Method and device for controlling rotating speed of roller

A technology of drum speed and control method, which is applied in the directions of adaptive control, electric controller, general control system, etc., can solve the problems of inconstant drum speed, low control accuracy of agricultural machinery drum speed, and low control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

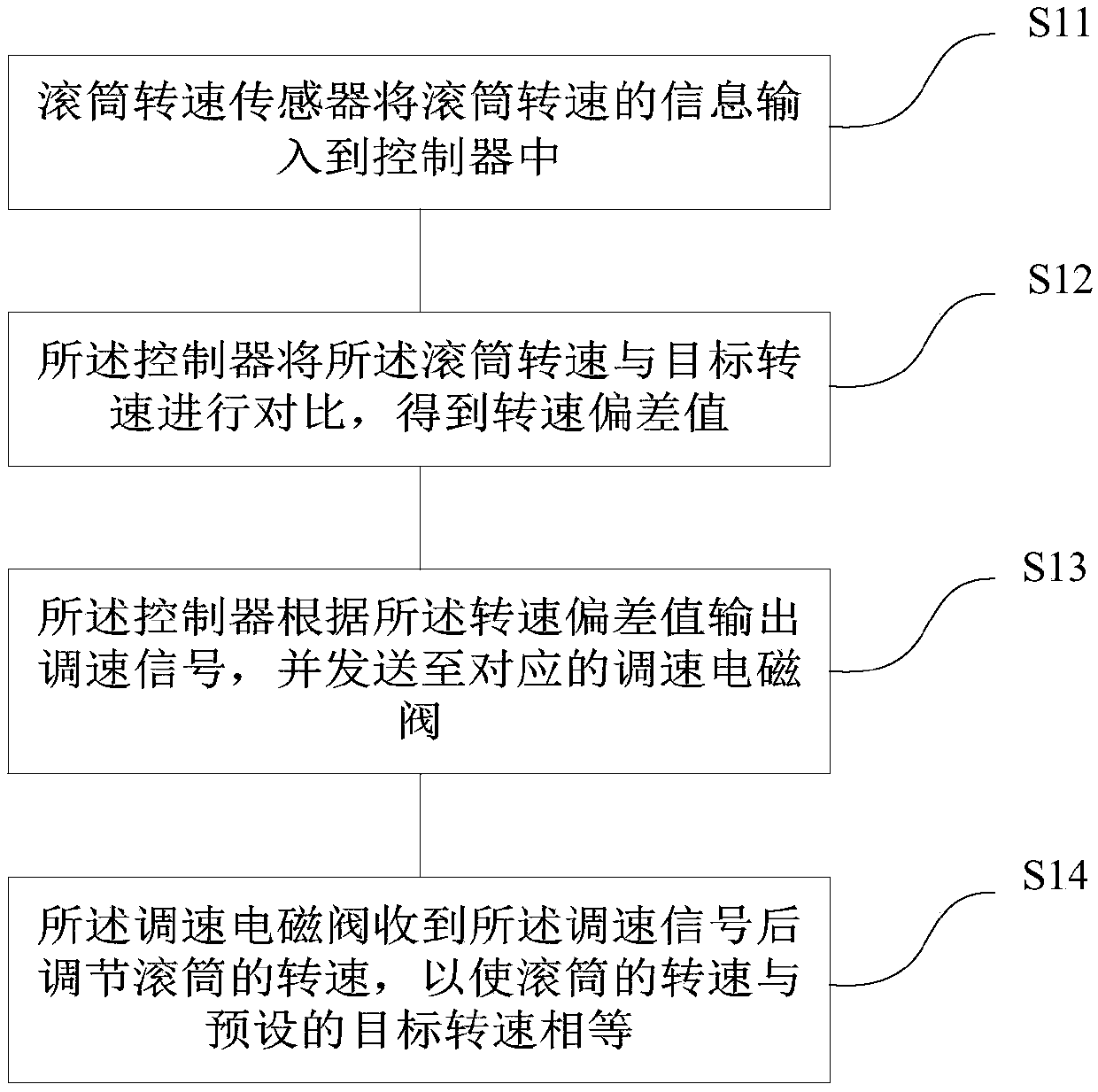

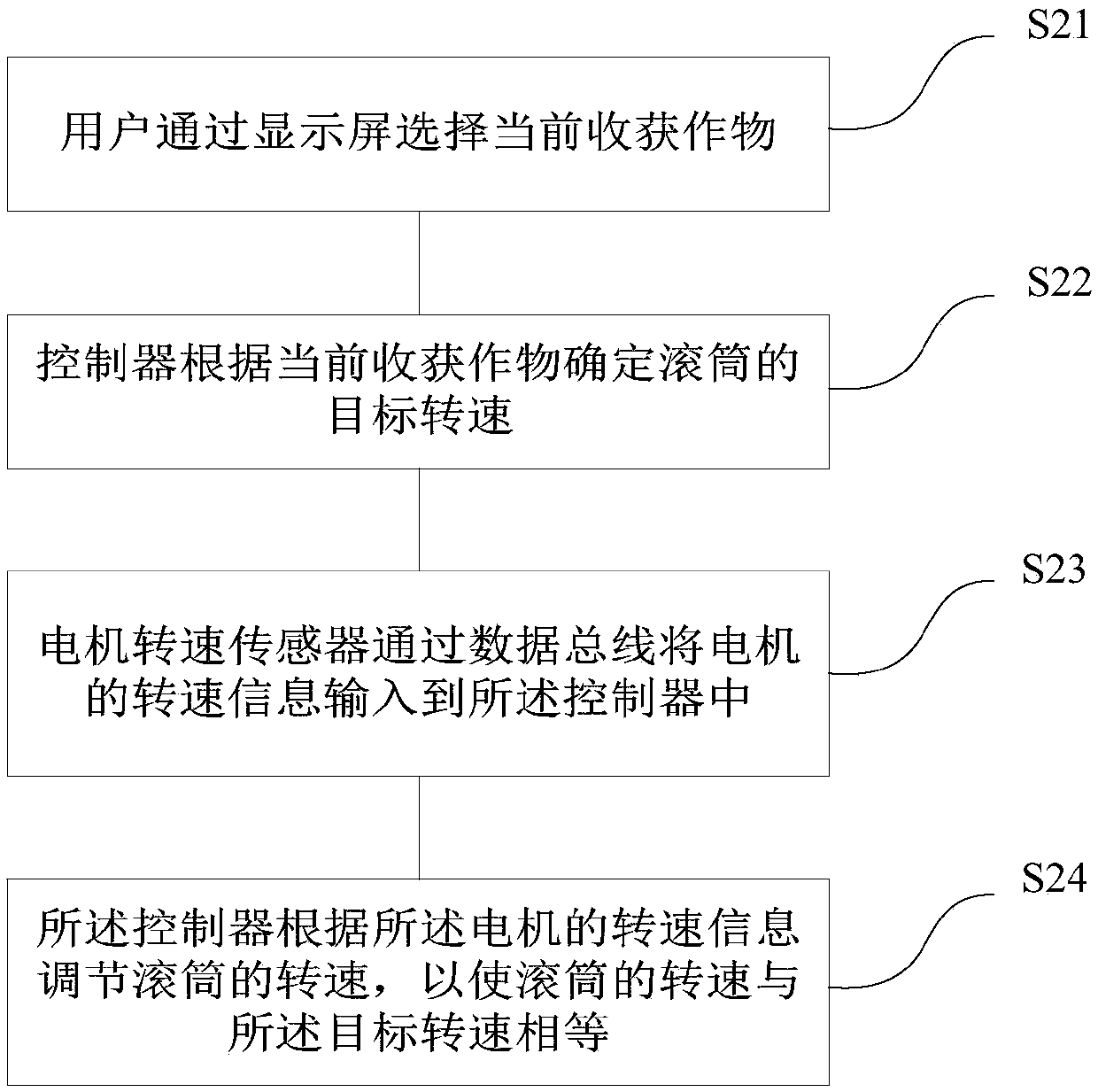

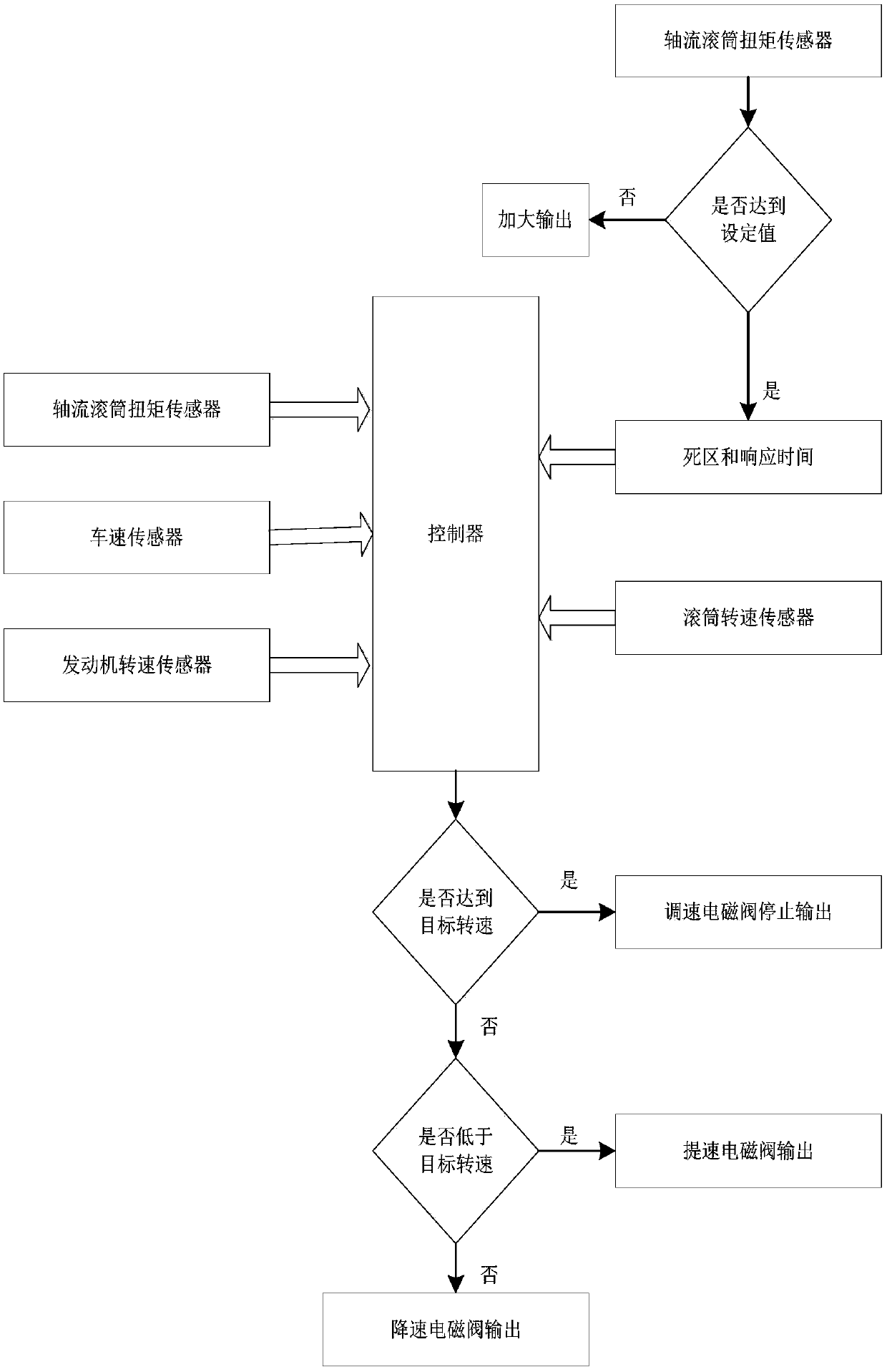

[0042] figure 1 It is a flow chart of the drum speed control method provided by the embodiment of the present invention; figure 2 It is a flow chart of the pre-steps of the drum speed control method provided by the embodiment of the present invention; image 3 It is a control logic flow chart of the method for controlling the rotational speed of the drum provided in the embodiment of the present invention.

[0043] like figure 1 As shown, in this embodiment, a drum speed control method is provided, and the drum speed control method includes the following steps:

[0044] Step S11, the drum speed sensor inputs the drum speed information into the controller;

[0045] Step S12, the controller compares the rotation speed of the drum with the target rotation speed to obtain a rotation speed deviation value;

[0046] Step S13, the controller outputs a speed regulation signal according to the speed deviation value, and sends it to the corresponding speed regulation solenoid valve...

Embodiment 2

[0070] Figure 4 It is a control principle block diagram of the drum rotation speed control device provided by the embodiment of the present invention. like Figure 4 As shown, this embodiment provides a drum speed control device, the drum speed control device includes a drum speed sensor, a speed regulating solenoid valve and a controller;

[0071] Both the drum speed sensor and the speed regulating solenoid valve are connected to the controller;

[0072] The drum speed sensor is used to input the information of the drum speed into the controller;

[0073] The controller is used to compare the rotation speed of the drum with the target rotation speed to obtain a rotation speed deviation value;

[0074] The controller is further configured to output a speed regulation signal according to the speed deviation value, and send it to a corresponding speed regulation solenoid valve;

[0075] The speed regulating solenoid valve is used to adjust the rotating speed of the drum aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com