High temperature resistant flexible conductive material based on PEAK and preparation method thereof

A conductive material, high temperature flexible technology, applied to the conductive layer on the insulating carrier, equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, etc., can solve problems such as difficult to withstand high temperature, achieve good electrical conductivity, Easy to achieve mass production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

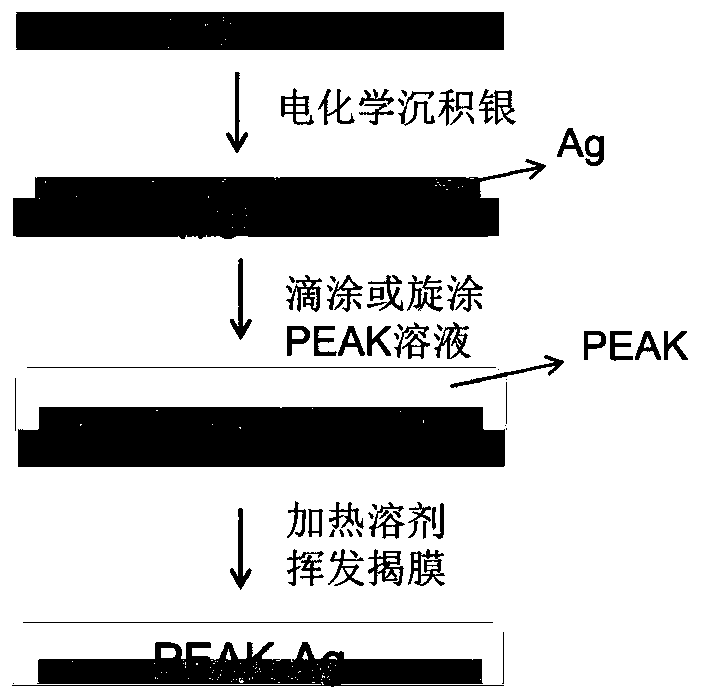

[0021] The ITO glass was ultrasonically cleaned with deionized water, acetone, and ethanol solution for 20 minutes, and then the ITO conductive surface was blown dry with nitrogen. Put the cleaned ITO glass in AgNO 3 and NaNO 3 The electrochemical deposition is carried out by chronoamperometry in the mixed solution, the reference electrode is a saturated mercurous sulfate electrode, the counter electrode is platinum wire, and the working electrode is ITO glass. The deposition time is 3200s, and the AgNO in the electrolyte mixed solution used 3 The concentration is 0.02mol / L, NaNO 3 The concentration is 0.09mol / L, and the potential set by electrochemical deposition is -0.45V. The resulting sample was called ITO-Ag-1.

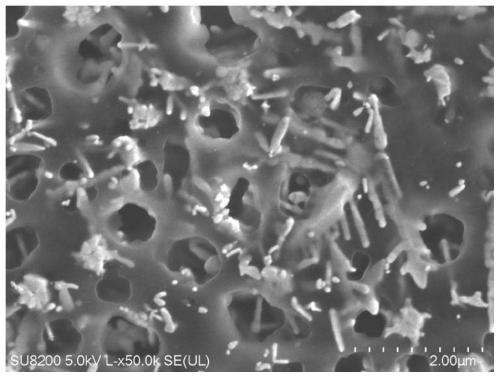

[0022] Place ITO-Ag-1 on a heating plate. A 10wt% PEAK polymer solution was prepared with NMP as a solvent, and the PEAK solution was uniformly drop-coated on the ITO-Ag-1. Set the temperature of the heating plate at 70°C and heat for 10 hours. After the so...

Embodiment 2

[0024] Example 2 PEAK-Ag high temperature performance test.

