Beta-tricalcium phosphate porous ceramic drug-loading stent and preparation method and application thereof

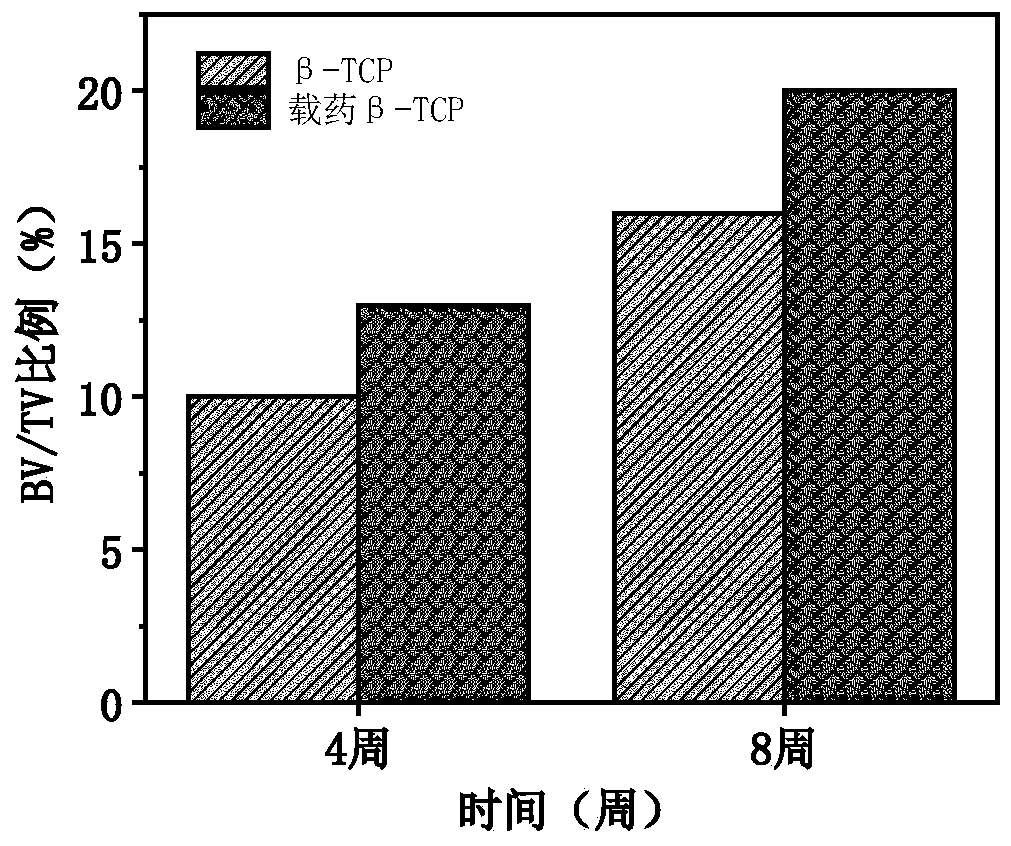

A technology of tricalcium phosphate and porous ceramics, applied in ceramic products, applications, and other household appliances, etc., can solve the problems of slow tissue repair effect and single function, achieve good bone repair effect, fast release, reduce and avoid inflammation and The effect of the immune response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

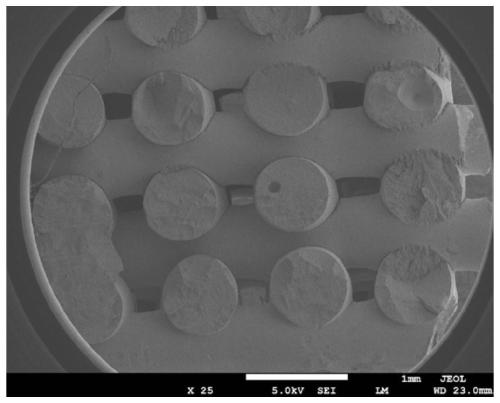

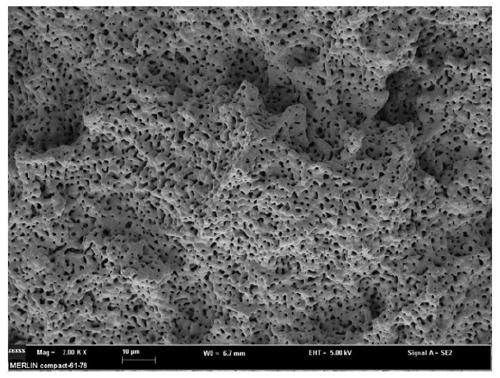

[0030] (1) 30g of β-tricalcium phosphate, 18g of sodium alginate solution with a mass concentration of 10%, 3g of Pluronic F-127 solution with a mass concentration of 30%, and 7g of ultrapure water were evenly stirred through a ball mill to obtain a 3D printed product. Ink: Put the 3D printing ink into the 3D printing equipment, design a cylindrical printing model with a diameter of 8mm and a height of 10mm, use a nozzle with a diameter of 0.41mm, an air pressure of 0.5MPa, a printing speed of 3mm / s, a layer thickness of 0.4mm, and an adjacent distance of The printing parameters of 0.8mm are printed by 3D printing equipment and dried at room temperature for 24 hours;

[0031] (2) Put the printed stent into the muffle furnace, the sintering system is: 5°C / min from room temperature to 500°C, heat preservation for 0.5 hours; 10°C / min from 500°C to 1100°C, heat preservation for 0.5 hours ;Rapidly cool down to 800°C at 10°C / min, hold for 2 hours, and cool with the furnace to obtain...

Embodiment 2

[0041](1) Mix 44g of β-tricalcium phosphate, 25g of sodium alginate solution with a mass concentration of 20%, 9g of Pluronic F-127 solution with a mass concentration of 20%, and 3g of ultrapure water through a ball mill to obtain a 3D printed product. Ink: Put the 3D printing ink into the 3D printing equipment, design a cylindrical printing model with a diameter of 8mm and a height of 10mm, use a nozzle with a diameter of 0.41mm, an air pressure of 0.5MPa, a printing speed of 3mm / s, a layer thickness of 0.4mm, and an adjacent distance of The printing parameters of 0.4mm are printed by 3D printing equipment and dried at room temperature for 24 hours;

[0042] (2) Put the printed stent into the muffle furnace, the sintering system is: 5°C / min from room temperature to 550°C, heat preservation for 2 hours; 10°C / min from 550°C to 1000°C, heat preservation for 2 hours ;Rapidly cool down to 900°C at 10°C / min, keep it warm for 2 hours, and cool with the furnace to obtain a β-tricalci...

Embodiment 3

[0049] (1) 30g β-tricalcium phosphate, 20g mass concentration of 10% sodium alginate solution, 5g mass concentration of 20% Pluronic F-127 solution are stirred evenly by ball milling to prepare 3D printing ink; 3D printing Put the ink into the 3D printing equipment, design a cylindrical printing model with a diameter of 8mm and a height of 10mm, use the printing parameters of a nozzle diameter of 0.41mm, air pressure of 0.5MPa, printing speed of 3mm / s, layer thickness of 0.4mm, and adjacent spacing of 0.6mm , printed by 3D printing equipment, and dried at room temperature for 24 hours;

[0050] (2) Put the printed stent into the muffle furnace, the sintering system is: 5°C / min from room temperature to 500°C, heat preservation for 1 hour; 20°C / min from 500°C to 1100°C, heat preservation for 2 hours ; 20°C / min rapid cooling to 800°C, heat preservation for 2 hours, and cooling with the furnace to obtain a β-tricalcium phosphate porous bioceramic scaffold with a macroscopic macrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com