One-step preparation of superhydrophilic/underwater superoleophobic oil-water separation mesh and method

A super-oleophobic oil and super-hydrophilic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of inability to prepare super-hydrophilic/underwater super-oleophobic oil-water separation omentum, and achieve production Low cost, reduced usage, design science effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

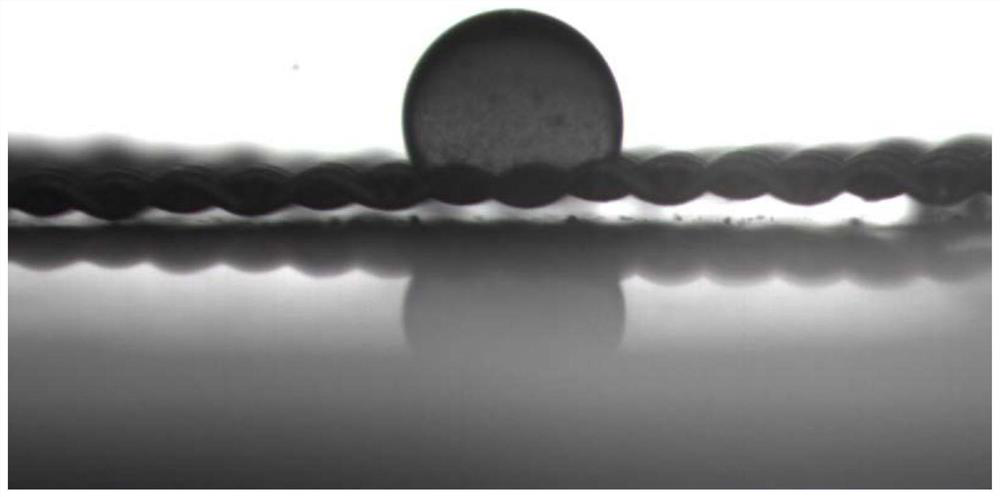

[0035] This embodiment discloses a method for preparing a superhydrophilic / underwater superoleophobic oil-water separation omentum by one-step method of the present invention, specifically:

[0036] Step 1. Pretreatment of cathode and anode materials: two pieces of stainless steel wire mesh of the same size are ultrasonically cleaned with absolute ethanol and a large amount of distilled water to remove surface organic matter, residual liquid and other impurities, and then dried in a 60°C drying oven for later use , the aperture of the stainless steel wire mesh is 80 mesh;

[0037] Step 2. Preparation of electroplating solution: take a certain amount of nickel sulfate, add distilled water to dissolve, and prepare a nickel-containing solution with a concentration of 0.5mol / L, then adjust the pH of the solution to 10 with ammonia;

[0038] Step 3. Preparation of the metal mesh coating base: Insert the two pieces of metal mesh treated in step 1 into the double-electrode electrolyt...

