Repair method of transmission chain

A transmission chain, a pair of technology, applied in the direction of metal chains, etc., can solve the problems of waste, short chain length, exceeding the length range, etc., to achieve the effect of simple steps and fast maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

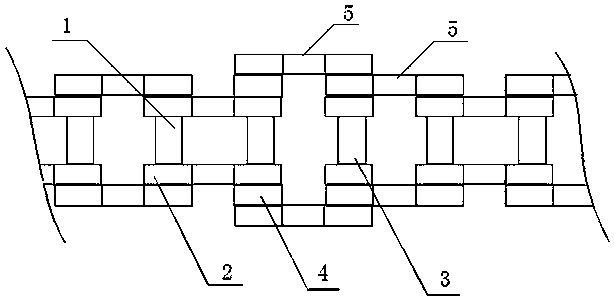

[0013] Such as figure 1 As shown, a method for repairing a transmission chain includes:

[0014] 1. Take off one inner chain link 1 and the outer chain plate 5 connected to it;

[0015] 2. Cut the removed inner chain link 1 along the middle of the inner chain plate 2 and polish it into a circular cylinder 3. The radius of the circular cylinder 3 is the radius of the outer circumference of the chain plate;

[0016] 3. Remove the two half of the inner chain plate 2 on the remaining inner chain link in step 2 from the sleeve and grind them into two circular rings 4. The radius of the circular ring 4 is the outer circumference of the chain plate. Radius of

[0017] 4. Insert the circular cylinder 3 between the suspended pair of chain plates 5, install the two circular rings 4 on the two ends of the exposed inner link 1, and then use the removed pair of chain plates 5. Fix it with pins from both sides to connect the chain.

[0018] When there are no accessories, the method can quickly rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com