Total power fuel cell air compressor dual-layer prediction control method

A fuel cell and predictive control technology, applied in fuel cells, computer control, program control, etc., can solve the problems of fuel cell net power reduction and power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

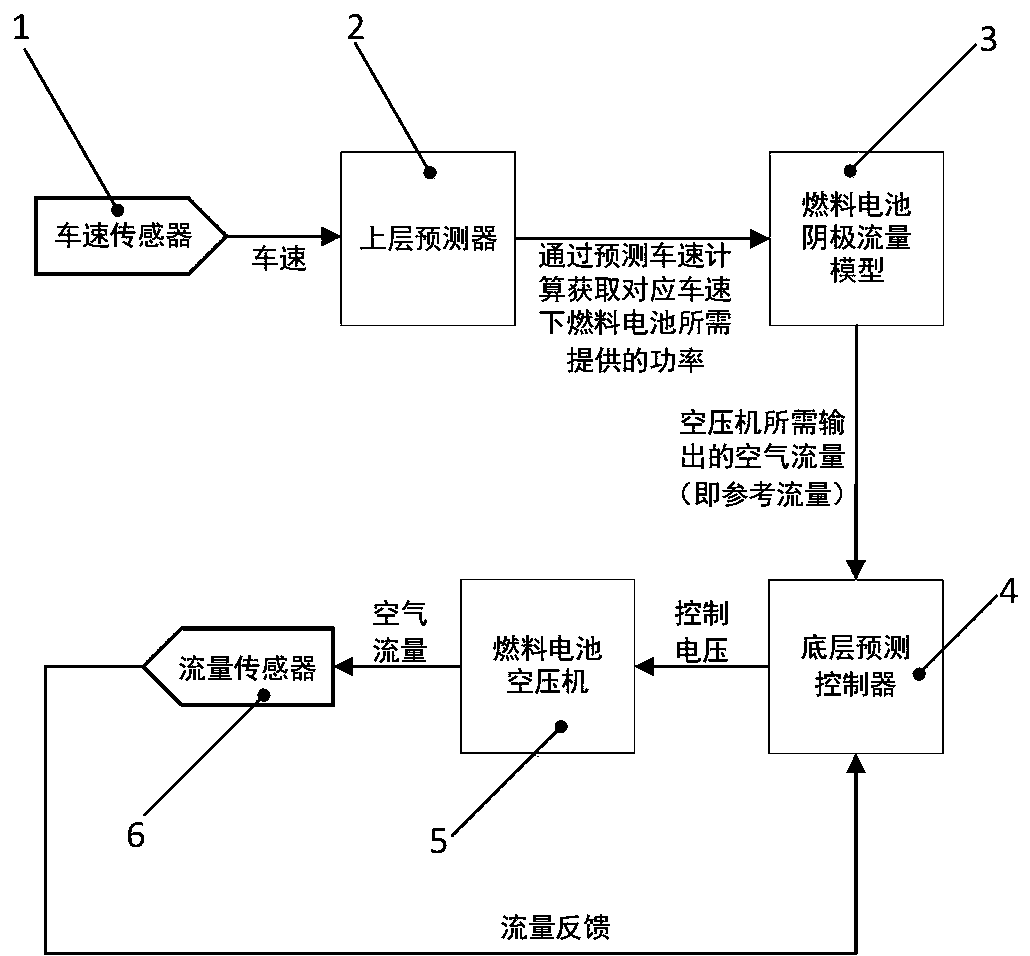

[0069] Please refer to figure 1 , the present invention provides a double-layer predictive control method for a full-power fuel cell air compressor,

[0070] Specifically include the following steps:

[0071] Step S1: construct fuel cell cathode flow model;

