Drying device for production of light-cleaning football stocks

A technology of drying device and football socks, which is applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problem of uneven drying in local areas, shorten the drying operation time, reduce the impact, and achieve a scientific and reasonable overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

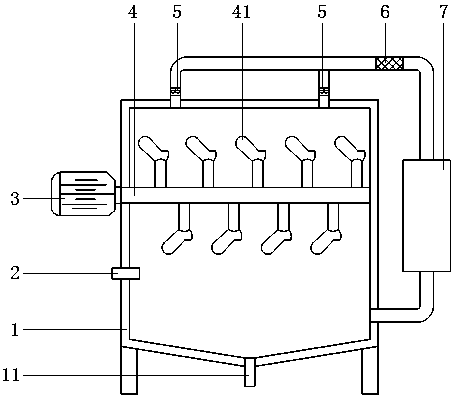

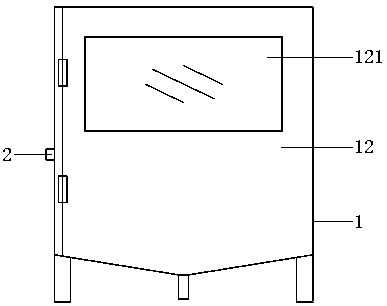

[0025] refer to Figure 1 ~ Figure 2 , the present invention is achieved in this way: a drying device for the production of light and clean football socks, which includes a box body 1 and a hot blast stove 7, and the top of the box body 1 is provided with several exhaust fans 5 and is connected to the hot blast stove 7 through a conveying pipeline. The input end is connected, and the output end of the hot blast stove 7 is connected to the lower end of one side of the box body 1 through the conveying pipeline; the shaft 4 arranged axially and horizontally is connected to the box body 1, and the shaft 4 is located in the box body 1 A number of stocking rods 41 are arranged on the inner and outer circular surfaces, and a drive motor 3 is provided on one side of the box body 1 and is connected with the rotating shaft 4. The bottom of the box body 1 is conical and the center of the bottom is provided with a drain 11. The conical structure is provided to facilitate the rapid dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com