Automatic glass stacking machine

A palletizer, automatic technology, applied in the direction of conveyors, conveyor objects, object stacking, etc., can solve the problems of large rotation radius, large space occupation, inability to move horizontally, and heavy structure, etc., to achieve intelligent automatic palletizing , reasonable structural design, and the effect of ensuring the efficiency of palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

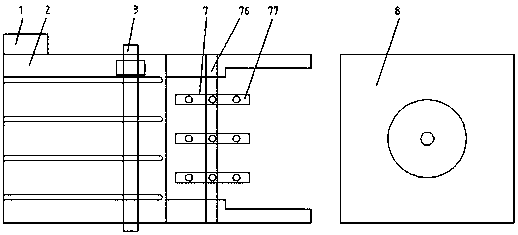

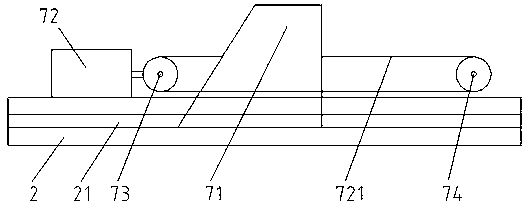

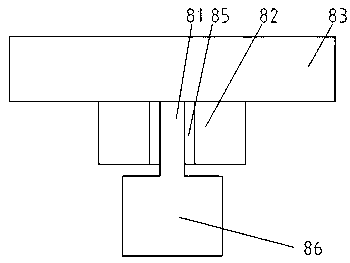

[0023] Figures 1-3 and 5-7 show the first embodiment of the present invention: a glass automatic palletizer, including a frame 2 and a control center 1, the control center 1 is controlled by PLC programming, and belongs to the existing If you have the technology, you can compile corresponding programs according to your actual needs to realize the control function. One end of the frame 2 is connected with a cutting mechanism 3, and the other end of the frame 2 is provided with a tray for placing glass after stacking. An automatic palletizing mechanism 7 is provided on the frame 2 to automatically palletize the cut glass and put the glass pallet on the pallet. After the palletizing is completed, the pallet is transported away to ensure the continuous and stable follow-up work to realize glass assembly line production from cutting to palletizing, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com