Packaging device used for fine dried noodle production

A technology for dried noodles and wrapping paper, which is applied in the direction of packaging material feeding device, packaging, transportation and packaging, etc., can solve the problems of easily broken noodles, low production efficiency, high labor intensity, etc., so as to reduce breakage, generation of debris, and weight deviation. Small, consistent length effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

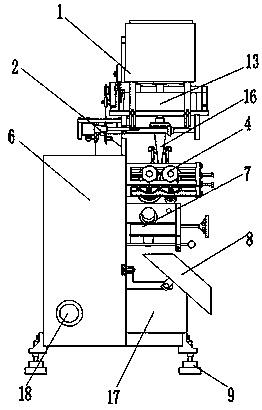

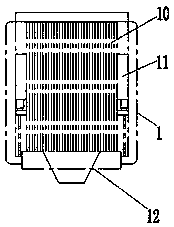

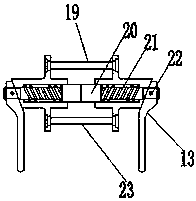

[0023] refer to Figure 1-4 , a packaging device for noodle production, comprising a cabinet 6 and a slag collection box 17, a cut-off structure 13 is fixed on one side of the top outer wall of the cabinet 6 by bolts, and a discharge box 1 is fixed on the top outer wall of the cut-off structure 13 by bolts, the cabinet 6 There is a through groove on the outer wall of one side close to the slag collecting box 17, and a rotating motor is fixed on the inner wall of the through groove through bolts, the output shaft of the rotating motor is sleeved with a rotary disc 2, and the outer wall of the rotary disc 2 is fixed with a bundle Cylinder 4 and heat sealer 7, the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com