Forming die set of sliding rail rolling mill

A forming die and rolling mill technology, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of poor bonding strength between heterogeneous materials, affecting the bonding state of steel bars and aluminum seats, Problems such as shortened service life of linear slide rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

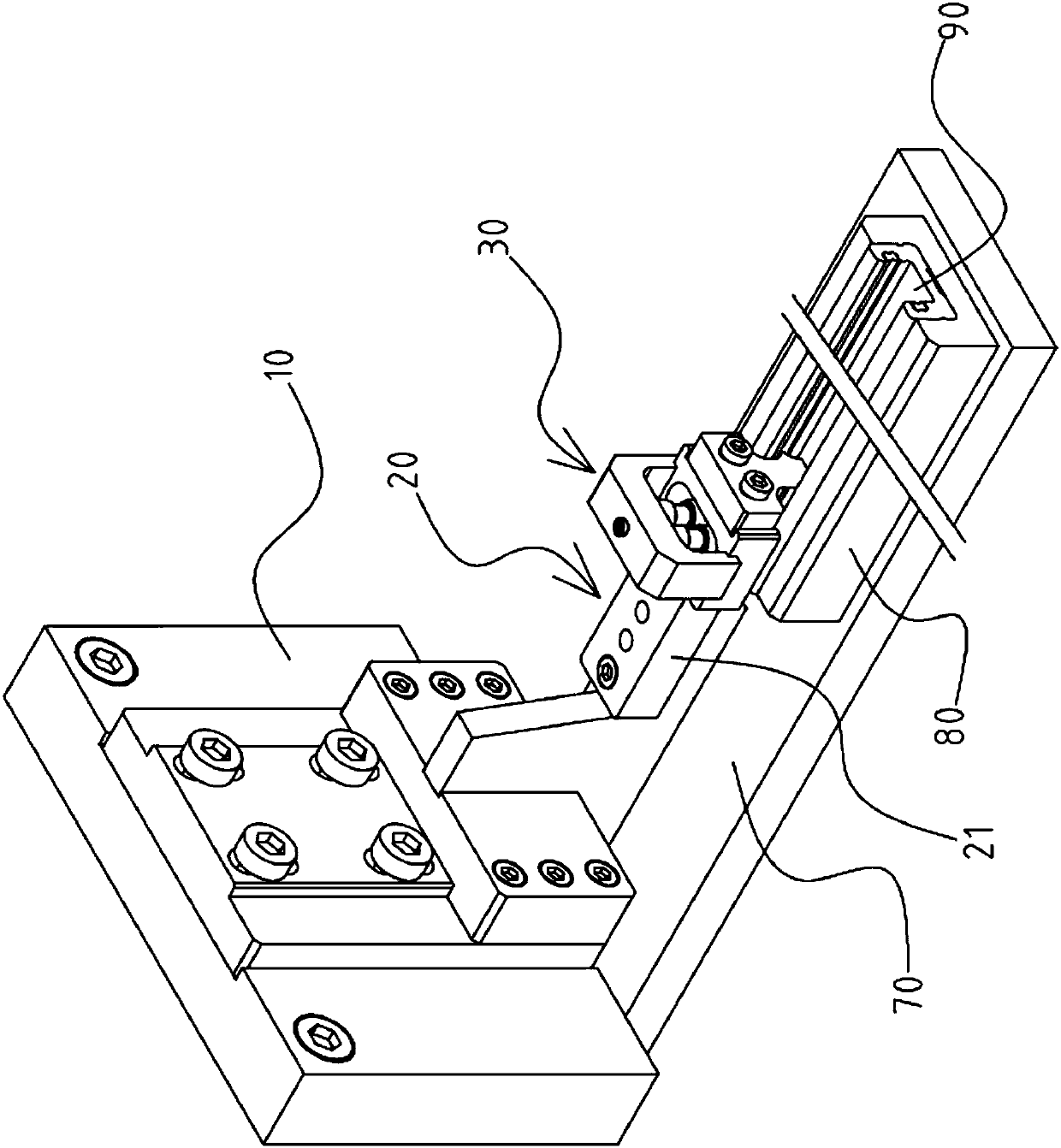

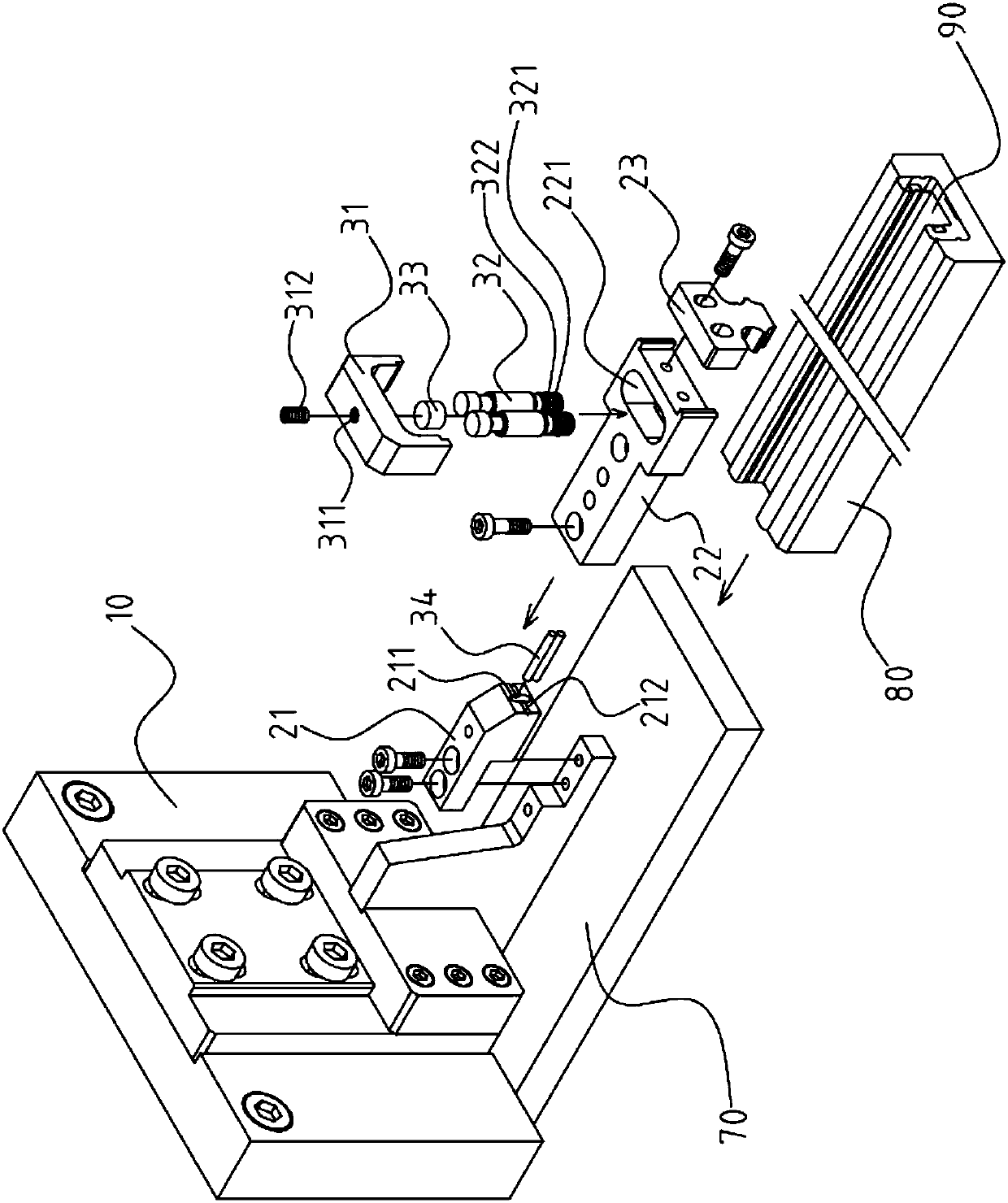

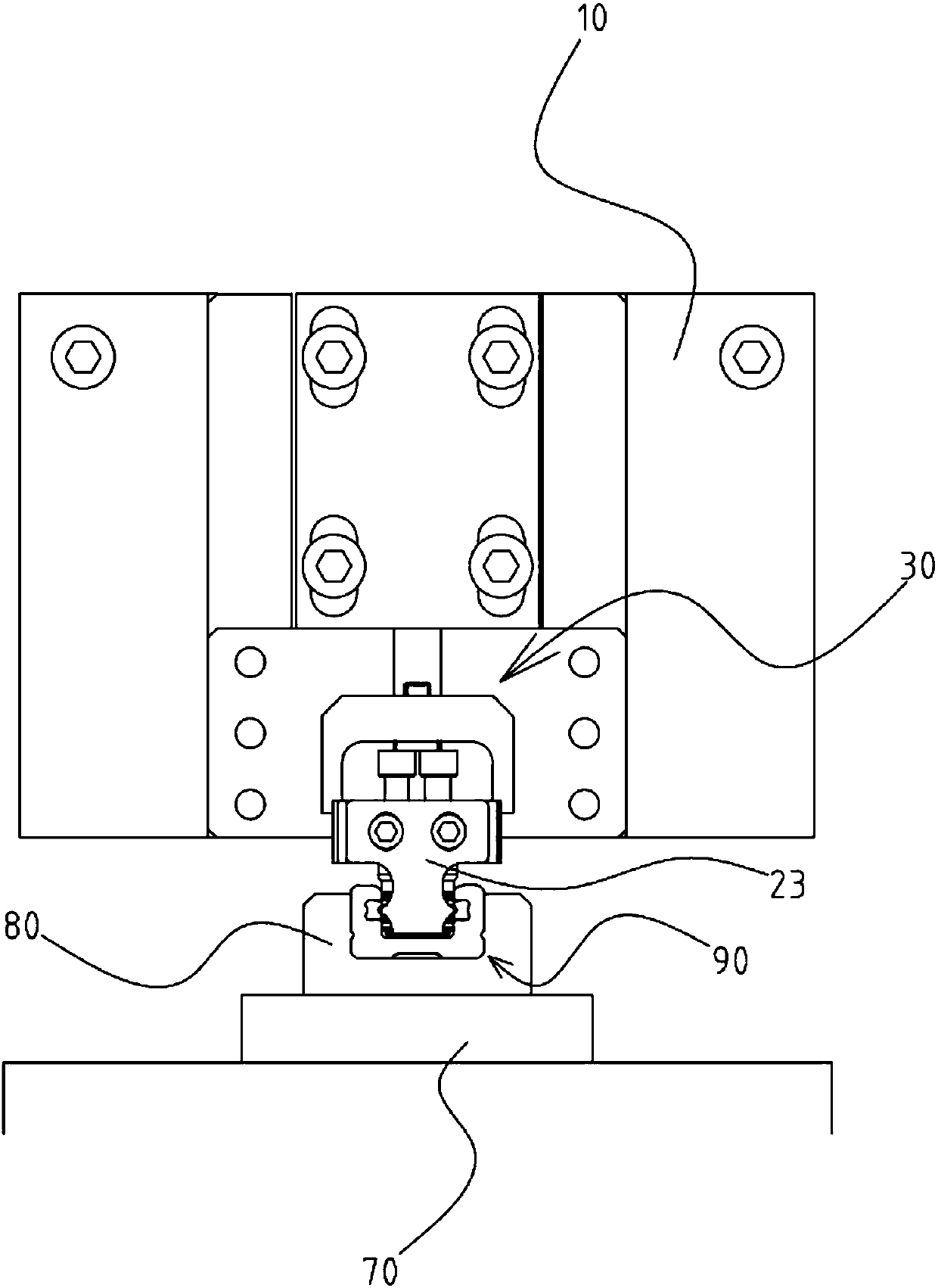

[0021] Such as figure 1 , 2 , 3, 4, and 5, the forming die set of the slide rail rolling machine of the present invention includes a mounting base 10 for being fixed on the working machine (not shown in the figure), and a mounting base 10 detachably mounted on the mounting base 10. The rolling die 20 above, and for the convenience of operation, the present invention further includes a fixture 80 for sliding on a platform 70, wherein the platform 70 and the mounting seat 10 are arranged at intervals, and a slide rail 90 is formed between the two Cooperate with the feed space 40 for axial rolling movement of the jig 80 .

[0022] The mold 20 includes a connecting piece 21 fixed on the mounting base 10, a base 22 mounted on the connecting piece 21, at least one rolling die 30 mounted on the base 22, and a The guide block 23 of body 22 front ends. A first groove 211 is formed axially on the end surface of the connecting member 21 ; a through groove 221 is formed on the base 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com