.

[0092] Figure 9 It is a schematic diagram of the structure after the construction hole is drilled for the hollow slab beam in this embodiment, Figure 10 It is a structural schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com