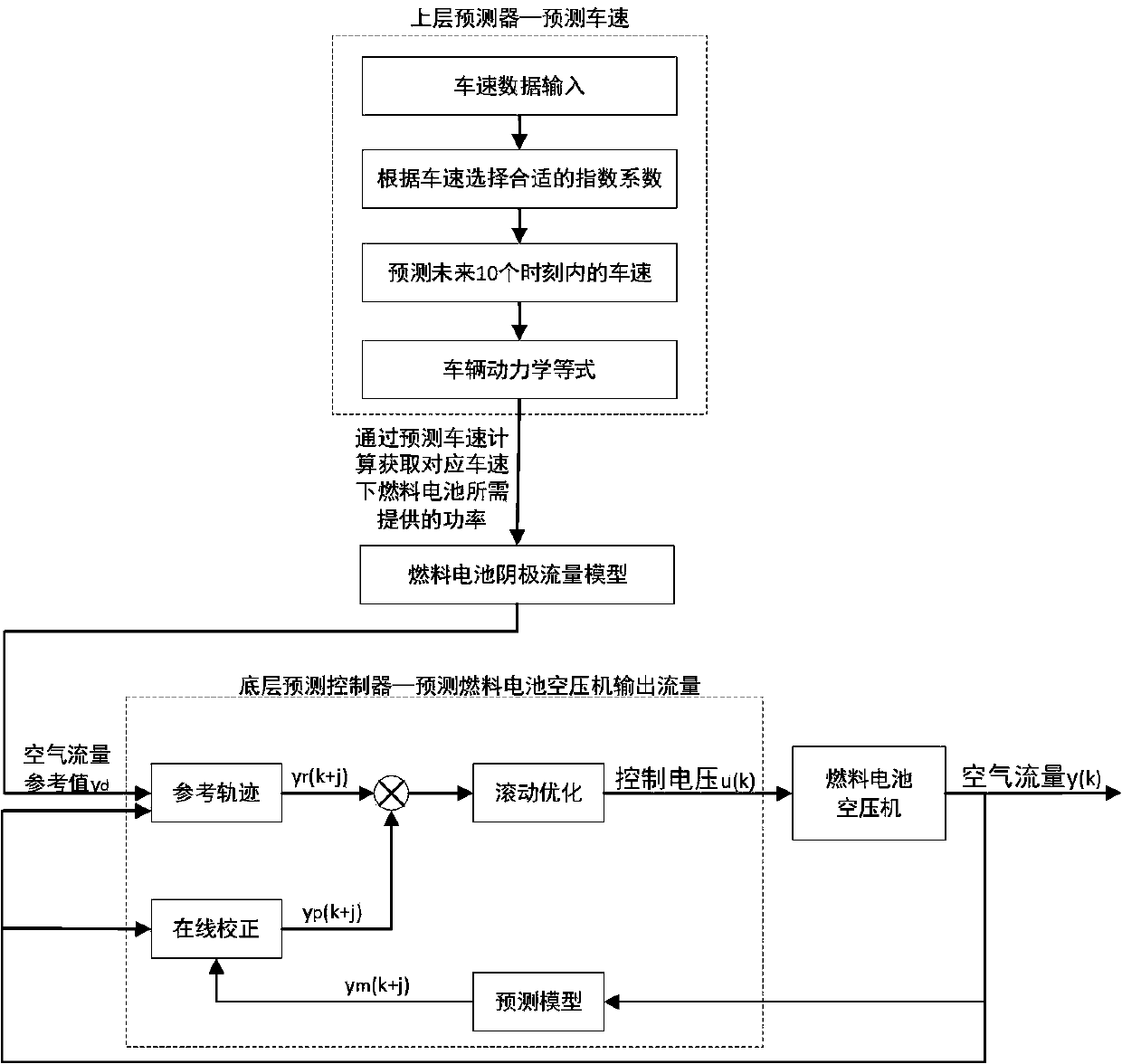

[0072] Step S2 constructs a two-layer predictive control system, including an upper-level predictor and a lower-level predictive controller;

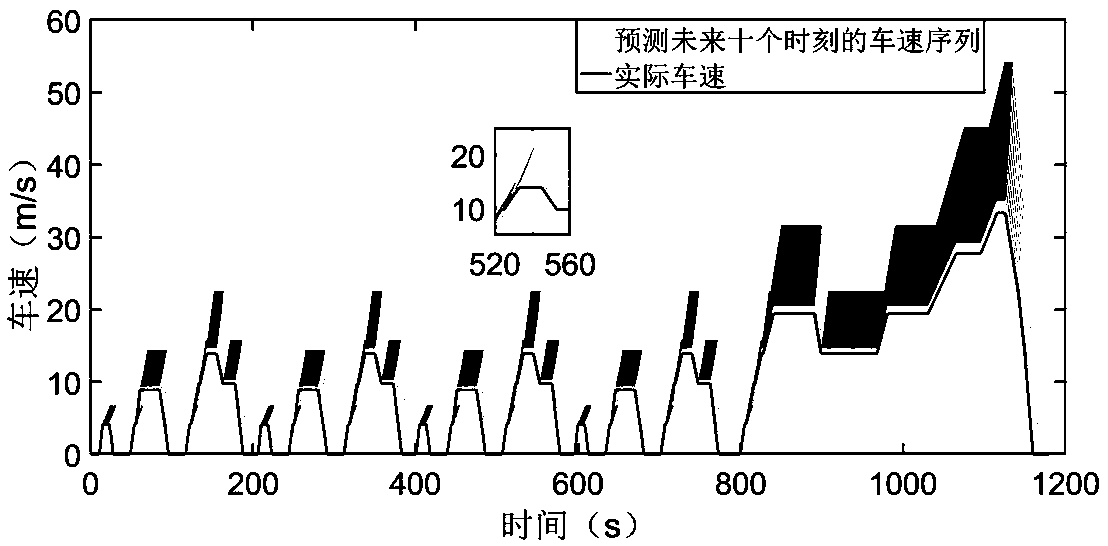

[0073] Step S3: The upper-layer predictor takes the real-time speed V(k) measured by the speed sensor as input, and predicts the vehicle speed sequence {V(k+1), V(k +2),...,V(k+10)}, through the vehicle dynamics relation, the power {P r (k+1),P r (k+2),...,P r (k+10)};

[0074] Step S4: input the power required to be provided by the fuel cell in the next ten moments into the fuel cell cathode flow model, and obtain the air flow reference value at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com