Transfer mechanism and transfer equipment

A technology of transferring and sliding parts, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that the manipulator is not suitable for transferring multiple materials, the utilization rate of turntable space is low, and the conveyor belt is uncomfortable. High speed, simple structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

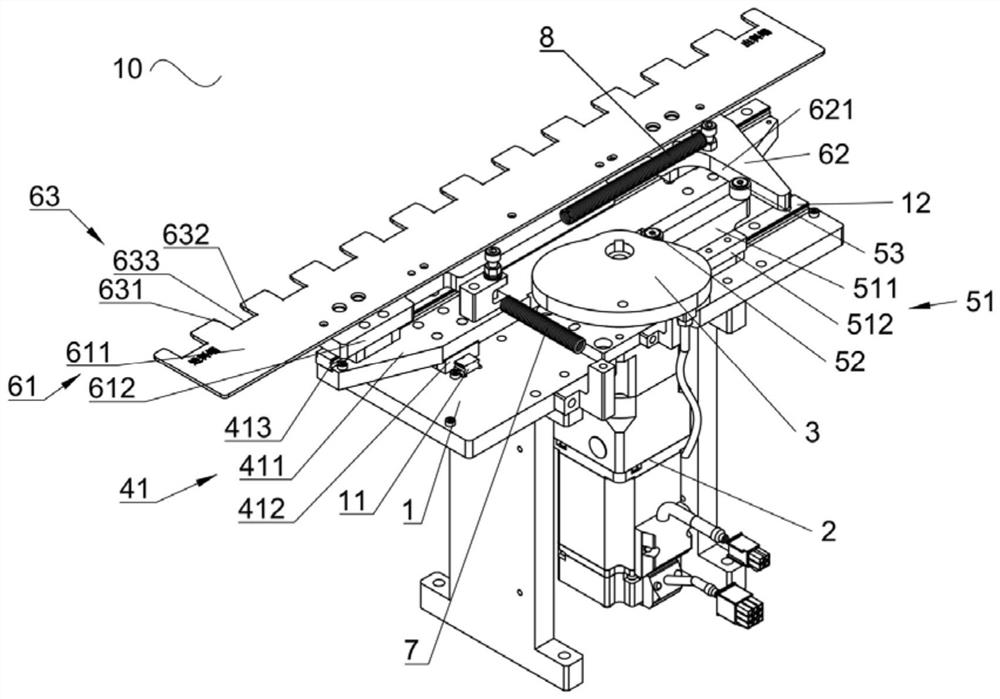

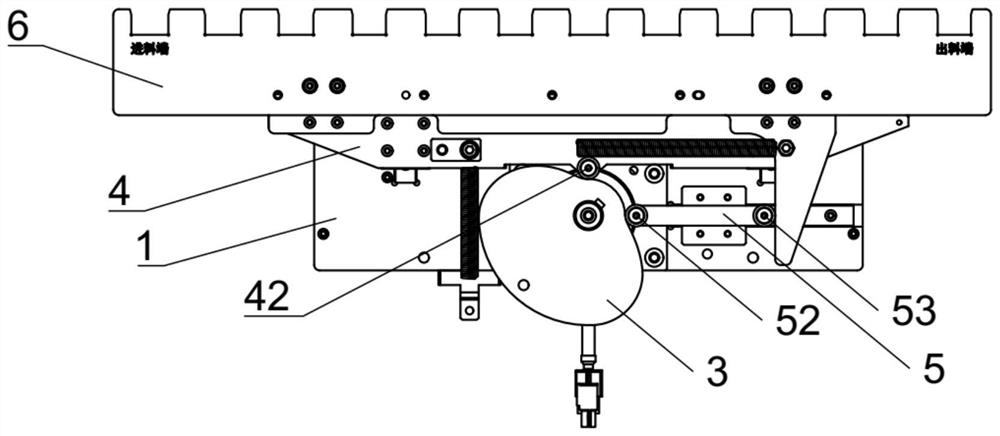

[0050] refer to figure 1 , figure 2 , a transfer mechanism 10, which is used to transfer materials, the transfer mechanism 10 includes a base 1, a rotary drive member 2, a rotary member 3, a first sliding member 4, a second sliding member 5, a transfer member 6, The first reset member 7 and the second reset member 8.

