An automatic production line for steel back surface treatment

An automatic production line and surface treatment technology, applied in the field of brake pad production, can solve the problems of increasing market demand and restricting the production efficiency of steel backs, and achieve the effect of improving efficiency, realizing quality control, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0044] In describing the present invention, it is to be understood that the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", " Back", "Left", "Right", "Vertical", "Horizontal", "Top", "Bottom", "Inner", "Outer", "Clockwise", "Counterclockwise", "Axial", The orientation or positional relationship indicated by "radial", "circumferential", etc. is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying the referred device or element Must be in a particular orientation, be constructed in a particular orientation, and operate in a particular orientation, and therefore should not be construed as limiting the invention.

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in de...

specific Embodiment 1

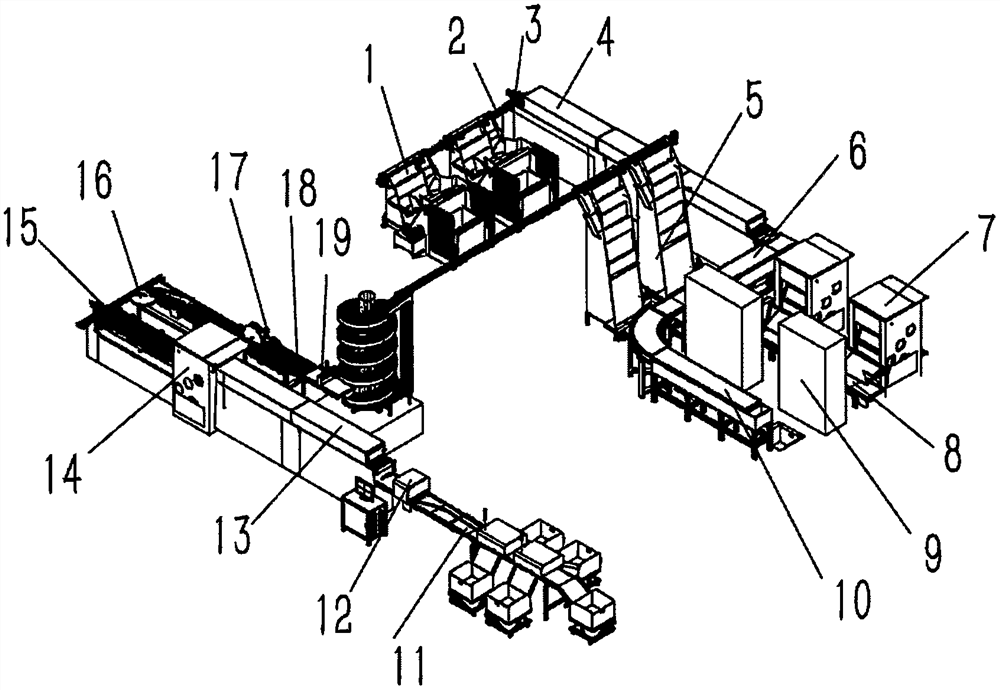

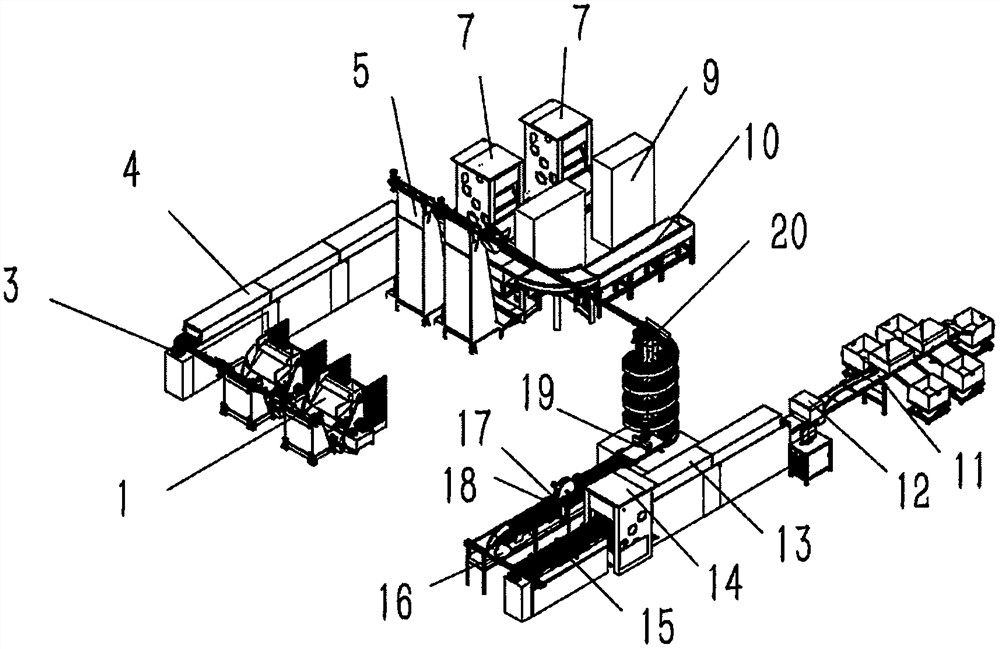

[0048] An automatic steel back surface treatment production line is used to transform the existing steel back surface treatment production line. The existing equipment includes a steel back cleaning machine 4, a steel back sandblasting machine 7 and a steel back glue spraying machine 14, and the steel back glue spray machine is also Equipped with a dryer 13, it is used to dry and solidify the spray glue on the surface of the steel back, and the automatic production line for the surface treatment of the steel back, according to the production sequence, it also includes:

