An intelligent temperature-adjusting ore drying furnace

A technology of intelligent temperature adjustment and drying furnace, which is applied in drying, drying machine, dry cargo handling, etc., can solve the problems of water not being reused effectively, reducing drying efficiency, water waste, etc., to increase workability Wide range, convenient operation, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

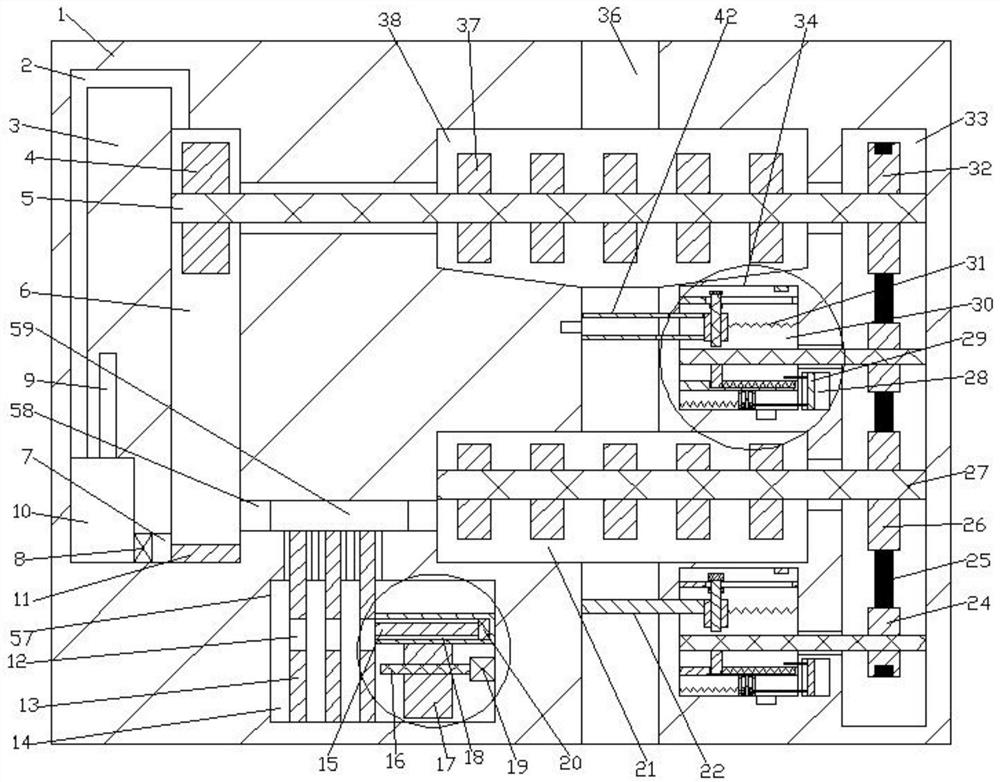

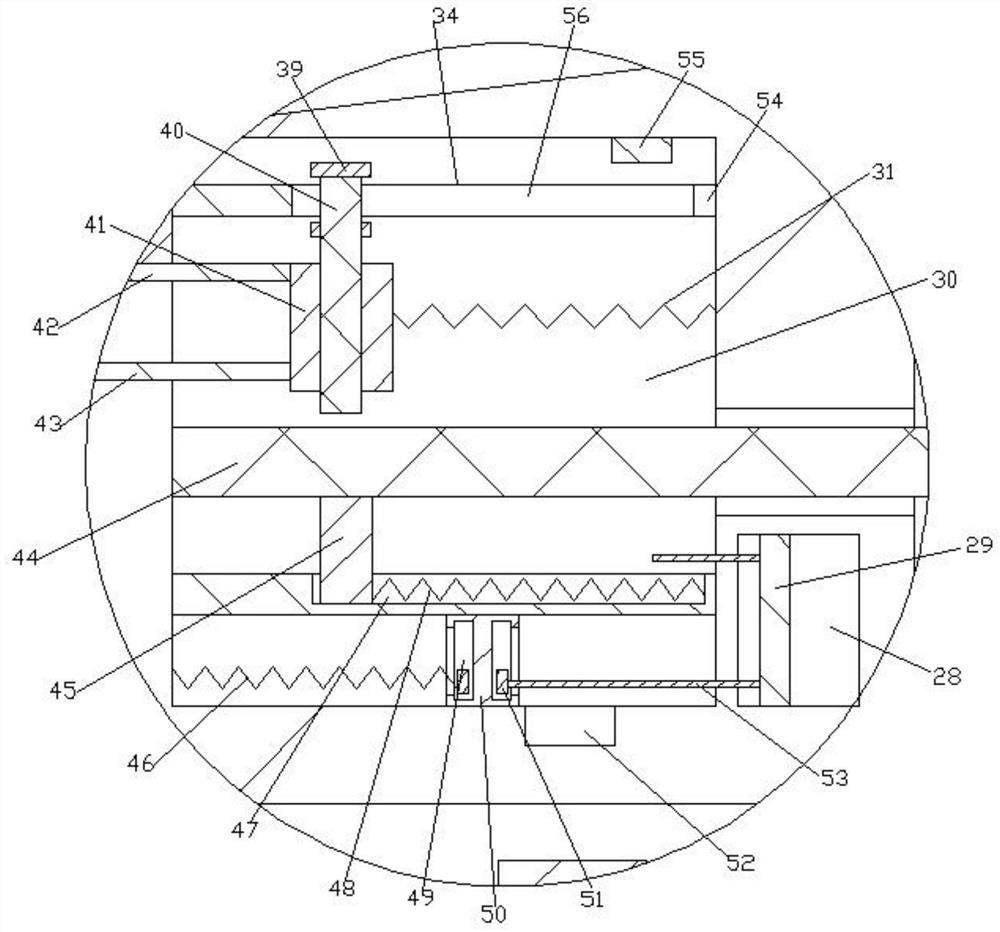

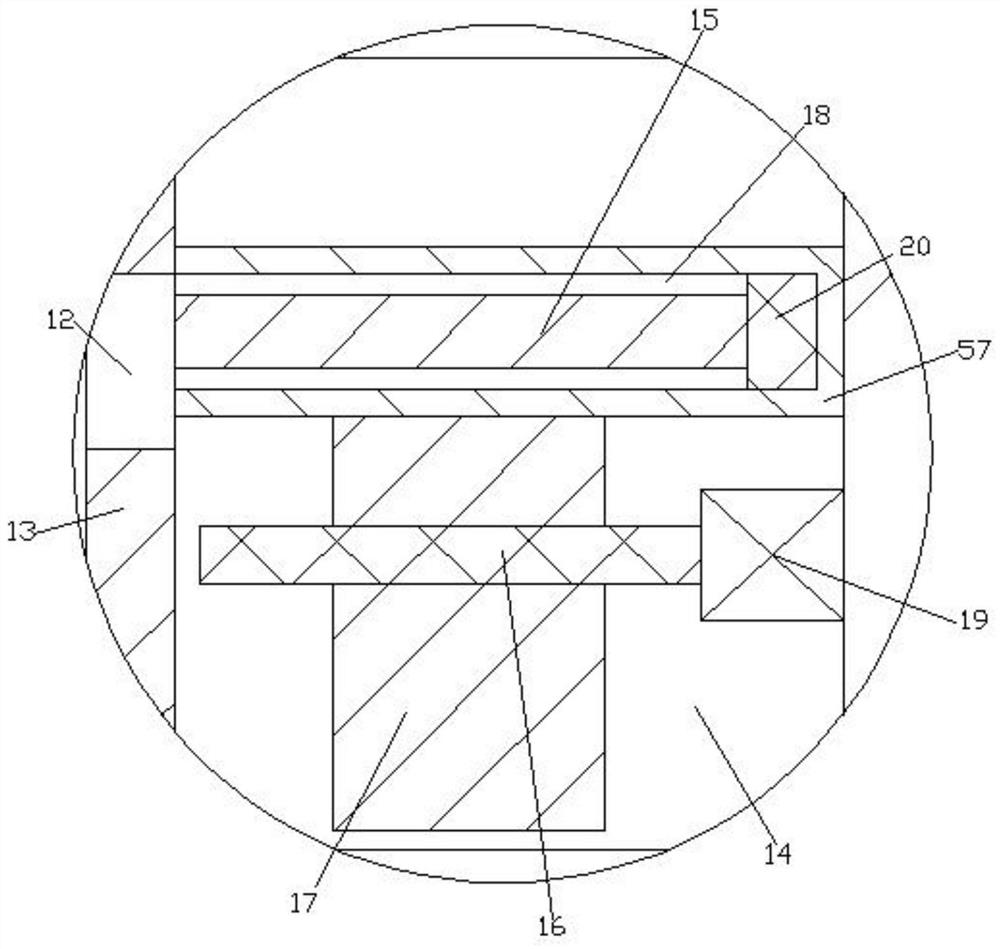

[0014] see Figure 1-4 , an embodiment provided by the present invention: an intelligent temperature-regulating ore drying furnace, including a drying furnace 1 and a drain chamber 38 and a drying chamber 21 located in the drying furnace 1, and the drying chamber 21 The right end wall is provided with a driven chamber 33, the left end wall of the drying chamber 21 is provided with an evaporation chamber 6, and the driven chamber 33 is provided with a left end that runs through the drain chamber 38 and is located in the evaporation chamber 6. The driven shaft 5, the driven chamber 33 is also provided with a stirring shaft 27 whose left end is located in the drying chamber 21, the stirring shaft 27 located in the drying chamber 21 and the draining chamber 38 The driven shaft inside is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com