Floating ball type fresh food logistics transportation box

A transport box and float-type technology, applied in the field of float-type fresh food logistics transport boxes, can solve the problems of small fresh food activity space, insufficient oxygen content, vehicle body ground pollution, etc., to prevent water leakage and achieve better results , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

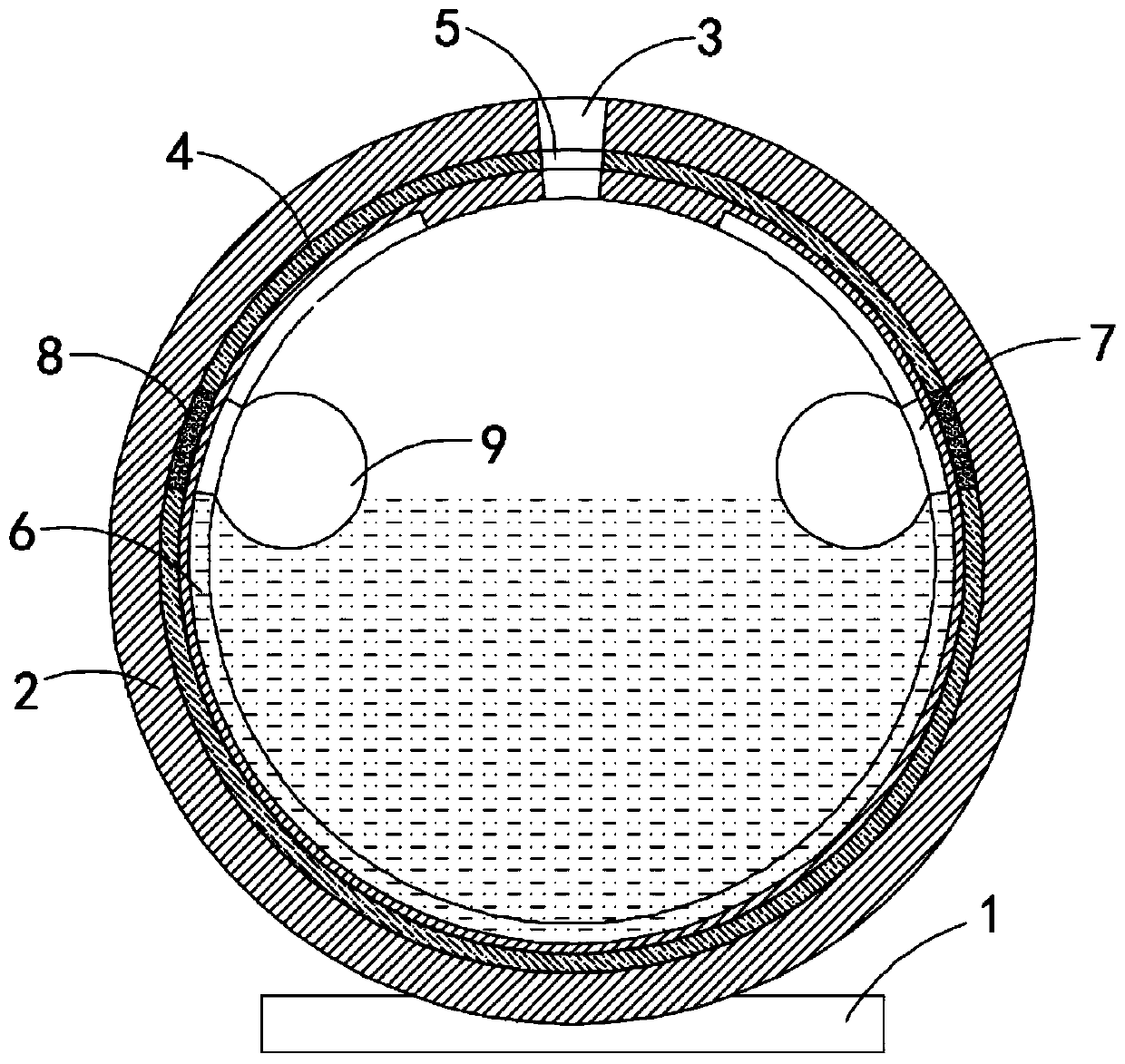

[0026] Such as Figure 1-3 As shown, a floating ball type fresh logistics transportation box includes a base 1, the upper end of the base 1 is fixedly connected with a housing 2, the housing 2 is a cylinder placed horizontally, and the upper end of the housing 2 is provided with a strip-shaped air vent 3 (such as image 3 As shown), the housing 2 is provided with an annular inner sliding groove, the inner sliding groove is rotationally connected with an inner sealing ring 4, and the inner sealing ring 4 is provided with an inner strip-shaped opening 5 corresponding to the strip-shaped air vent 3, The inner side wall of the housing 2 is provided with an arc-shaped chute 6, and both sides of the arc-shaped chute 6 are slidably connected with a slider 7, the slider 7 is made of ferromagnetic material, and the inner sealing ring 4 is embedded with a The permanent magnet segment 8 that the slider 7 attracts to each other, a floating ball 9 is installed on the side wall of the slid...

