Tolerance-compensation frame for joining around headlamps

A technology of tolerance compensation and frame, applied in the direction of bicycle frame, vehicle parts, bicycle accessories, etc., can solve problems such as increasing cost and increasing time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

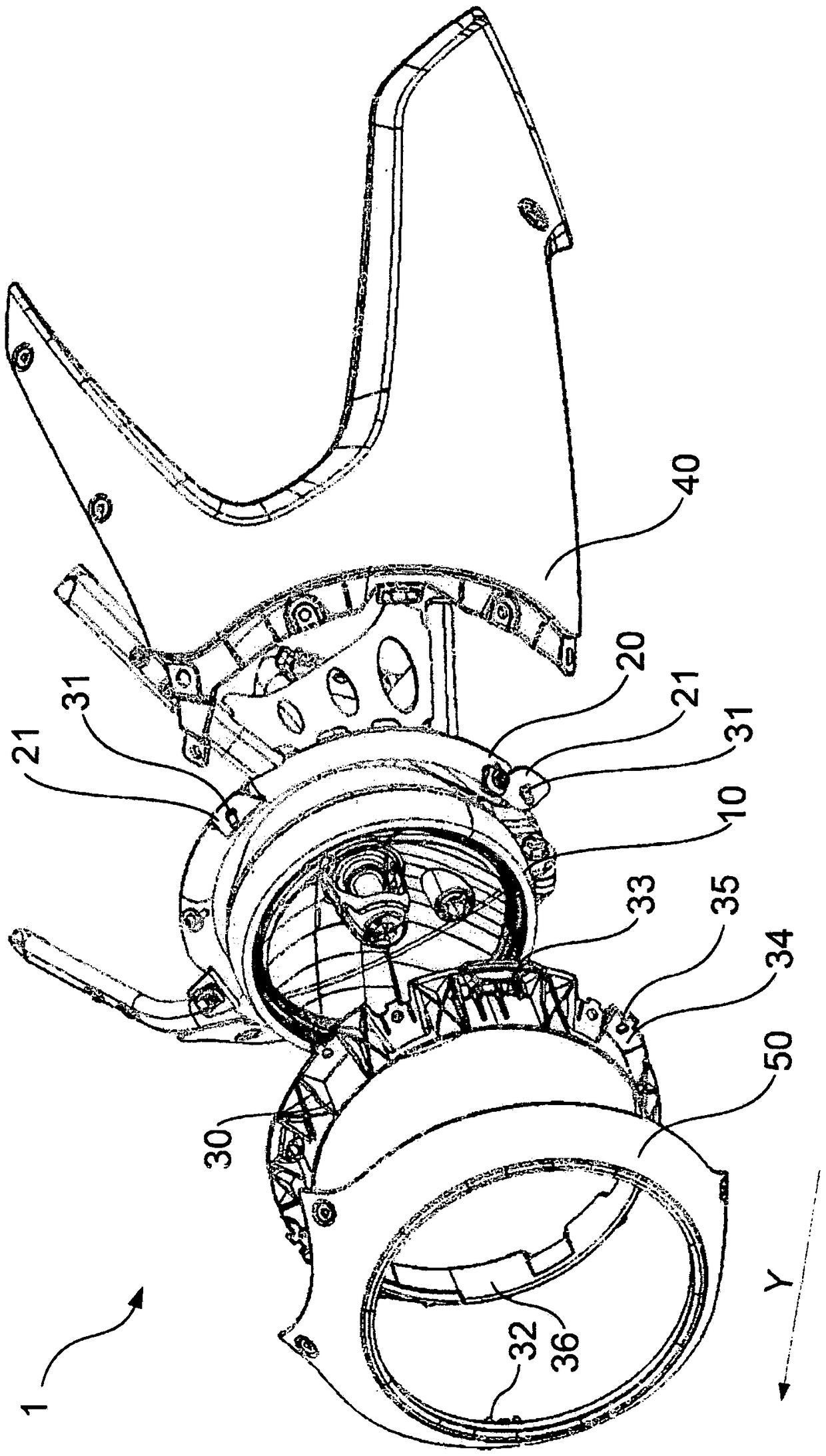

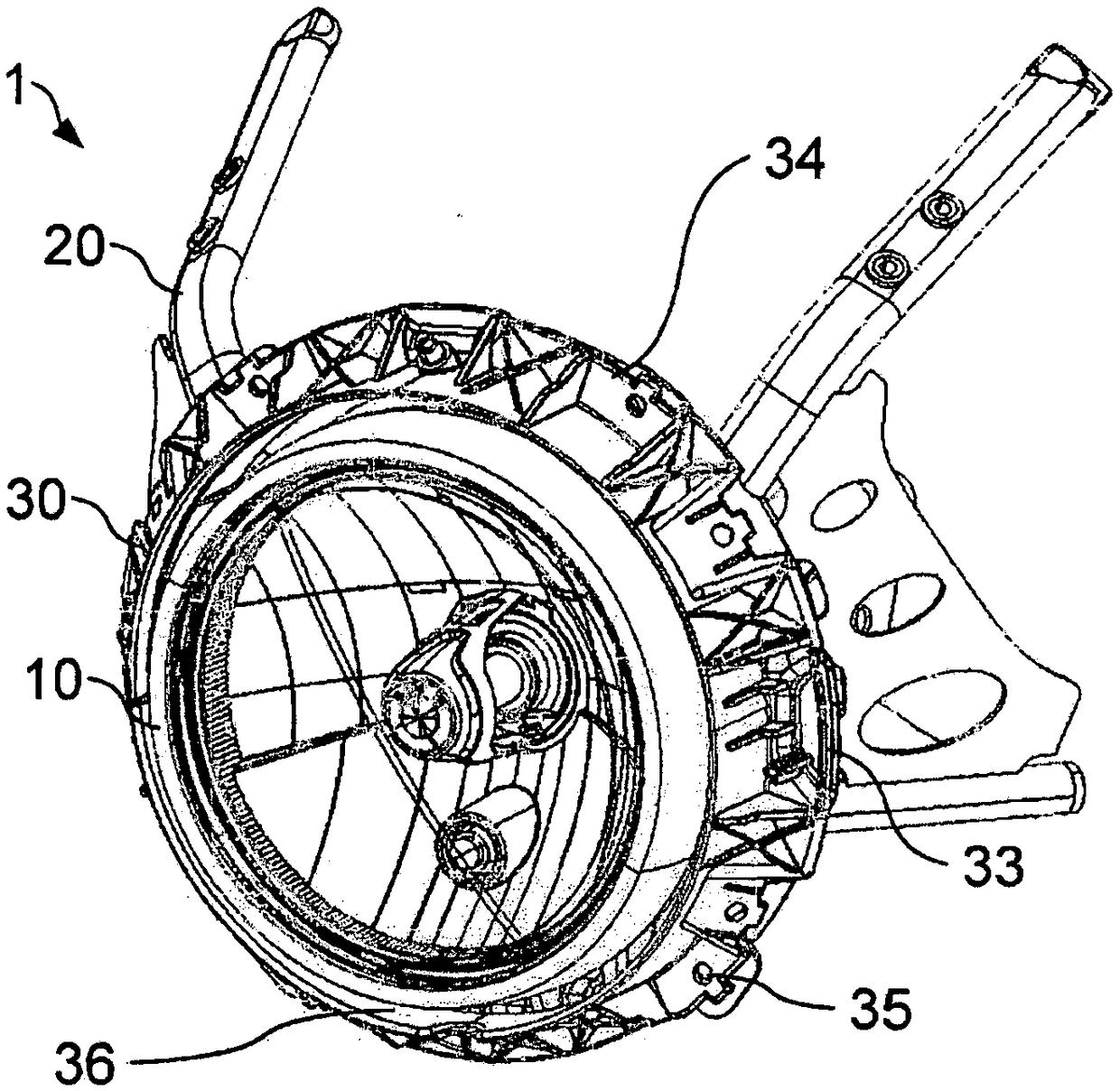

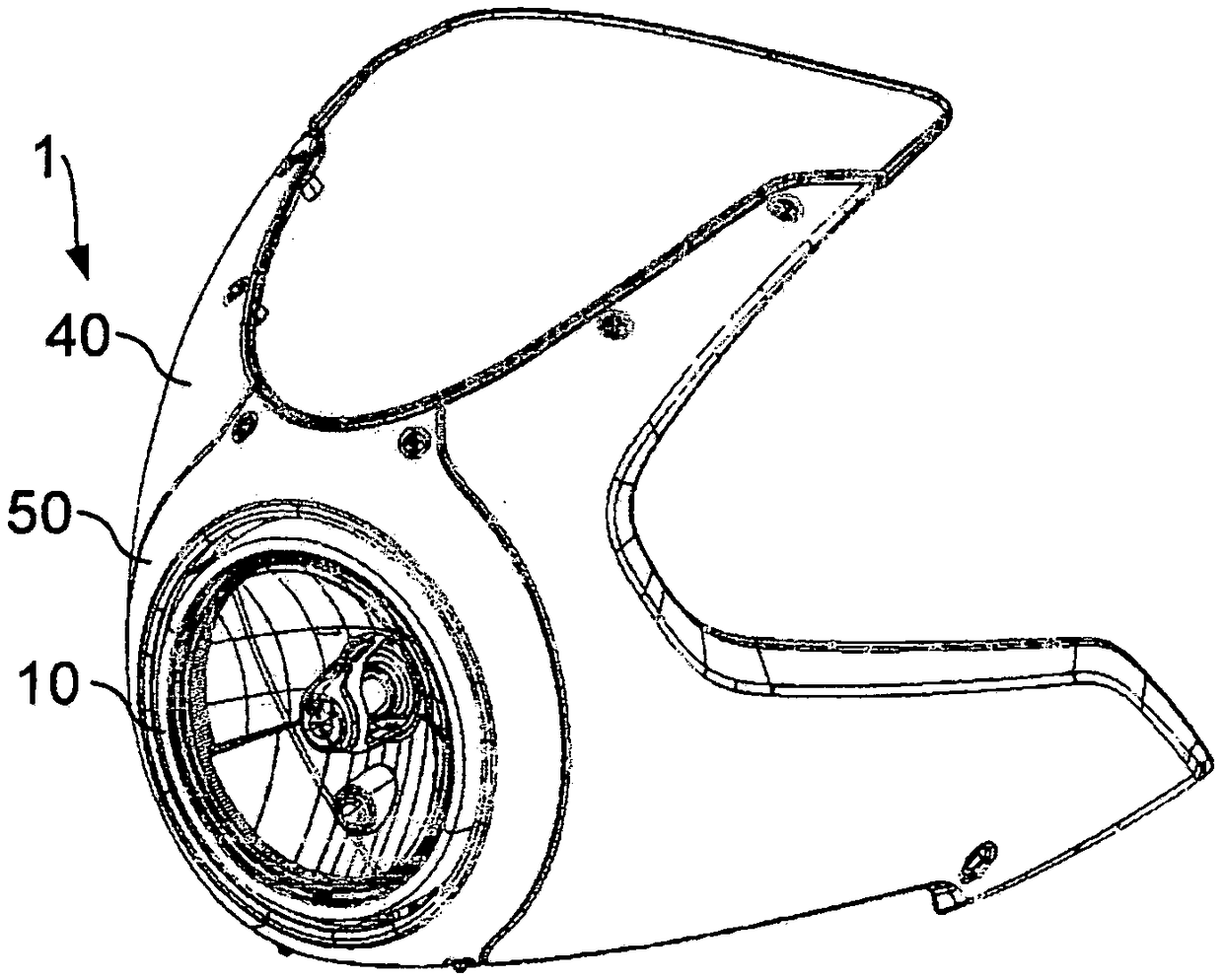

[0027] exist figure 1The tolerance compensation device 1 is shown in . The motorcycle frame element 20 with the already assembled motorcycle light 10 can be seen. The motorcycle trim 40 , the tolerance compensation frame 30 and the cover unit 50 are shown in an exploded and spaced manner from it (the motorcycle frame element with the already assembled motorcycle light). The motorcycle frame element 20 is configured as a substantially torus-shaped and C-shaped frame for the motorcycle light 10, wherein, from the torus-shaped portion of the motorcycle frame element 20, tongues 21 are configured for fastening. A solid tolerance compensating frame 30, or tongues are connected via a connection mechanism such as welding. The tongues 21 each have an elongated hole extending in the tolerance compensation direction Y. The later possible movement stroke along the tolerance compensation direction Y depends on the length of the long hole. The motorcycle frame element 20 is also formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com