Method of coating a building panel with digital printing/coating technique

A technology of architectural paneling, digital printing, applied in the direction of post-processing of printing, duplication/marking methods, coatings, etc., which can solve the problems that cannot be used to provide part of the final decoration or surface structure, etc., to achieve strong wear resistance, Strong impact resistance, beautifully designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

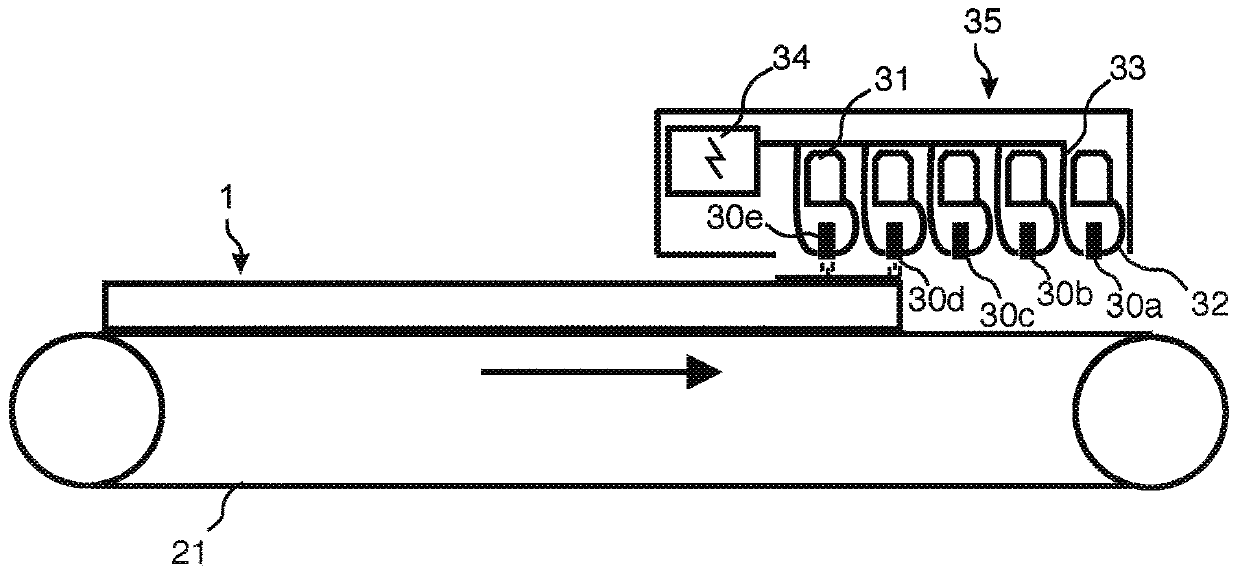

[0163] Digital images are applied to the panels comprising high density fiber (HDF) boards. Images were generated using a single-pass printer comprising 5 stationary piezoelectric print heads. The inks are water-based inks containing colored pigments.

[0164] A piezoelectric print head with a drop size of 50 picoliters was used to apply a water-based UV-cured polyurethane clear layer equivalent to 10 g / m 2 film. The above materials are cured in a UV oven and a digital image with a digitally applied transparent layer can be obtained.

example 2

[0166] A digital image with a wood grain design was applied to the paneling comprising HDF boards. The image was generated using a single-pass printer comprising 5 stationary piezoelectric print heads. The inks used are water-based inks containing colored pigments.

[0167] A piezoelectric print head with a drop size of 50 picoliters was used to apply a water-based UV-cured polyurethane clear layer equivalent to 10 g / m 2 film. The above materials are cured in a UV oven.

[0168] Weight is 5g / m 2 Another similar transparent layer was applied using a piezoelectric print head with a droplet size of 50 μl. This layer is applied as a transparent image that coordinates with the digital image.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com