A pressure relief method for bottom coal in fully mechanized caving mining in steeply inclined coal seams

A steeply inclined, coal seam technology, applied in ground mining, mining equipment, mining equipment, etc., can solve the problems such as the inability to effectively reduce the impact risk of clamping the coal body, the high clamping stress of the bottom coal, and the unreasonable parameters. The effect of small impact rock pressure dynamic disaster risk, reducing impact risk and increasing fracture development degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below.

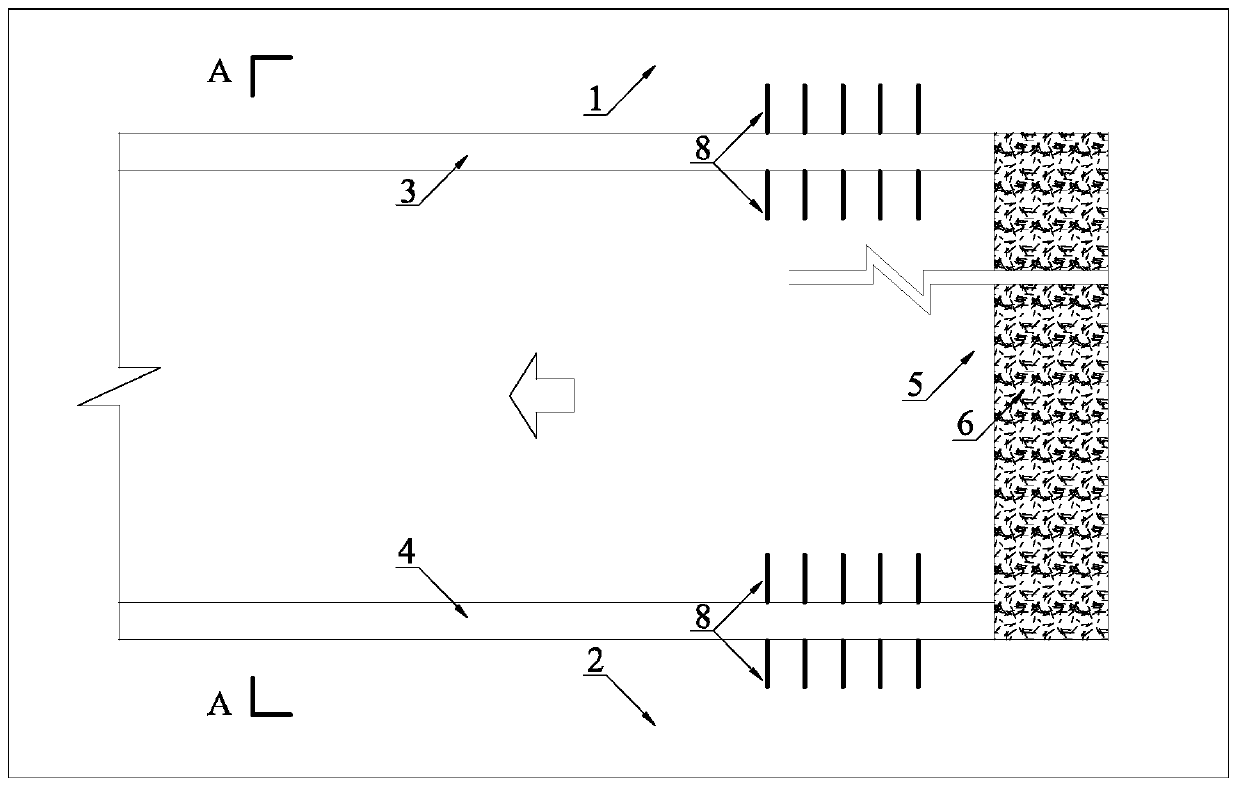

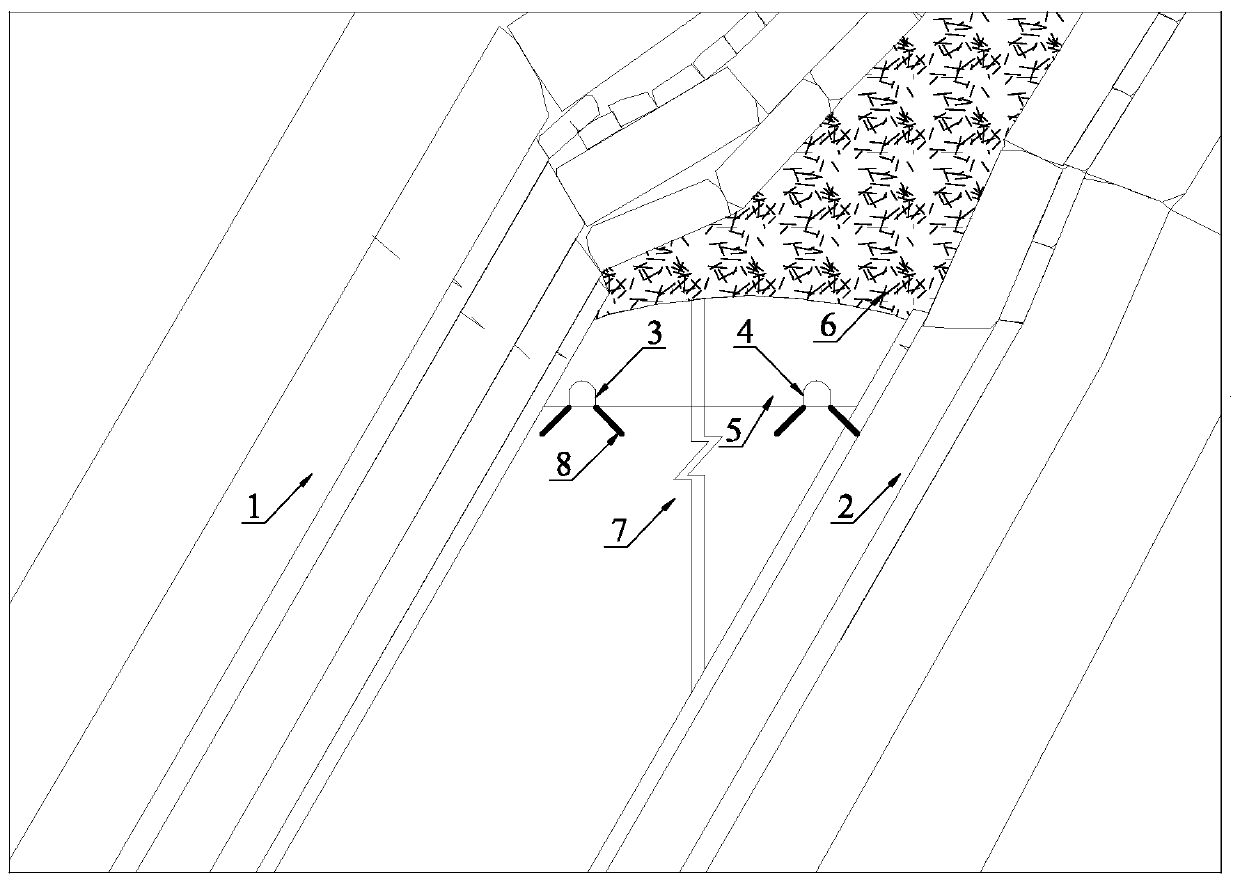

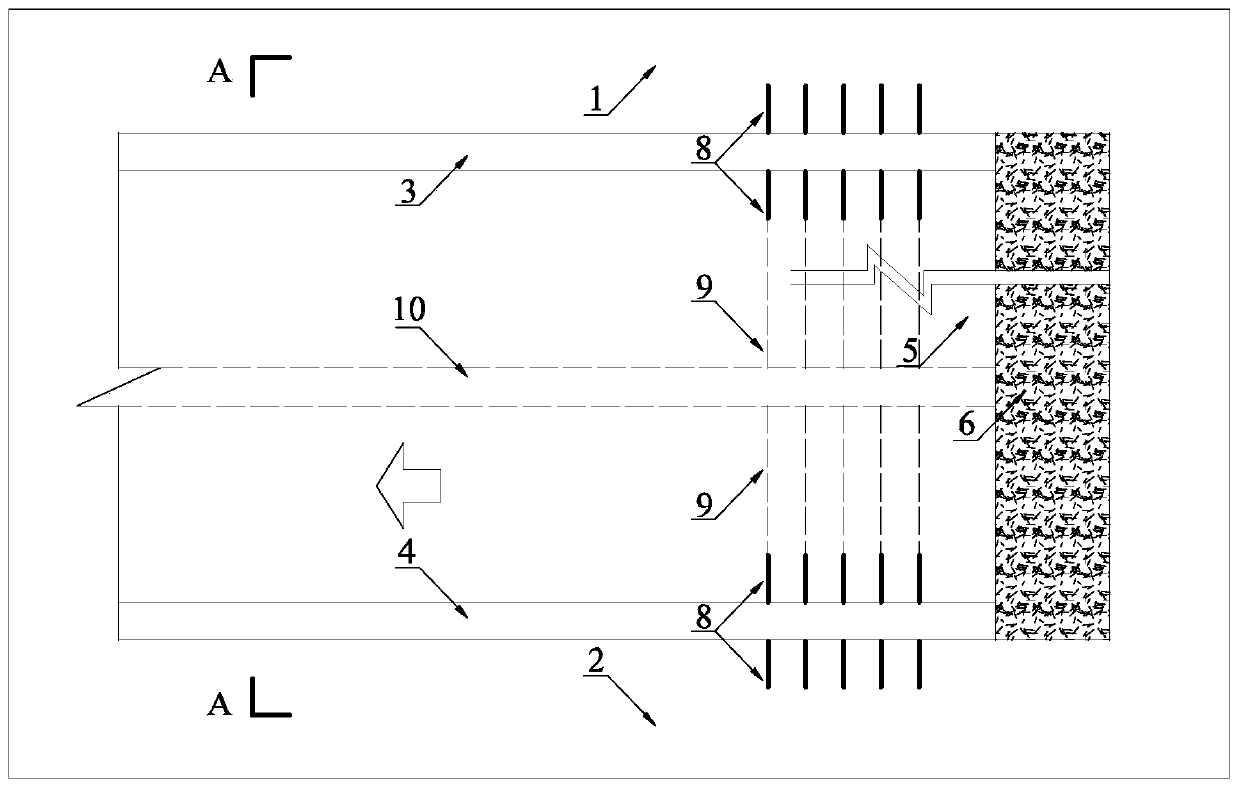

[0025] As shown in the figure, the concrete steps of the present invention are:

[0026] A. Carry out roadway pressure relief blasting on the bottom coal of the working face:

[0027] a. Drill blasting and pressure relief drilling holes 8 at the lower side corner of the working face transportation chute 3 and return air chute 4 close to the coal body side of the working face, and arrange multiple blasting pressure relief holes 8 in a single row forward along the lower side corner Drill holes 8, and the distance between the blasting pressure relief drilling 8 farthest from the working face and the working face is not less than 150m; each blasting pressure relief drilling 8 is perpendicular to the mining roadway and at 45° to the horizontal direction of the coal body The included angle is to install a plurality of explosive tubes in each blasting pressure relief borehole 8, and make the amount of explosive in each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com