Foodstuff supply system of intelligent kitchen and implementation method thereof

A smart kitchen and supply system technology, applied in the field of food supply systems in smart kitchens, can solve the problems of increasing labor, increasing labor intensity, unfavorable saving time and cost, etc., and achieves the reduction of labor occupation, compact structure and strong, side dishes The effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention is further described below in conjunction with accompanying drawing and embodiment:

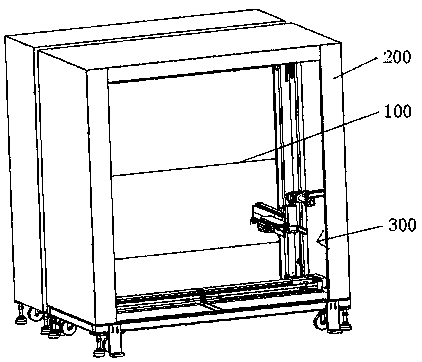

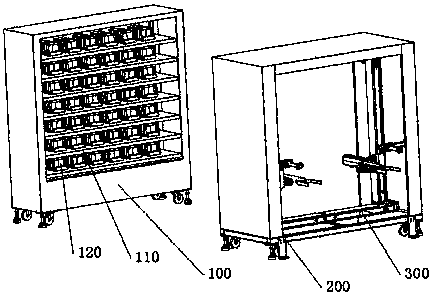

[0070] like figure 1 , figure 2 As shown, a food supply system for a smart kitchen includes a rack 200 that is side by side with a refrigerator 100 , and a food storage assembly 120 is disposed inside the refrigerator 100 .

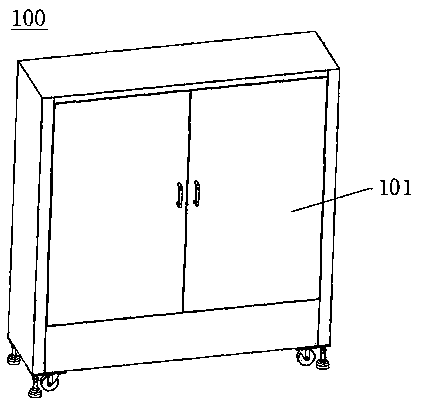

[0071] like image 3 , Figure 4 As shown, the front side of the refrigerator 100 is provided with a front door 101 , and its rear side is provided with a rear door 102 , and the rack 200 is located outside the rear door 102 . Preferably, the front door 101 is a manual sliding door, and the rear door 102 is an automatic staggered door, which is convenient for manually placing the full trays 122 and trays 121 .

[0072] like figure 2 , Figure 5 As shown, the refrigerator 100 is provided with several layers of shelves 110 , and the food material holding assembly 120 is placed on the shelves 110 . Preferably, the refrigerator 100 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com