Composite reinforced plastic floor and production process thereof

A technology of plastic flooring and production technology, which is applied in the direction of construction, building structure, floor, etc., can solve the problems of size change, high water expansion rate, floor deformation, etc., and achieve quality improvement, small wear resistance and scratch resistance, good The effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

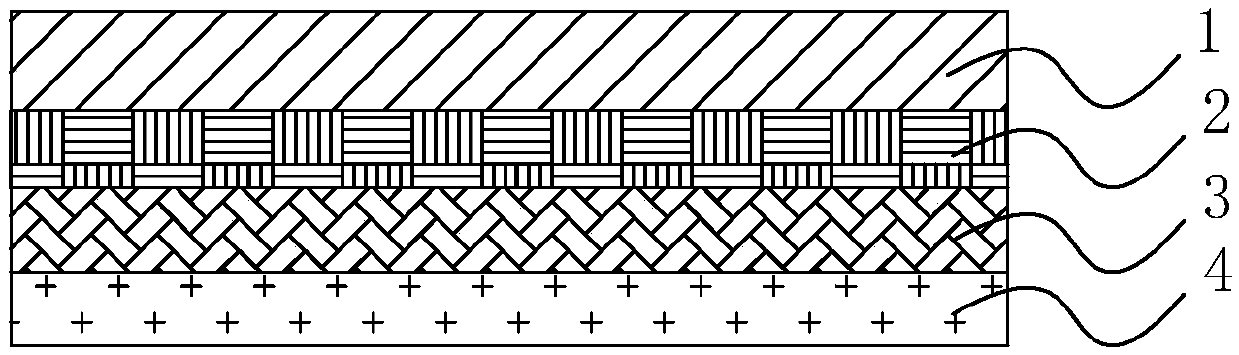

[0041] A kind of composite strengthened plastic floor, refer to figure 1 As shown, it includes wear-resistant layer 1, decorative layer 2, stone-plastic substrate layer 3 and balance layer 4 arranged in sequence from top to bottom. Hot pressing compound.

[0042] Wear-resistant layer 1, decorative layer 2, and balance layer 4 are all made of base paper. Base paper can be divided into surface paper, decorative paper and balance paper according to different functions. If you want to achieve decorative effects, use decorative paper; if you want To achieve the effect of wear resistance and scratch resistance, use surface paper; if you want to achieve the effect of mechanical balance, use balance paper. The wear-resistant layer 1 in this embodiment is made by impregnating melamine resin with the surface layer paper added with wear-resistant material Al2O3, which is a key part that determines the life of the floor, making the surface layer wear-resistant and scratch-resistant. The...

Embodiment 2

[0045] A composite reinforced plastic floor, the difference from Example 1 is that the stone-plastic substrate layer is composed of the following raw materials in parts by weight: 52 parts of polyvinyl chloride, 157 parts of stone powder, 6.2 parts of calcium zinc stabilizer, stearic acid 0.44 part, 5.5 parts of PVC modifier, 0.23 part of carbon black, 0.62 part of polyethylene wax, wherein PVC modifier is the acrylic resin of main body with methyl methacrylate.

Embodiment 3

[0047]A composite reinforced plastic floor, the difference from Example 1 is that the stone-plastic substrate layer is composed of the following raw materials in parts by weight: 57 parts of polyvinyl chloride, 163 parts of stone powder, 6.2 parts of calcium zinc stabilizer, stearic acid 0.44 part, 5.5 parts of PVC modifier, 0.23 part of carbon black, 0.62 part of polyethylene wax, wherein PVC modifier is the acrylic resin of main body with methyl methacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com