Test tube sending work station with storage mechanism

A workstation and test tube technology, used in conveyors, transportation and packaging, etc., can solve the problems of high error rate, blood damage, long system waiting time, etc., and achieve the effect of fast transmission speed and perfect reception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the embodiments of the present invention and the technical solutions of the existing equipment more clearly, a clear and complete description of the technical solutions in the specific embodiments of the present invention will be expounded in conjunction with the accompanying drawings, which is beneficial to the understanding of the technology.

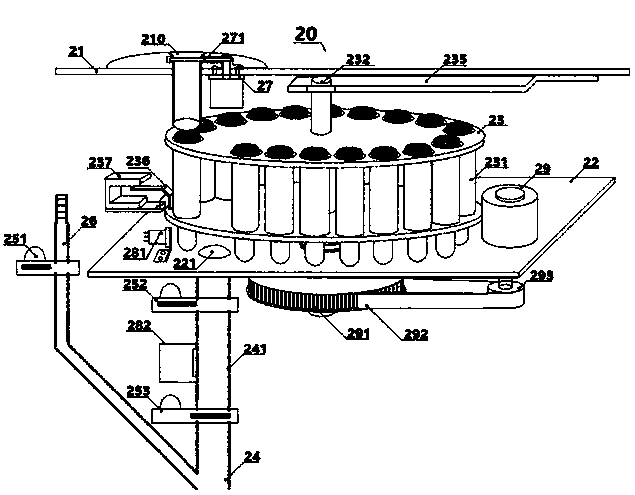

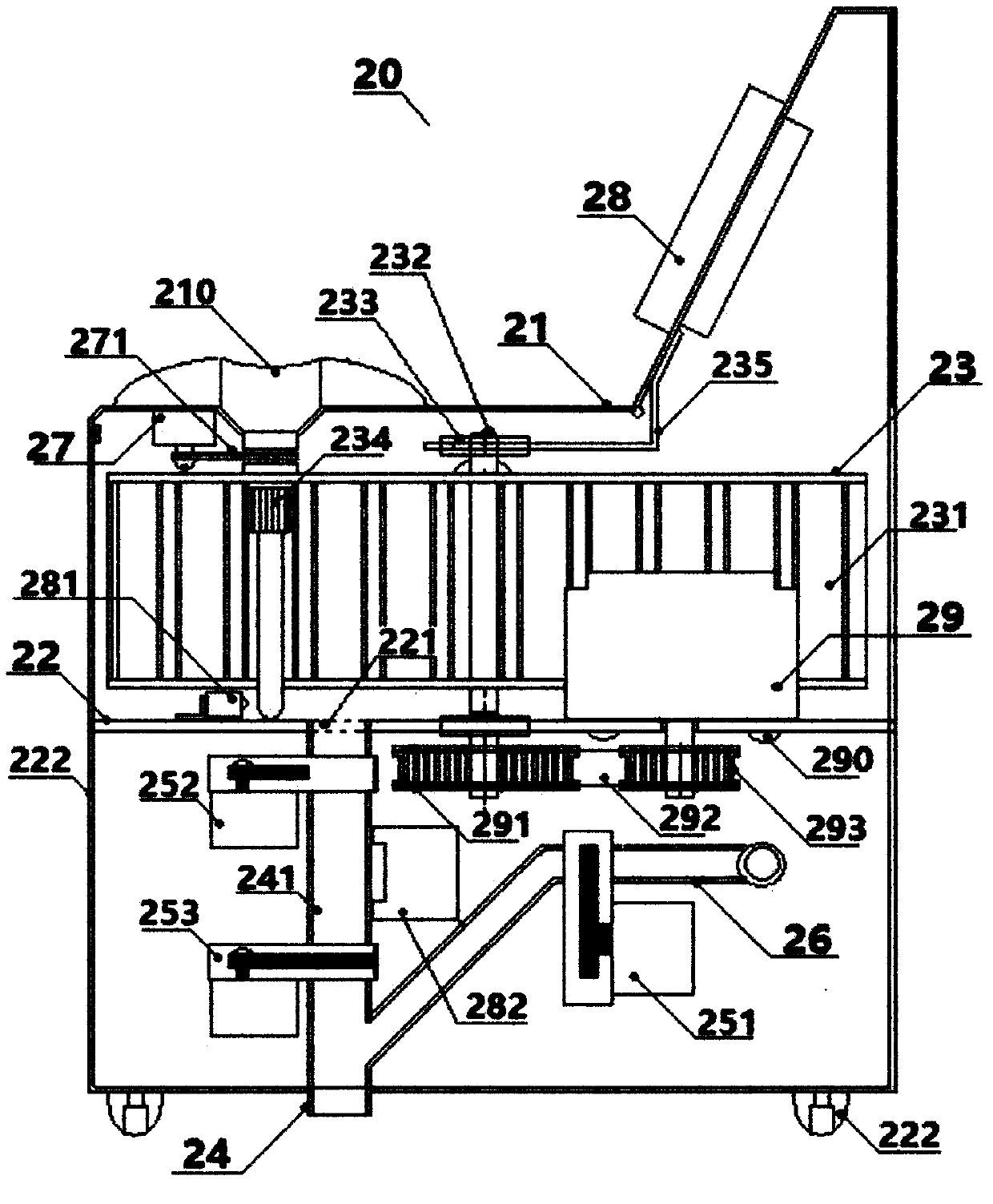

[0018] The sending workstation is composed of a platen 21, a test tube supporting plate 22, a rotating body 23, a transmission pipeline, an electric control pipeline valve 25, a pressure gas pipe 26, a micromotor 27 at the feeding port, a reading device 28, and a driving motor 29 for the rotating body.

[0019] The delivery station platform 21 is provided with a test tube drop-in port, and the micro-motor 27 driving the drop-in port cover plate 271 is equipped with below the drop-in port 270, see figure 1 , figure 2 .

[0020] The rotating body 23 is positioned by the storage bins 231 of the same height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com