Cleaning head for ground cleaning equipment

A floor cleaning and cleaning head technology, applied in the field of cleaning equipment, can solve the problems of motor damage, wetting the outside of the box, and leakage, etc., to achieve the effect of keeping clean and improving wetting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

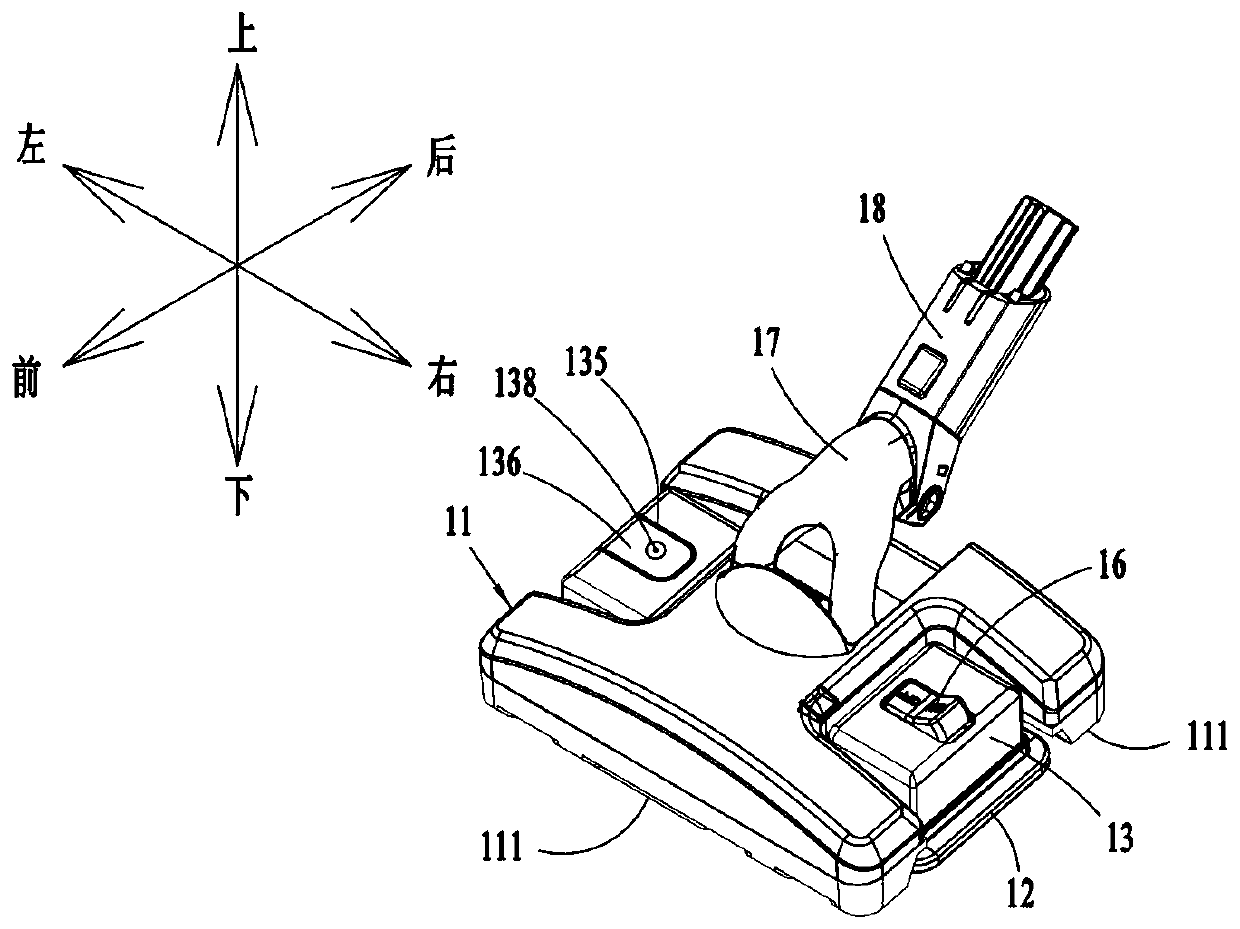

[0045] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings. Wherein, the upper, lower, left, right, front and rear positional relationships described in this embodiment are related to figure 1 The respective positional relationships shown in correspond to each other.

[0046] The cleaning head of the present invention is mainly used in floor cleaning equipment, which is equipment for vacuuming and / or cleaning the ground to be cleaned, for example, it can be a wet and dry vacuum cleaner, or a floor washing machine .