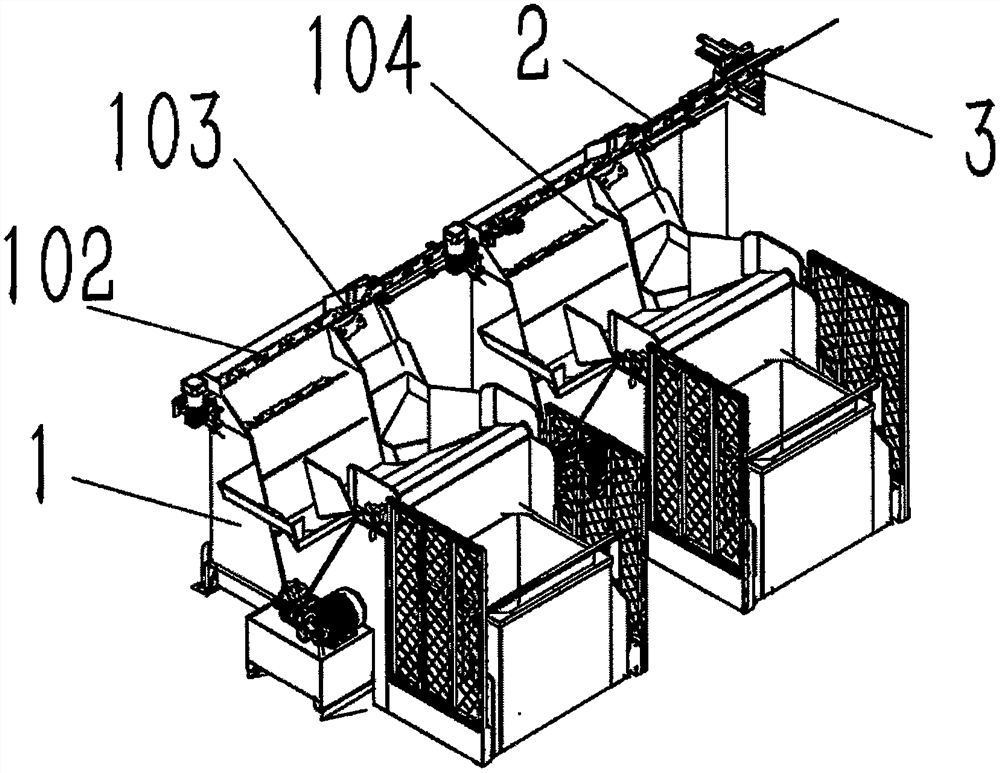

[0049] Automatic feeding and conveying device, the automatic feeding and conveying device includes an automatic feeding machine 1 and a steel back conveyor 2, the automatic feeding machine 1 includes a hopper 101 and an automatic sorting device 102, and the automatic sorting device 102 is provided with a multi-stage push plate 103 , the multi-stage push plate 103 is driven by the same cam, when the cam turns to...

specific Embodiment 2

[0060] On the basis of Embodiment 1, the drying and unloading sorting device includes an end plate chain conveyor 11 and a finished product sorting device 12 arranged on the end plate chain conveyor, and a sorting vision system is arranged in the finished product sorting device 12 And the module plate chain conveyor, control the rotation of the guide roller under the module plate chain according to the photo comparison results of the sorting vision system, and guide the corresponding steel back into the finished product material basket before the specified finished product material basket, the module plate chain conveyor The chain plate of the modular plate chain is provided with through holes arranged in a matrix, and balls are arranged in the through holes. When the guide roller under the module plate chain rotates, the balls are driven to rotate. Since the top of the ball is higher than the plane of the chain plate, so It moves sideways with the steel back, and finally slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com