Cleaning device for fine hair processing

A cleaning device and fluff technology, applied in the direction of animal loose hair fiber washing/scouring, etc., can solve the problems of reduced processing efficiency, single fluff cleaning equipment, long waiting time for the beating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

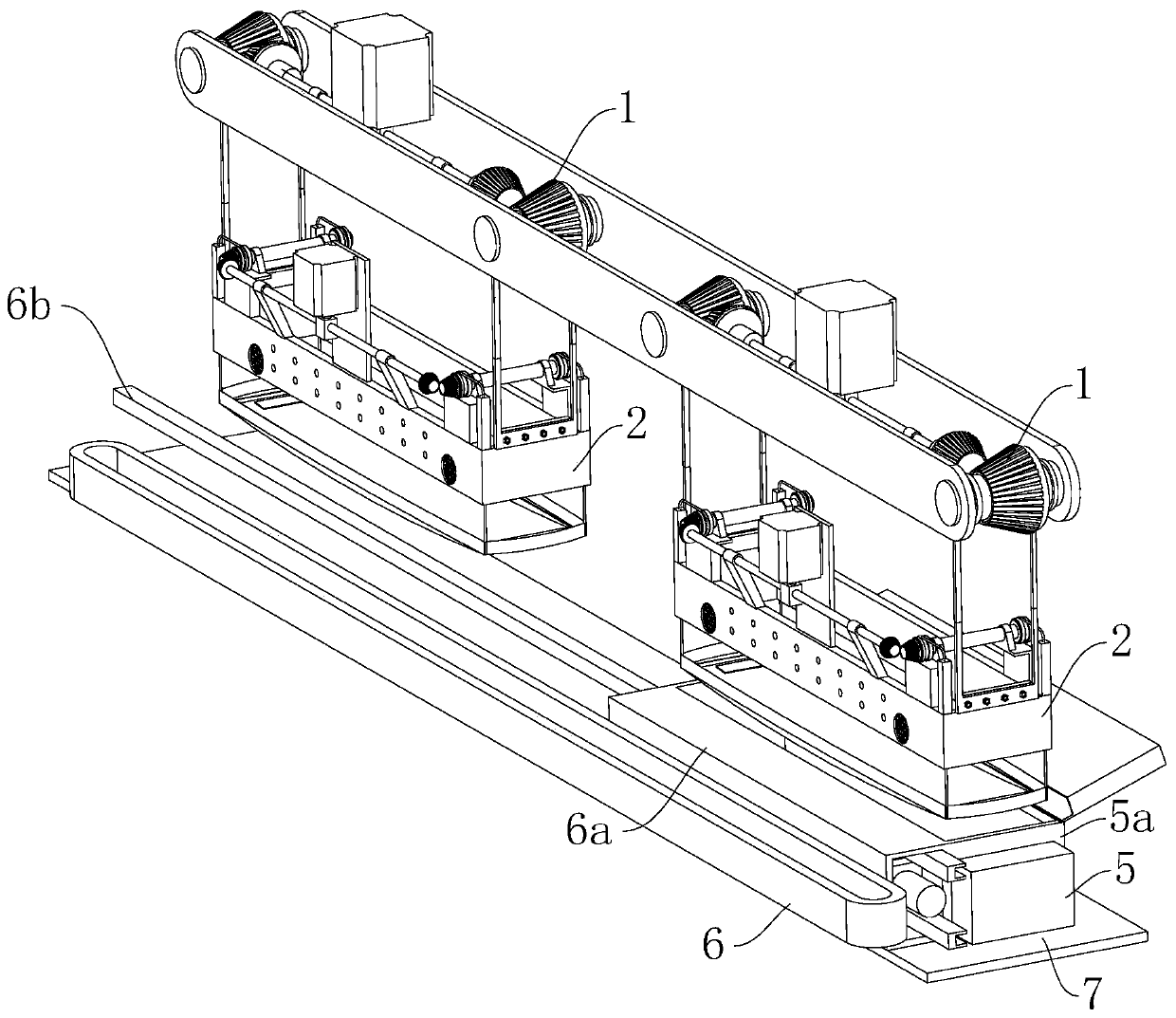

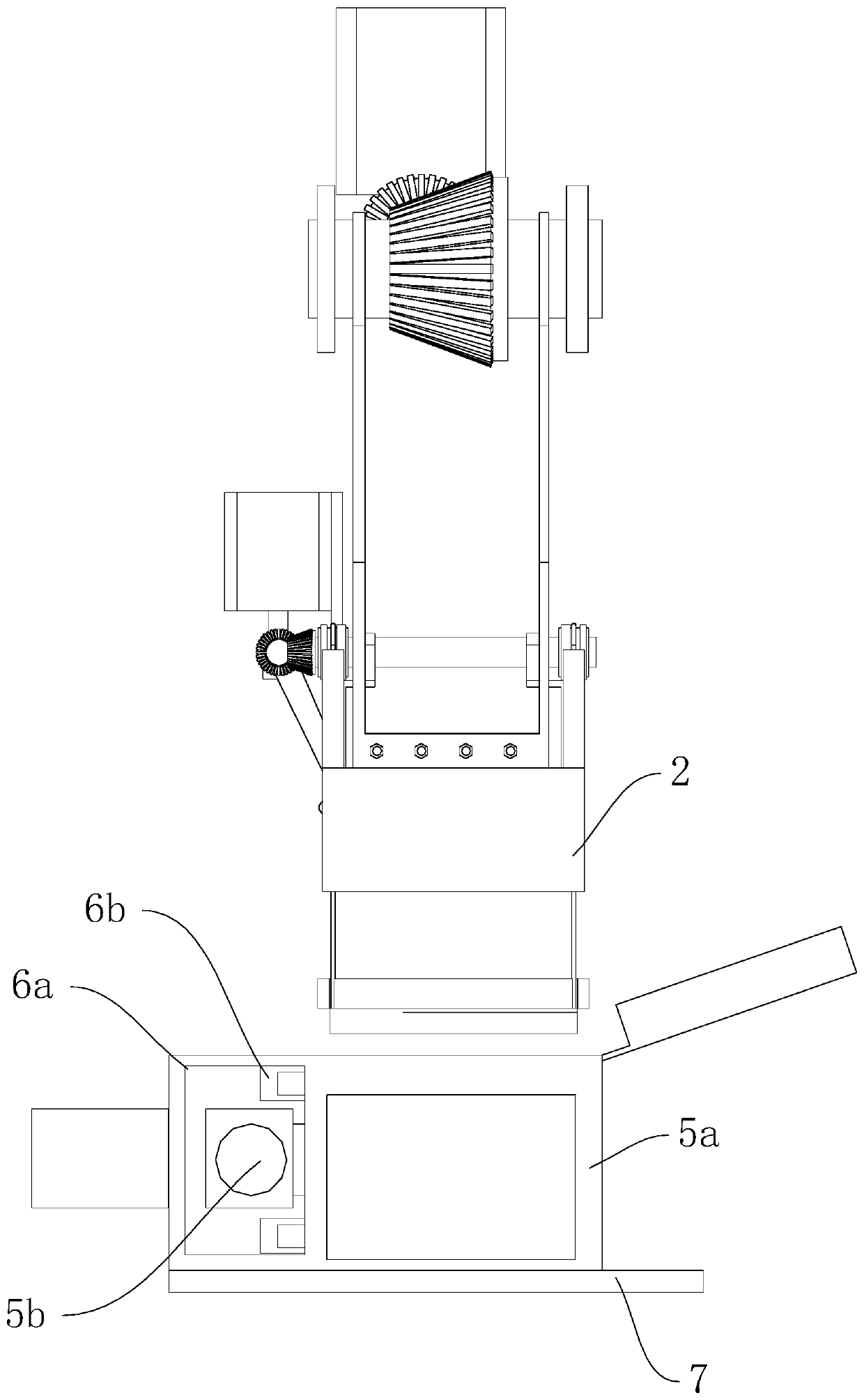

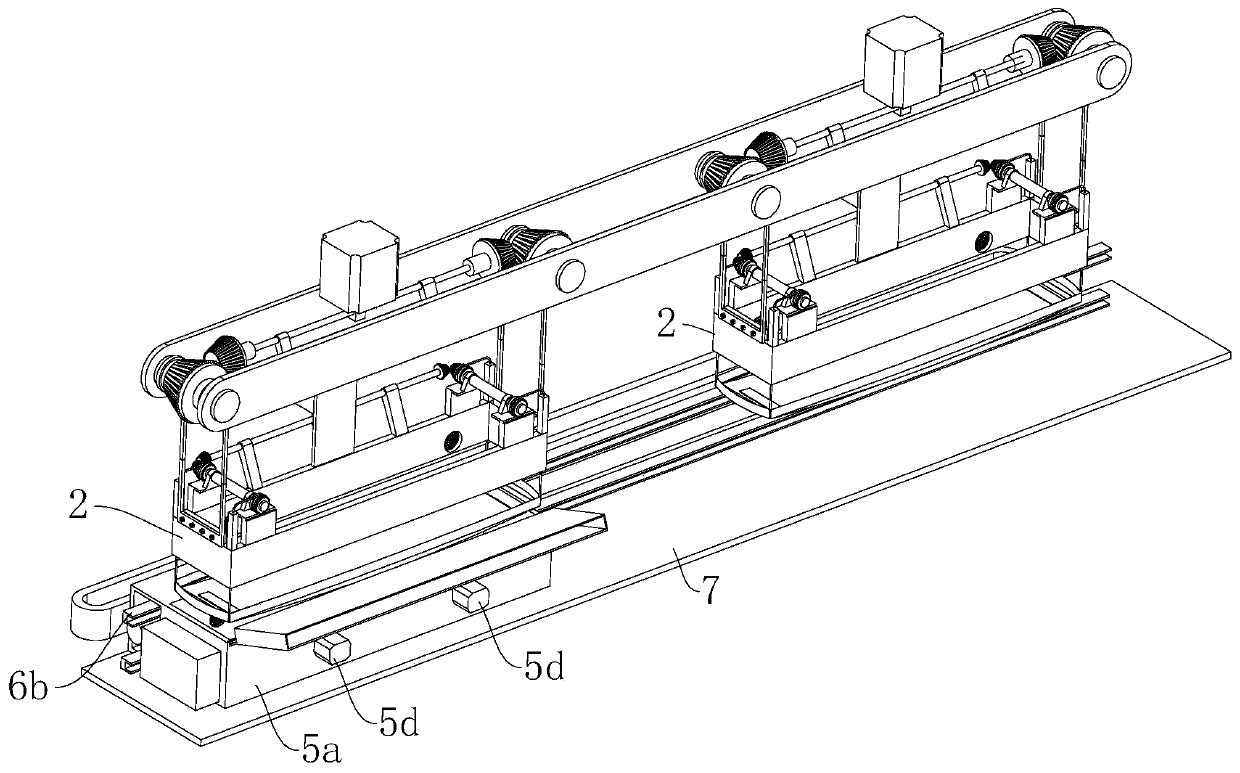

[0034] refer to Figure 1 to Figure 11 The shown cleaning device for fluff processing includes a controller, a cleaning mechanism and two storage mechanisms symmetrically arranged above the cleaning mechanism, each storage mechanism can be vertically movable through a lifting mechanism 1, and the cleaning mechanism Including an ultrasonic generator 5, a stainless steel cleaning chamber 5a and a composite transducer 5d, the composite transducer 5d is installed on the outer wall of the stainless steel cleaning chamber 5a, the ultrasonic generator 5 is electrically connected with the composite transducer 5d, and the stainless steel cleaning chamber 5a The front side is provided with a chain conveyor belt 6 connected to it, and the stainless steel cleaning bin 5a is driven by the chain conveyor belt 6 to make it travel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com