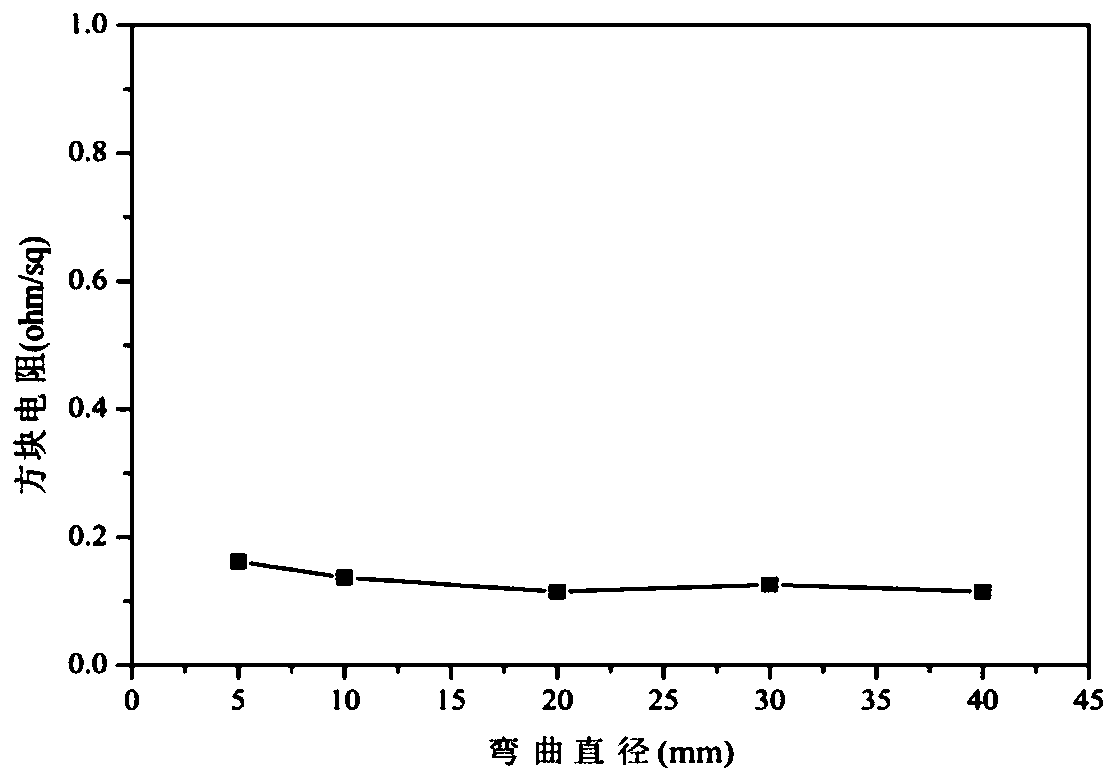

[0025] In order to characterize the high temperature resistance of the sample, the PEAK-Ag sample prepared by the aforementioned method was placed in a vacuum oven, the temperature was gradually raised, and it was stabilized for 10 minutes after rising to the set temperature. Sheet resistance is tested. The temperature has been raised from room temperature to 200°C to study the change law of the conductivity of the PEAK-Ag samples at different temperatures. like Figure 4 As shown, the sheet resistance of the sample has been kept at a low level from low temperature to high temperature, and the lowest can reach about 0.1 ohm, indicating that it has excellent electrical conductivity. When heated to about 200 degrees, although the resistance increases slightly, it still remains below 0.5 ohms, which fully proves that it has excellent heat resistance and still has good conductivity under high temperature conditions. ...

Embodiment 3

[0026] Example 3 PEAK-Ag hydrothermal oxidation resistance test.

[0027] In order to characterize the hydrothermal oxidation resistance of the sample, the PEAK-Ag sample prepared by the above method was placed in hot water at 90 °C, and the sample was taken out regularly to test its sheet resistance, and the change of the sheet resistance of the sample was studied as the heating time increased. The hydrothermal conditions can make the nano-silver conductive layer oxidize more violently, and the conductivity of most flexible conductive materials will decrease rapidly under hydrothermal conditions, and the sheet resistance will increase significantly. However by Figure 5 It can be seen that the sheet resistance of the PEAK-Ag sample prepared by the present invention hardly changes after being kept under hydrothermal conditions for 90 minutes, thus indicating that the sample has excellent hydrothermal oxidation resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com