Track operation vehicle power transmission method

A work vehicle and power transmission technology, which is applied in the field of power transmission of dual-power source-driven rail work vehicles, can solve problems such as power transmission, and achieve the effects of stable work, simple control, and fast recovery and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

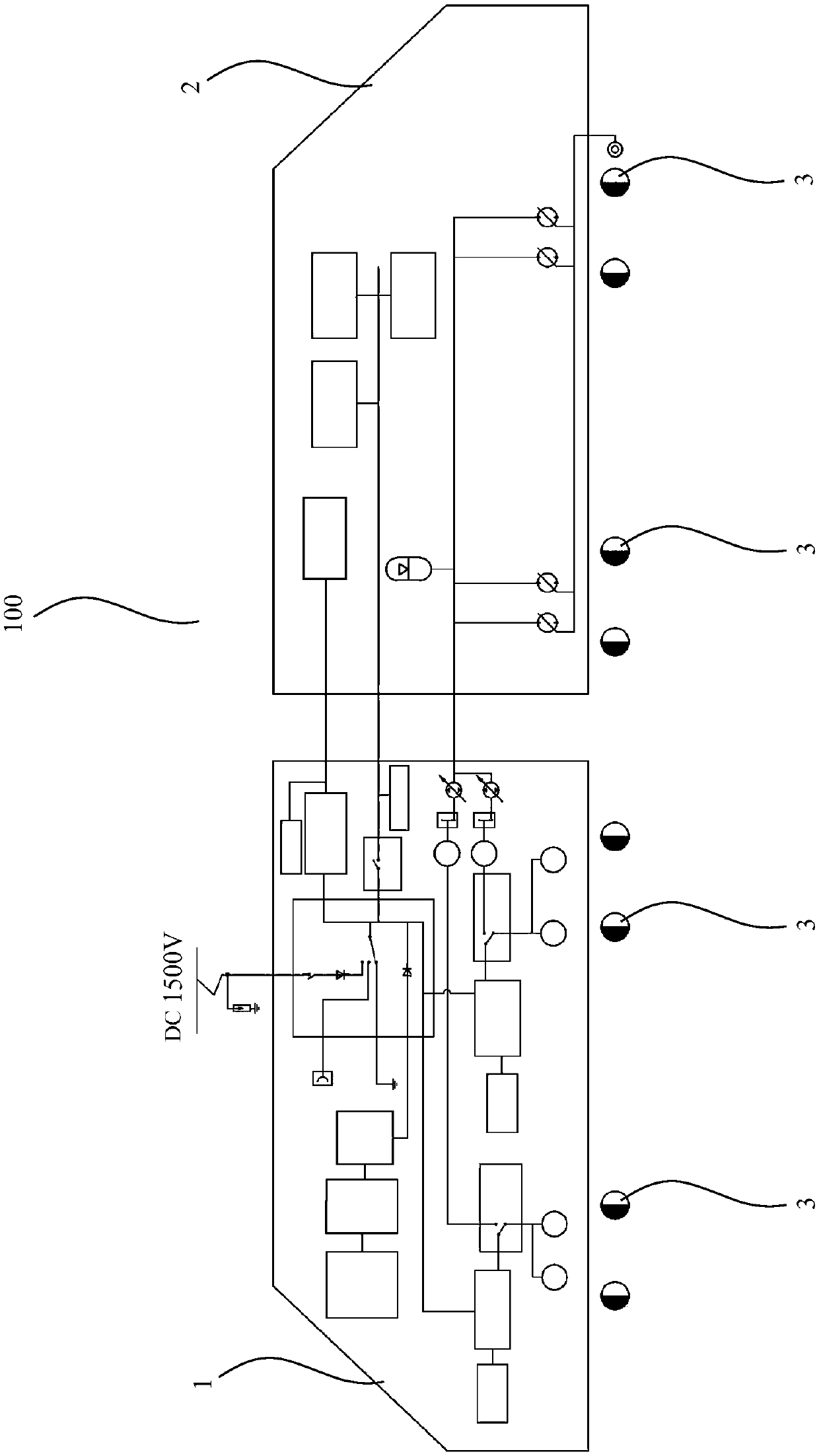

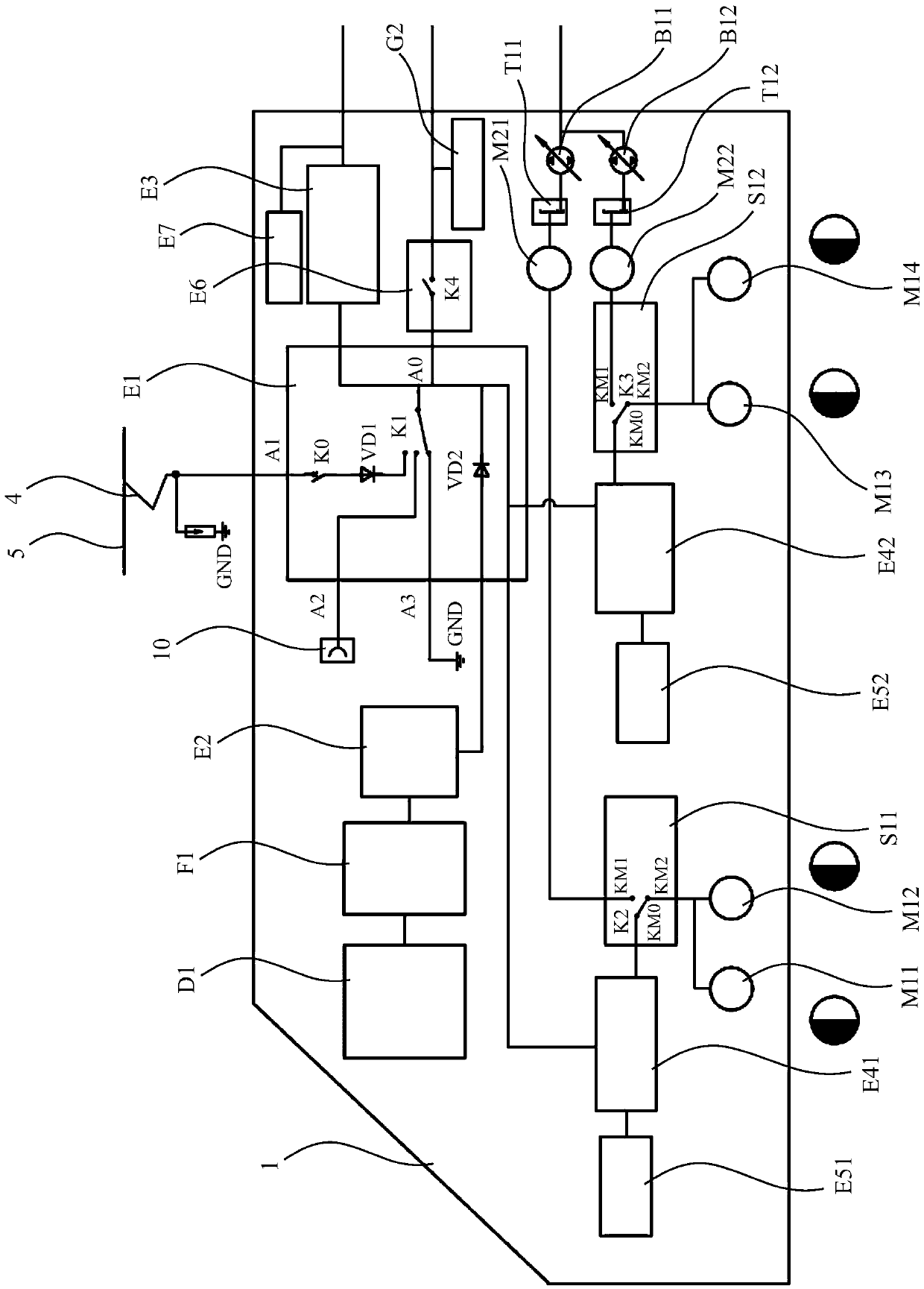

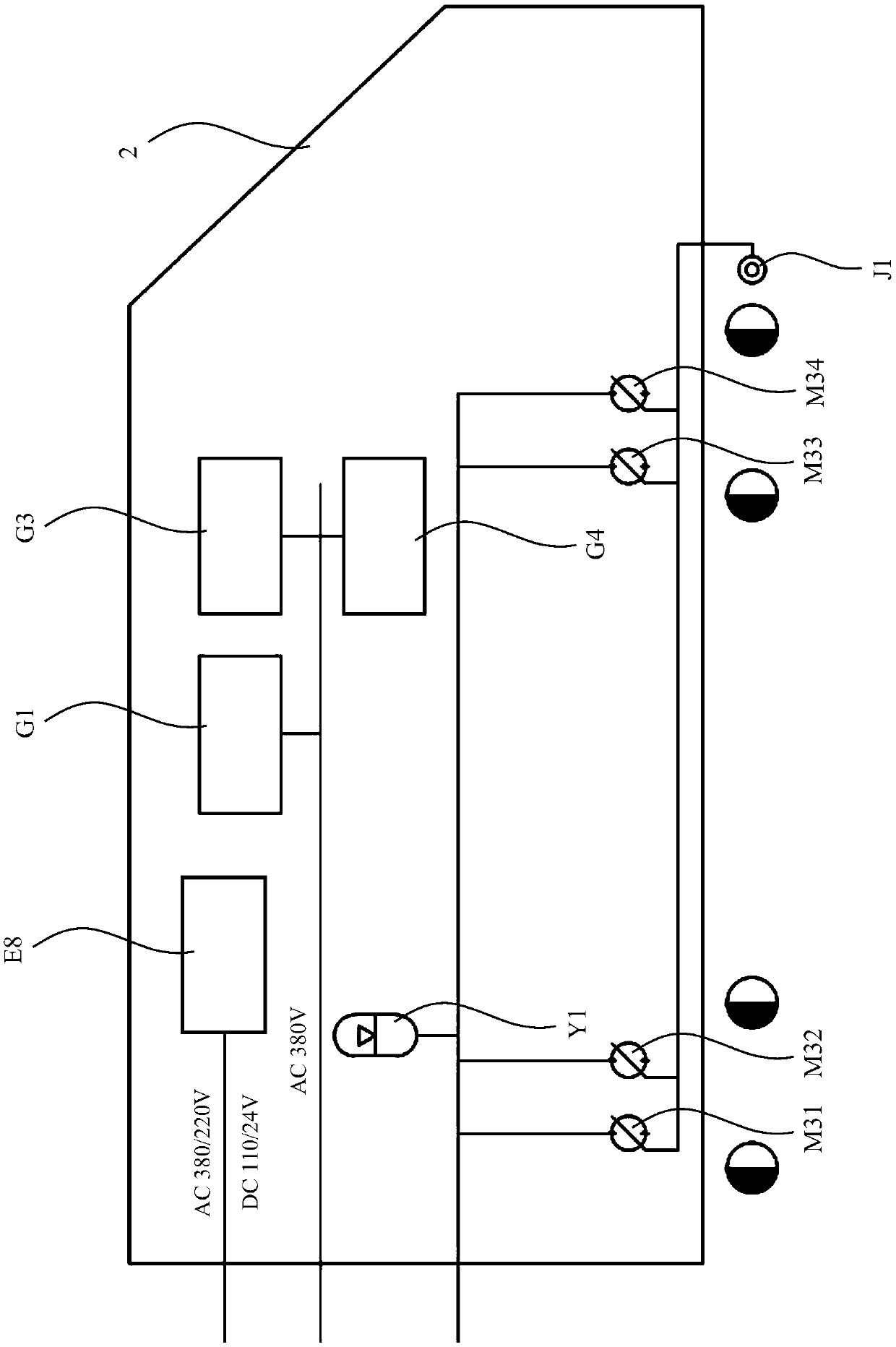

[0049] as attached figure 1 As shown, a kind of embodiment of the transmission system of the rail working vehicle based on the method of the present invention, the rail working vehicle 100 includes a power vehicle 1 and a working vehicle 2, and the transmission system specifically includes: a vehicle power supply system arranged on the power vehicle 1, The high-speed traveling system and the low-speed traveling power source, the low constant-speed traveling system arranged on the work vehicle 2, and the operating system partially or completely arranged on the work vehicle 2. The vehicle power supply system provides power for the operating system, and can optionally provide power