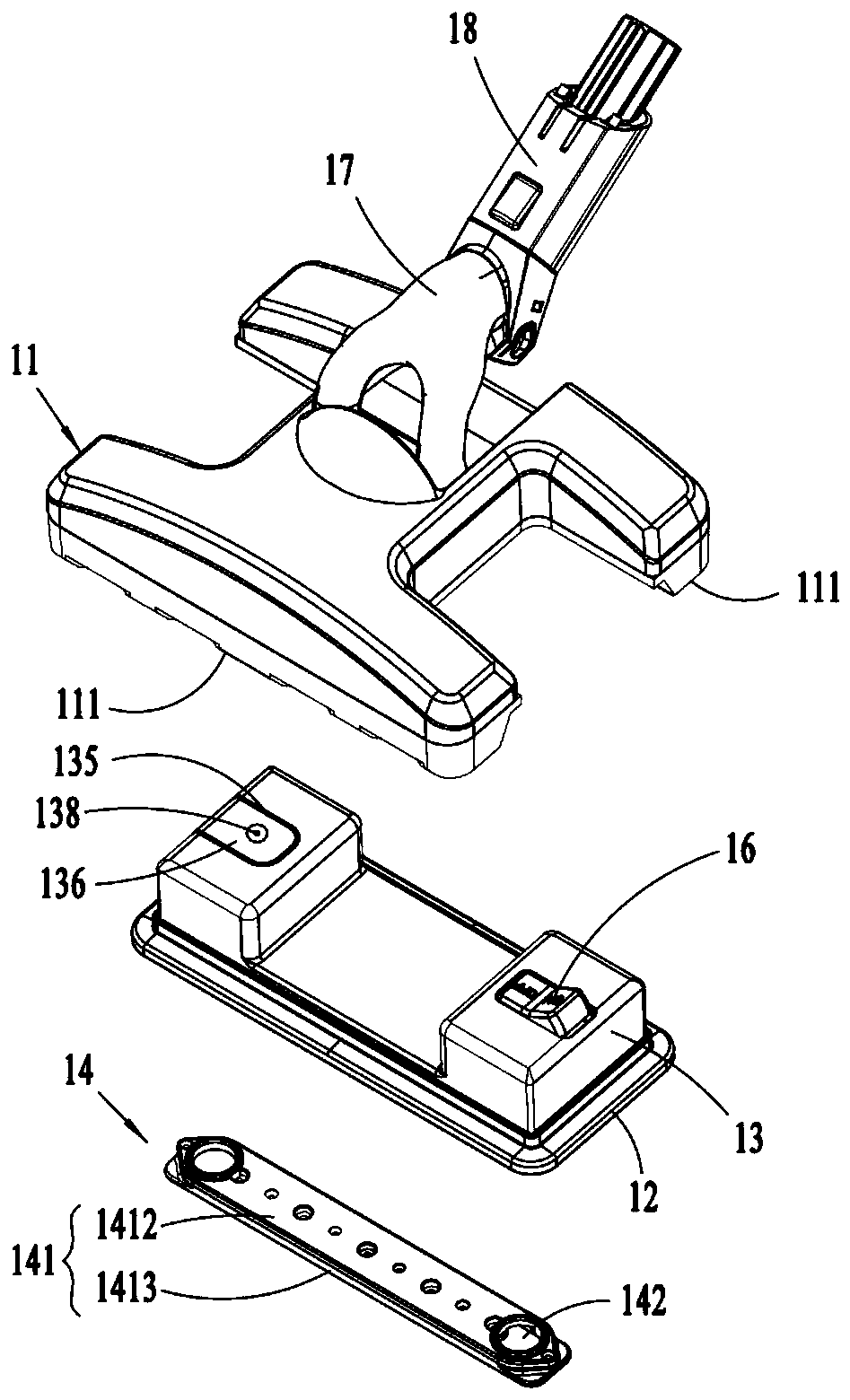

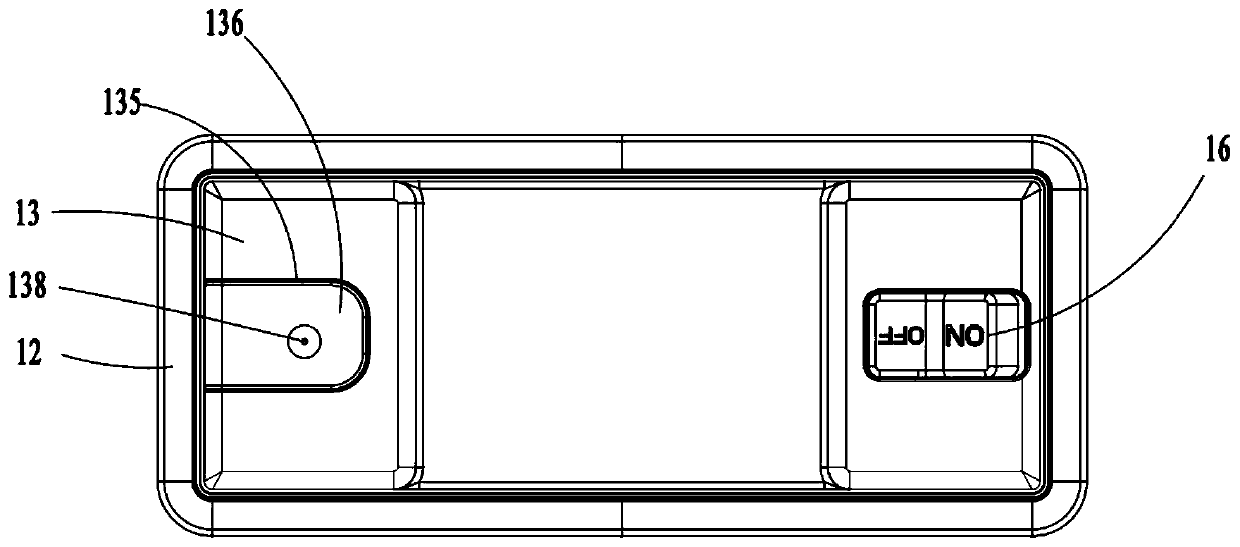

[0047] Such as Figure 1-Figure 2 As shown, the cleaning head includes a cleaning head body 11 , a bottom plate 12 , a water supply tank 13 , a water distributor 14 , a rotary joint 17 and a suction channel 18 .

[0048] Wherein, the rotating connection head 17 is connected to the cleaning head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com