Embodiment 2

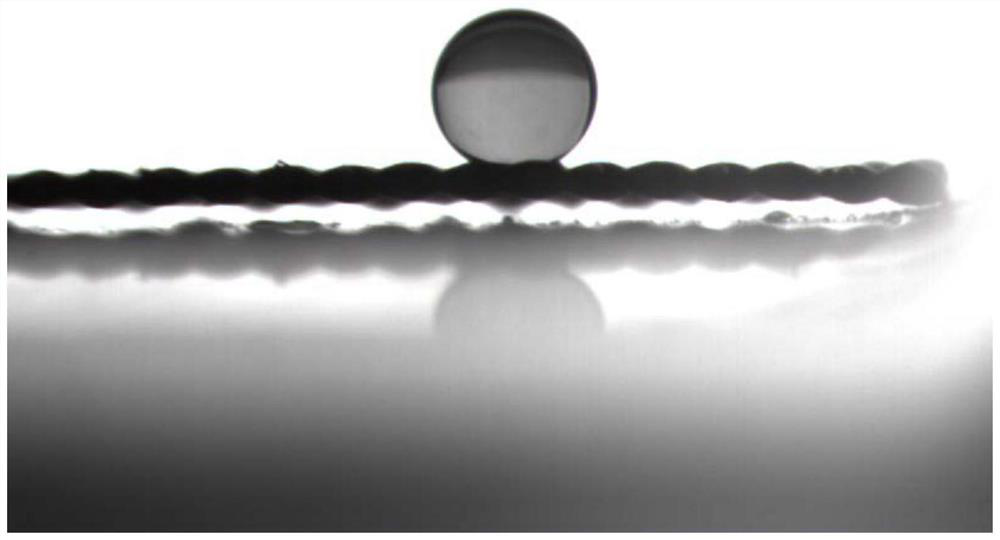

[0043] This embodiment discloses a method for preparing a superhydrophilic / underwater superoleophobic oil-water separation omentum by one-step method of the present invention, specifically:

[0044]Step 1. Pretreatment of cathode and anode materials: two pieces of titanium mesh with the same size and 200-mesh pore size are ultrasonically cleaned with absolute ethanol and a large amount of distilled water to remove surface organic matter, residual liquid and other impurities. Dried in a drying oven for later use;

[0045] Step 2. preparation of electroplating solution: take a certain amount of nickel nitrate, add distilled water to dissolve, be mixed with a concentration of 0.8mol / L nickel-containing solution, then adjust the pH of the solution to 8 with ammonia;

[0046] Step 3. Preparation of the metal mesh coating base: Insert the two pieces of metal mesh treated in step 1 into the double-electrode electrolytic cell, and make the cathode and anode respectively, and add the e...

Embodiment 3

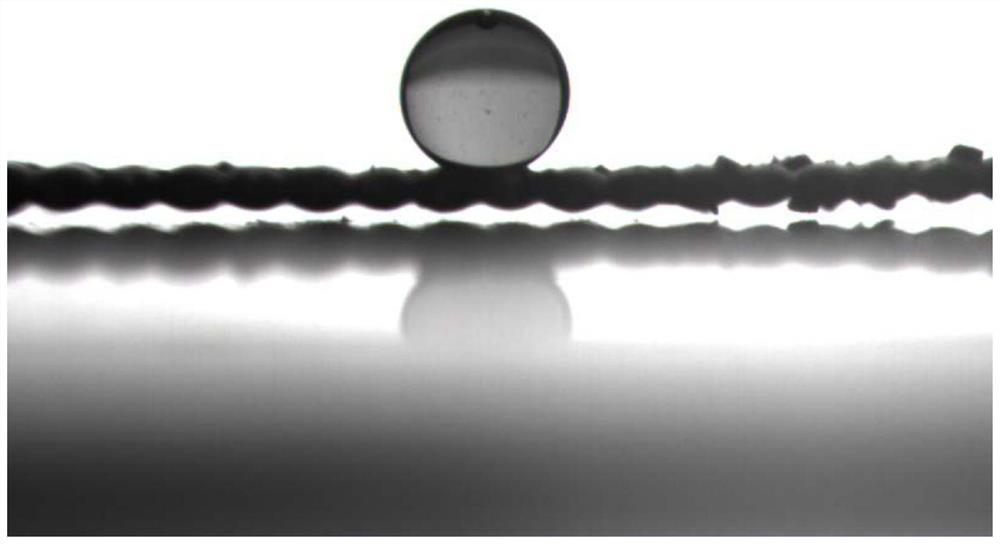

[0049] This embodiment discloses a method for preparing a superhydrophilic / underwater superoleophobic oil-water separation omentum by one-step method of the present invention, specifically:

[0050] Step 1. Pretreatment of cathode and anode materials: Clean two pieces of copper wire mesh with the same size and 80-mesh aperture with absolute ethanol and a large amount of distilled water in order to remove the surface organic matter, residual liquid and other impurities. Dried in a drying oven for later use;

[0051] Step 2. Preparation of electroplating solution: take a certain amount of nickel chloride, add distilled water to dissolve, and prepare a nickel-containing solution with a concentration of 0.1mol / L, then adjust the pH of the solution to 12 with ammonia;

[0052] Step 3. Preparation of the metal mesh coating base: Insert the two pieces of metal mesh treated in step 1 into the double-electrode electrolytic cell, and make the cathode and anode respectively, and add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com