Door leaf with movable window frame and manufacturing method

A movable type and window frame technology, which is applied in the direction of door devices, mechanical equipment, railway car body parts, etc., can solve the problems of difficult matching, less glue amount, glue overflow, etc., and achieve better quality, uniform gap size, and assembly high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

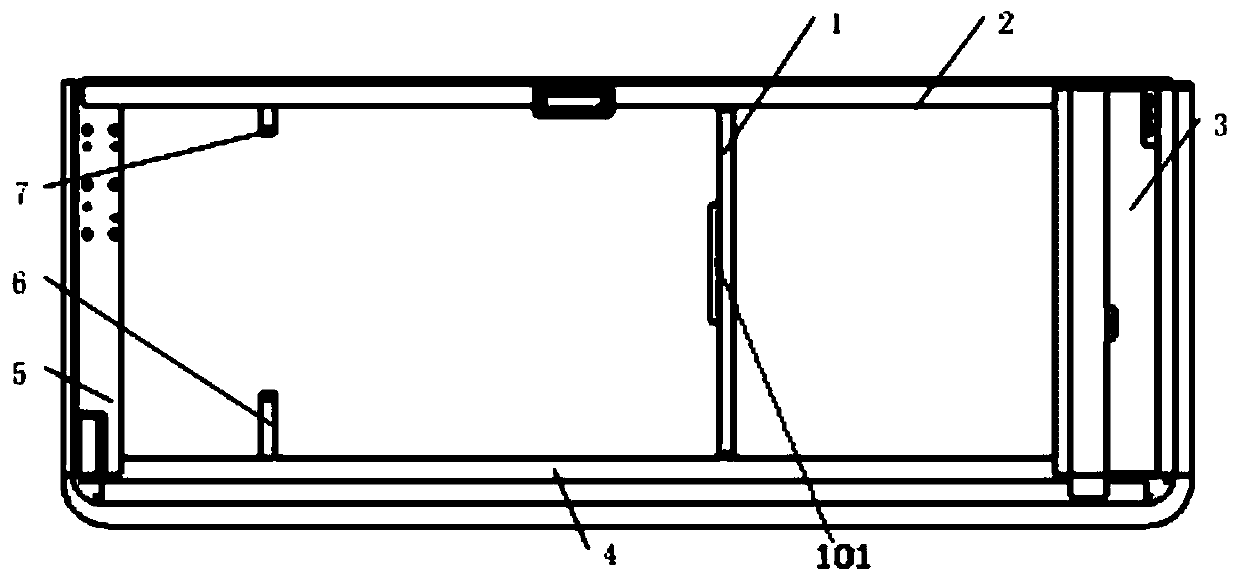

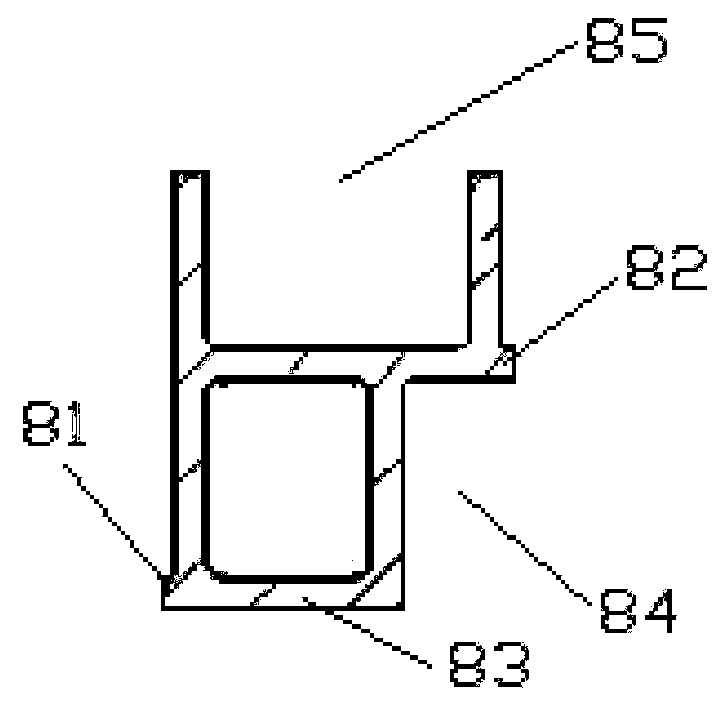

[0030] Such as Figure 1 to Figure 4 As shown: this embodiment discloses a door leaf with a movable window frame: including a door panel frame and a window assembly connected to the door panel frame, the window assembly includes a window frame 8, an outer skin 9, an inner skin 10, and honeycomb aluminum 11 And the hollow glass 12, the outer edge and the inner edge of the window frame 8 are respectively provided with a honeycomb aluminum connection surface 85 for connecting the edge of the honeycomb aluminum 11, and a hollow glass connection surface 83 for connecting the hollow glass 12, and the hollow glass connection surface 83 is also provided with The hollow glass tank 84, the two sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com