Novel tubular preheater for carbon dioxide testbed and preheating method

A carbon dioxide and test bench technology, applied in indirect carbon dioxide emission reduction, combustion methods, lighting and heating equipment, etc., can solve the problem that the tube box equipment cannot realize the horizontal flow heat transfer of flue gas and air, and achieve perfect layout and simple manufacturing. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

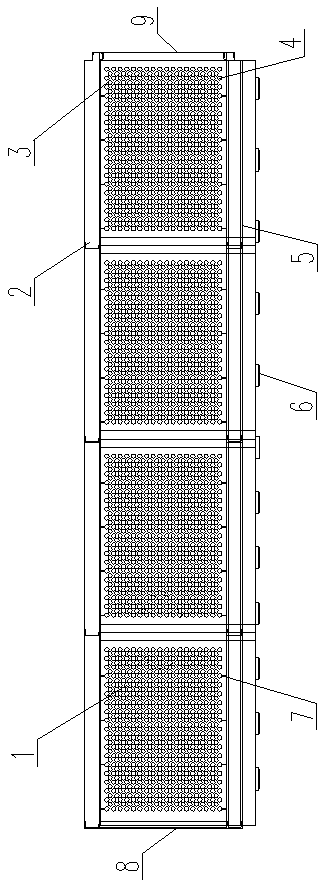

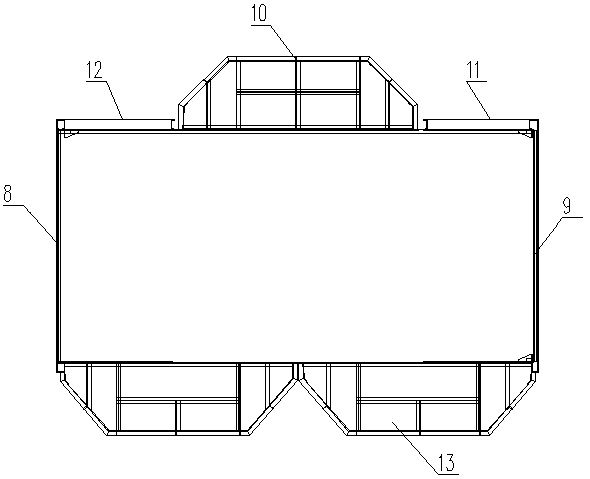

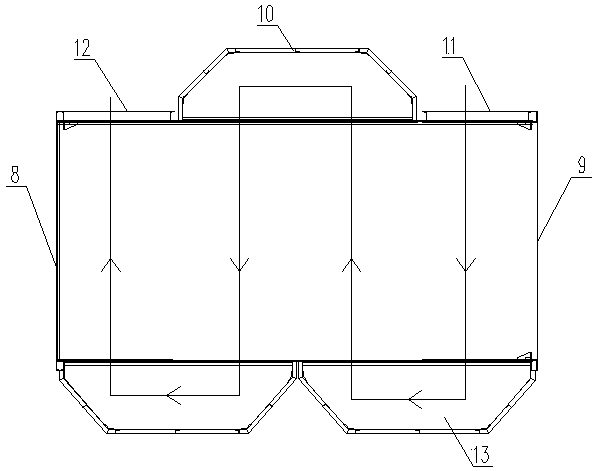

[0026] A new tubular preheater for a carbon dioxide test bench, which consists of: an intermediate tube bundle 1, the intermediate tube bundle includes two front and rear tube plates 3, and the tube plate has a set of horizontal round holes and vertical Installed on the sliding backing plate 6, pipes 4 are pierced in the horizontal circular holes between the front and rear two tube sheets, and a set of flat steel 7 is respectively fixed up and down the middle tube bundle, and above and below the tube sheets They are respectively fixed to the upper guard plate 2 and the lower guard plate 5, and the air duct communication box A10 is installed on one side of the middle tube bundle, and the air duct communication box B13 is installed on the other side.

Embodiment 2

[0028] According to the new tubular preheater for carbon dioxide test bench described in Example 1, the number of the intermediate tube bundles is one group, and the connection between them is welded between tube sheets, and the left end of the intermediate tube bundle is a smoke The air inlet 8, the right end is the flue gas outlet 9, the left side of the communication box A is the air duct outlet 12, and the right side is the air duct inlet 11.

Embodiment 3

[0030] According to the novel tubular preheater for a carbon dioxide test bench described in embodiment 1 or 2, the tube sheet is connected to the steel structure through the sliding backing plate, and the sliding backing plate includes an upper backing plate, The upper backing plate is connected with the lower backing plate through a slideway, and the lower backing plate is fixed with the steel structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com