[0051] Base 1, the base 1 is provided with two first slide rails 11 extending along the first direction and a second slide rail 12 extending along the second direction;

[0052] When the driving member 2 is rotated, the output end of the rotary driving member 2 rotates around the first axis, and the first axis, the first direction and the second direction are perpendicular to each other. Specifically, the rotating driving member 2 is a servo motor, and the transmission is stable. The casing of the servo motor is fixed on the base 1 for stable installation.

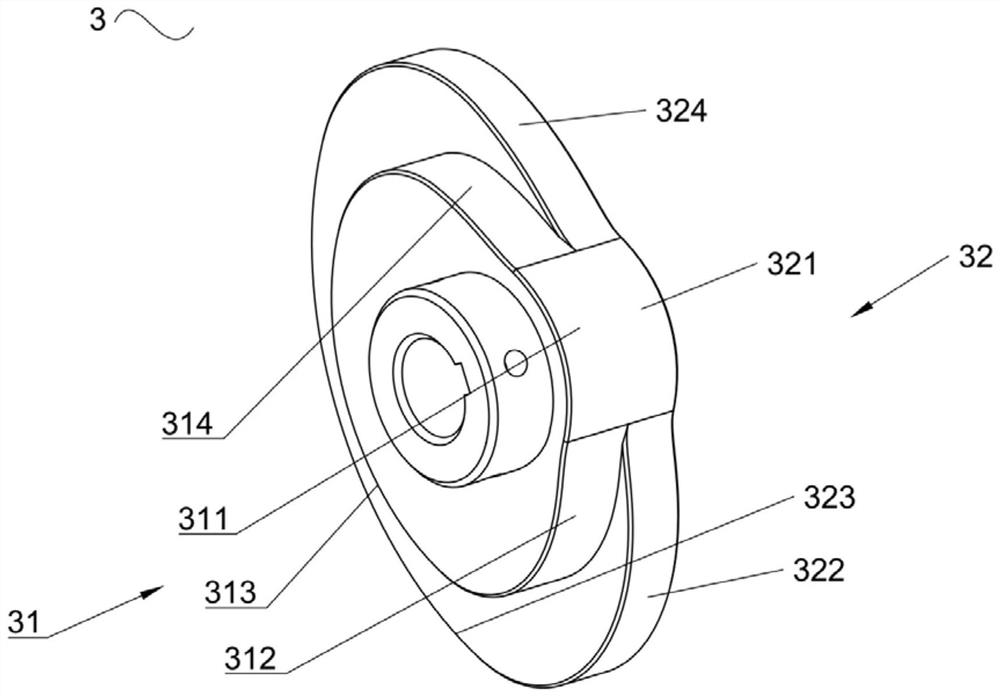

[0053] The rotating member 3 is fixedly connected with the output shaft of the rotating driving memb...

Embodiment 2

[0070] refer to Figure 5 , a transfer device, comprising a carrier 20 and the above-mentioned transfer mechanism 10, the carrier 20 extends along the second direction and is used to carry materials to assist the transfer mechanism 10 to transfer the materials, and the carrier 20 is provided with The chute 201 extends along the second direction. The chute 201 opens upward and is suitable for the material to extend so that the material can be transferred by the transfer mechanism 10. The bottom wall of the chute 201 forms a bearing surface. When the material is placed in the chute 201, the movement of the material in the first direction is restricted to prevent the material from running. Further, the chute 201 and the limiting surface 632 cooperate together to determine the stepping distance of the material during the movement process, and it will not be easily Offset to achieve precise positioning, which is convenient for the next detection or processing of materials.

[0071...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com