Automatic assembly line production system of coupler

A production system and coupler technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as unfavorable batch production, non-conformity, and low efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

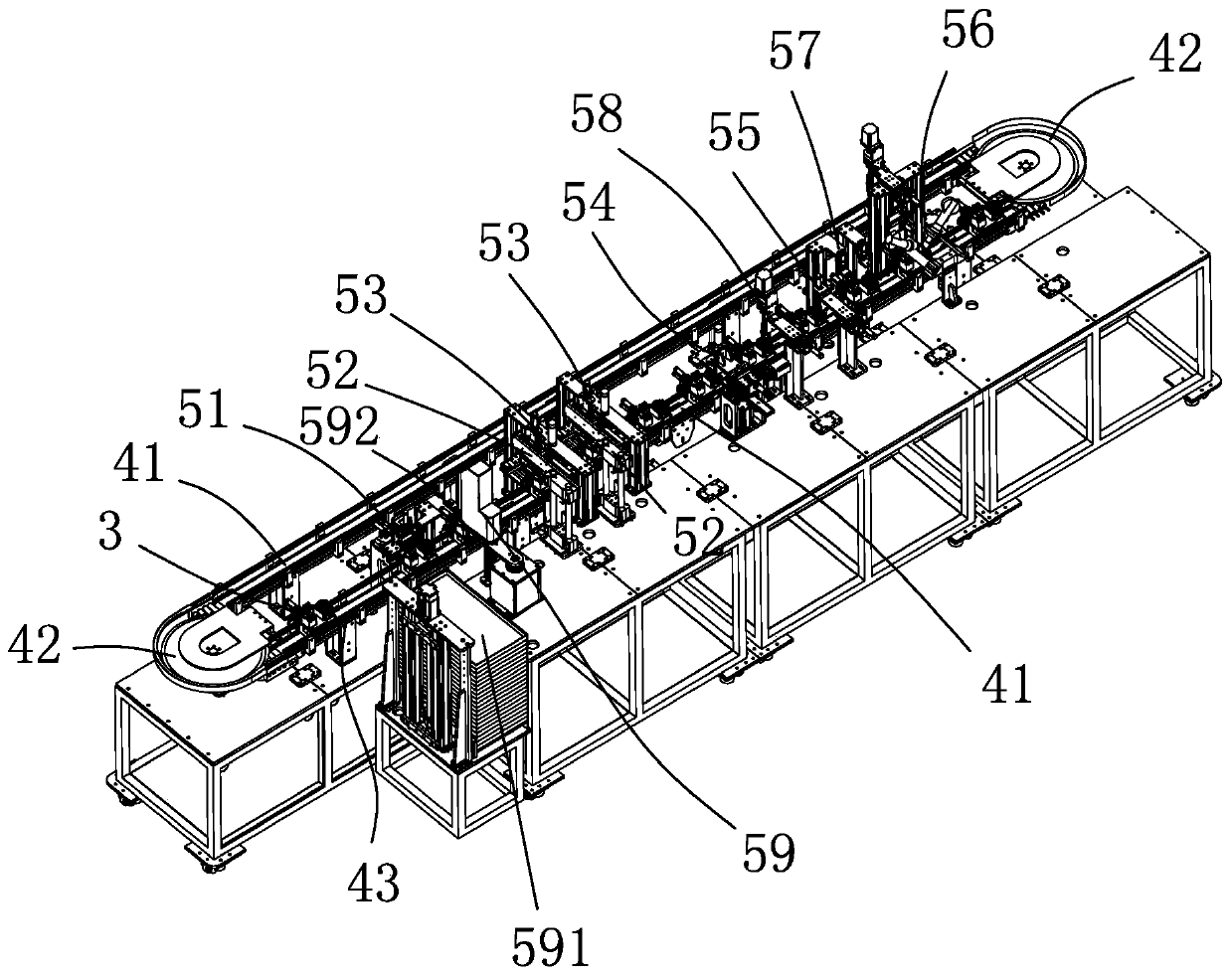

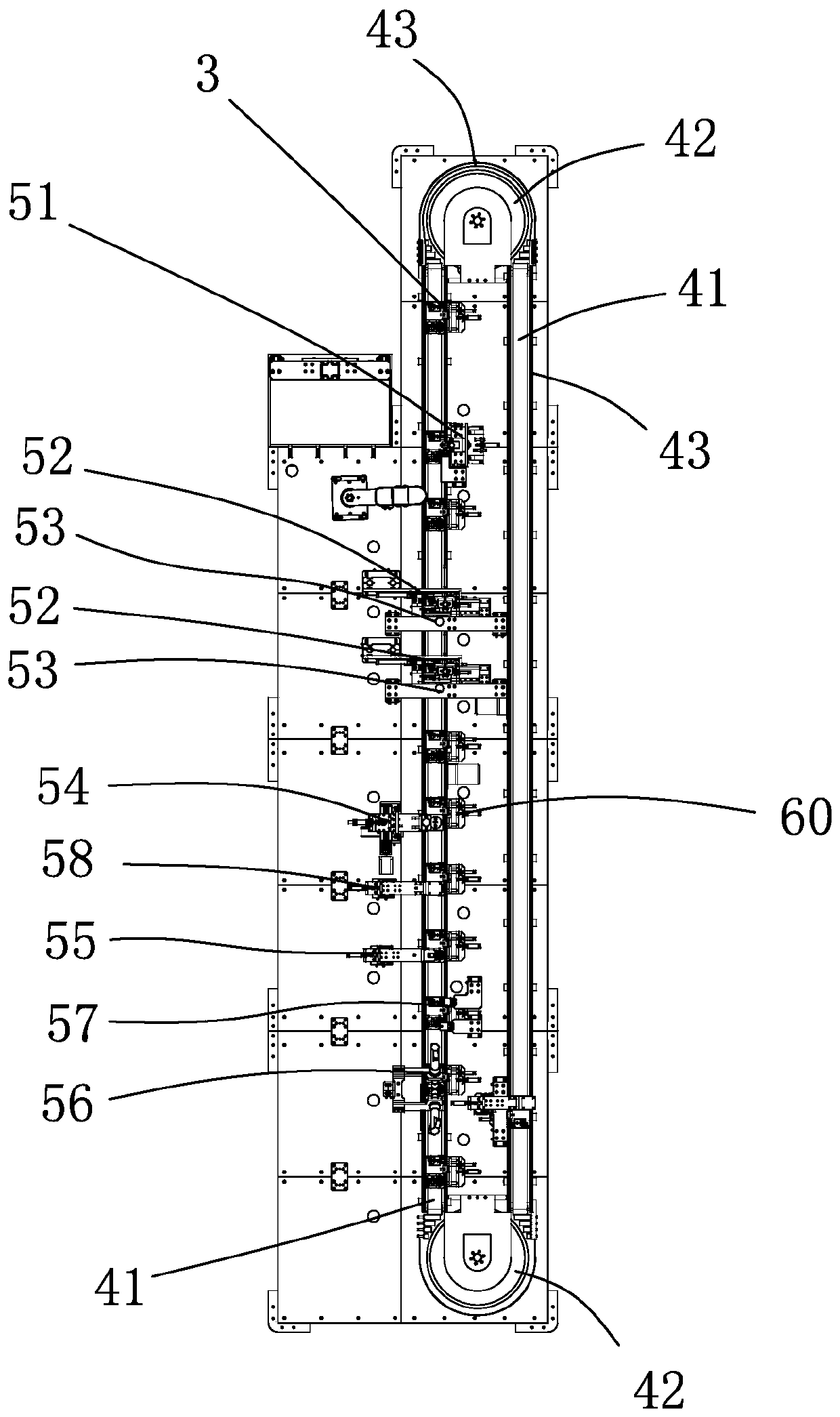

[0038] A new type of coupler developed by the applicant, such as figure 1 As shown: it includes a base 1 made of plastic and a power cord 2 connected to the base 1. The base 1 is provided with three conductive sheets 11, and the three conductive sheets 11 are respectively arranged corresponding to the ground wire, live wire and neutral wire. The power line 2 then includes a bus 21 and three branch lines 22. The three branch lines 22 are separated from one end of the bus 21 and connected to the terminals of the three conductive sheets 11 correspondingly. The exposed part of the copper wire is connected with riveting. There is a riveting place 10 between the conductive sheet 11 and the branch line 22. The other end of the bus 21 is connected to a plug 23. The exposed part of the copper wire at the end of the branch line 22 is riveted with the terminal of the conductive sheet 11. , welding, heat shrinkable tubes 20 are sleeved at the joints of the branch lines corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com