Embodiment 2

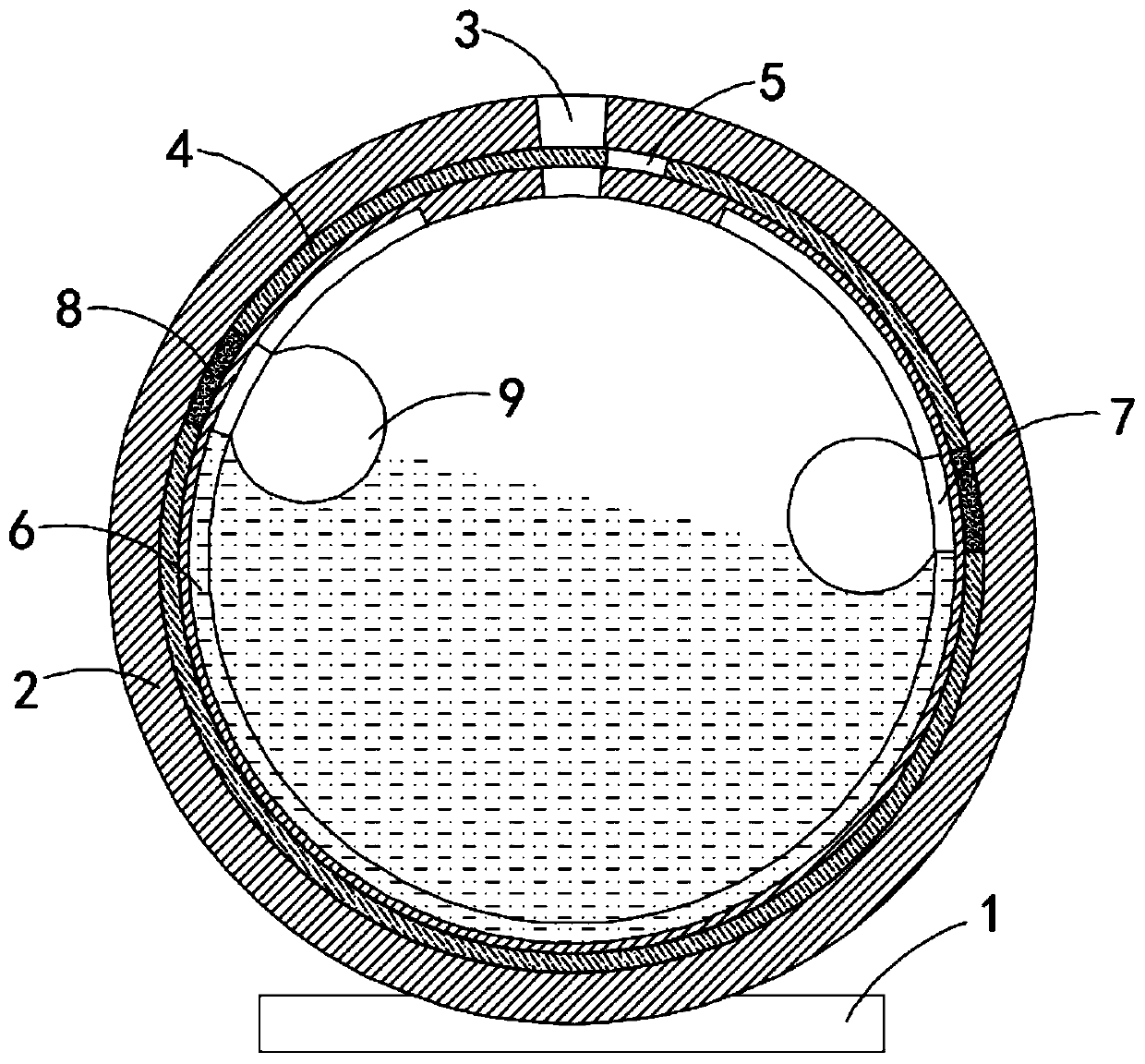

[0029] Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that L-shaped connecting rods 10 are fixedly connected to both sides of the side wall of the slider 7, and threaded rods 11 are fixedly connected between the two L-shaped connecting rods 10. Specifically, the threaded rod 11 is a fine thread, and the floating ball 9 is rotatably set on the threaded rod 11, and the floating ball 9 is provided with a threaded groove matching the threaded rod 11. It is worth mentioning that the floating ball 9 Made of rigid polyurethane foam.

[0030] Due to the difference in fresh food transportation volume or variety, the water storage capacity in the housing is also different. In the process of using this embodiment, the position of the floating ball 9 can be adjusted according to the amount of water, that is, the height of the liquid level. It should be noted that the positions of the two floating balls 9 should be kept at the same height. It shou...

Embodiment 3

[0032] Such as Figure 6-7 As shown, the difference between this embodiment and Embodiment 2 is that: the housing 2 is provided with an annular outer sliding groove, and an outer sealing ring 12 is slidably connected to the outer sliding groove, and the outer sealing ring 12 is provided with a bar-shaped The outer strip-shaped opening 13 corresponding to the air vent 3 has a communication port between the inner sliding groove and the outer sliding groove, and a gear 14 is rotatably connected in the communication port, and the outer side wall of the inner sealing ring 4 and the inner side wall of the outer sealing ring 12 All are provided with tooth grooves meshed with the gear 14.

[0033] In this embodiment, by setting the inner seal ring 4 and the outer seal ring 12, and the two are connected through the transmission of the gear 14, when the inner seal ring 4 rotates, the outer seal ring 12 will move in the opposite direction under the action of the gear 14 Rotate to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com