for the high-speed traveling system or low-speed traveling power source. The high-speed traveling system adopts the electric drive traction system to realize the traveling speed of the rail operating vehicle at 0-80km / h. And the speed control accuracy is less than 0.5km / h. The low-speed running power ...

Embodiment 2

[0073] Another embodiment of the rail work vehicle transmission system based on the method of the present invention, the rail work vehicle 100 includes a power vehicle 1 and a work vehicle 2, and the transmission system specifically includes: a vehicle power supply system arranged on the power vehicle 1 and a high-speed running system, the low-speed constant-speed travel system and the low-speed travel power source arranged on the work vehicle 2, and part or all of the work system arranged on the work vehicle 2. The vehicle power supply system provides power for the operating system, and can optionally provide power for the high-speed traveling system or low-speed traveling power source. The high-speed traveling system adopts the electric drive traction system to realize the traveling speed of the rail operating vehicle at 0-80km / h. And the speed control accuracy is less than 0.5km / h. The low-speed running power source provides the hydraulic power source for the low-constant-s...

Embodiment 3

[0076] A rail working vehicle power transmission method of the present invention based on the system described in Embodiment 1, the rail working vehicle 100 includes a power vehicle 1 and a working vehicle 2, and the power transmission method includes the following steps:

[0077] A) Arrange the whole vehicle power supply system, high-speed running system and low-speed running power source on the power vehicle 1, and arrange the low-speed and constant-speed running system on the work vehicle 2; The operation system is arranged on the car 2;

[0078] B) The vehicle power supply system provides power for the operating system, and can optionally provide power for the high-speed traveling system or low-speed traveling power source. The high-speed traveling system adopts the electric drive traction system to realize the traveling of rail operating vehicles at 0-80km / h Speed, and speed control accuracy less than 0.5km / h;

[0079] C) The low-speed traveling power source provides the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com