Vanadium-doped cobalt-iron layered double hydroxide/foamed nickel nano composite material and preparation method thereof

A nanocomposite material and hydroxide technology, applied in the field of vanadium-doped cobalt-iron layered double hydroxide/foamed nickel nanocomposite material and its preparation, can solve the problem of unstable catalytic performance, limited large-scale application, earth To solve problems such as scarcity of resources, the experimental conditions are mild and controllable, the practicability is strong, and the raw materials are abundant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.2402g of ferric chloride hexahydrate, 0.2114g of cobalt trichloride hexahydrate and 0.0349g of vanadium trichloride and 0.2g of urea into the beaker, then add 40mL of deionized water, and then put the beaker Put it on a magnetic stirrer and stir evenly at a speed of 400 rpm for 15 minutes to ensure that the salts are fully dissolved. Then move the solution to a 50mL reactor, put 2 pieces of nickel foam that have been cut and pretreated vertically along the wall, then put the reactor into an oven, and react at a temperature of 120°C for 20h. After the reaction kettle is completely cooled, the nickel foam is taken out and washed three times with deionized water and ethanol respectively, and finally the nickel foam is dried in a vacuum oven at 60°C for 10 hours and taken out to obtain vanadium-doped cobalt-iron layered double hydroxide matter / nickel foam nanocomposites.

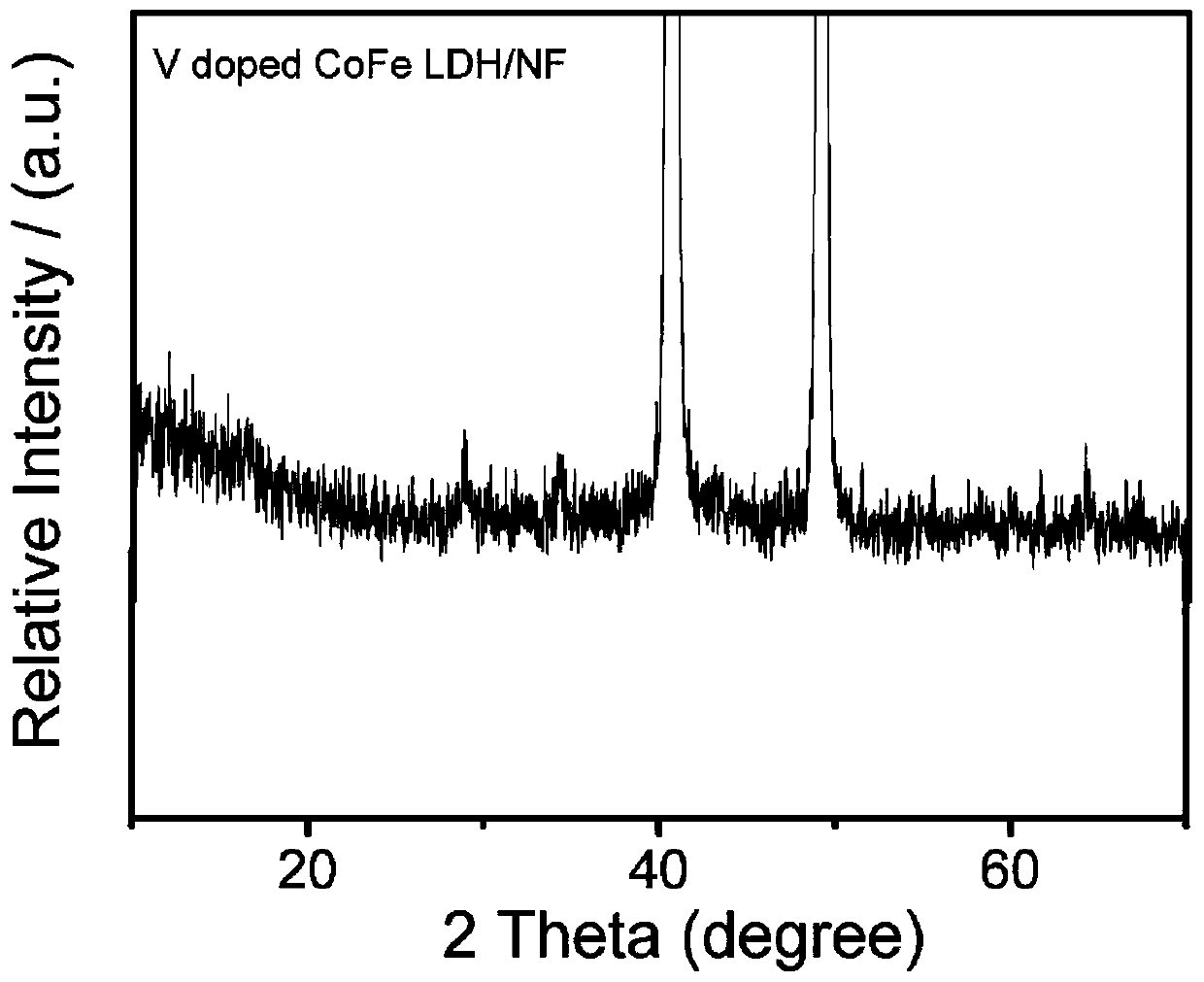

[0026] figure 1 The phase structure of the material can be obtained, and the two strong peak...

Embodiment 2

[0030] Weigh 0.1802g of ferric chloride hexahydrate, 0.2379g of cobalt trichloride hexahydrate and 0.0524g of vanadium trichloride and 0.2g of urea into the beaker, then add 40ml of deionized water, and then put the beaker Put it on a magnetic stirrer and stir evenly at a speed of 400 rpm for 15 minutes to ensure that the salts are fully dissolved. Then move the solution to a 50mL reactor, put 2 pieces of nickel foam that have been cut and pretreated vertically along the wall, then put the reactor into an oven, and react at a temperature of 120°C for 20h. After the reaction kettle is completely cooled, the nickel foam is taken out and washed three times with deionized water and ethanol respectively, and finally the nickel foam is dried in a vacuum oven at 60°C for 10 hours and taken out to obtain vanadium-doped cobalt-iron layered double hydroxide matter / nickel foam nanocomposites.

Embodiment 3

[0032] Weigh 0.1802g of ferric chloride hexahydrate, 0.1586g of cobalt trichloride hexahydrate and 0.1048g of vanadium trichloride and 0.2g of urea into the beaker, then add 40ml of deionized water, and then put the beaker Put it on a magnetic stirrer and stir evenly at a speed of 400 rpm for 15 minutes to ensure that the salts are fully dissolved. Then move the solution to a 50mL reactor, put 2 pieces of nickel foam that have been cut and pretreated vertically along the wall, then put the reactor into an oven, and react at a temperature of 120°C for 20h. After the reaction kettle is completely cooled, the nickel foam is taken out and washed three times with deionized water and ethanol respectively, and finally the nickel foam is dried in a vacuum oven at 60°C for 10 hours and taken out to obtain vanadium-doped cobalt-iron layered double hydroxide matter / nickel foam nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com