Gas and liquid separator

A gas-liquid separator and separator technology, which is applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the problem of insufficient rotating linear speed, and achieve the effects of large centrifugal force, small rotation radius and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

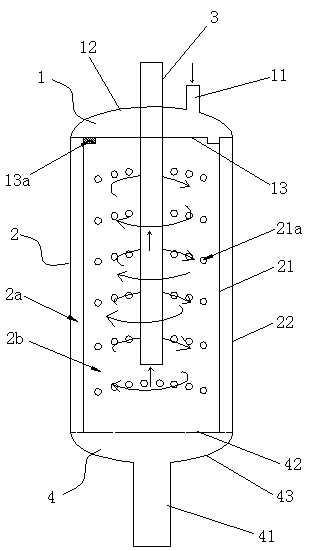

[0024] Embodiment one, as Figure 1 to Figure 2 as shown,

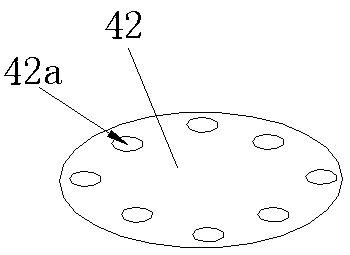

[0025] A gas-liquid separator, comprising a separator body, a steam chamber 1 is arranged on the upper part of the separator body, an air inlet pipe 11 is arranged on the steam chamber 1, and a cylindrical jacket 2 is arranged below the steam chamber 1, A water collection channel 2a is formed between the inner plate 21 and the outer plate 22 of the jacket 2, and a cylinder cavity 2b is formed in the middle of the separator body inside the inner plate 21 of the jacket 2, and the center of the cylinder cavity 2b is provided with The air outlet pipe 3, the upper end of the air outlet pipe 3 extends out of the separator body; the inner layer plate 21 of the jacket 2 is provided with a water outlet hole 21a, and the bottom of the jacket 2 is provided with a water collection chamber 4, and the water collection chamber 4 is connected with the The water collection channel 2a communicates with each other, the lower part of th...

Embodiment 2

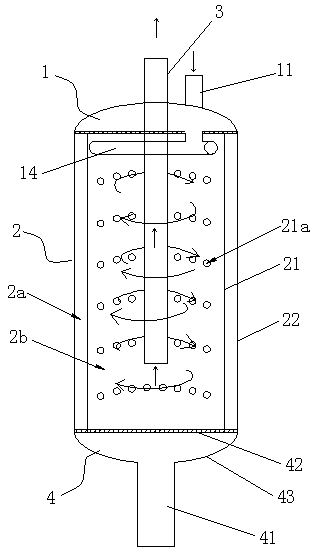

[0030] Embodiment two, such as Figure 3 to Figure 4 as shown,

[0031] The structure of the gas-liquid separator in this embodiment is similar to that in Embodiment 1, the difference is that in this embodiment, a vent pipe 14 is connected to the steam chamber 1, and the vent pipe 14 is placed on the upper part of the cylinder cavity 2b , and arranged along the diameter direction, the air inlet is the air outlet pipe 14a which is correspondingly arranged at both ends of the air pipe 14 .

[0032] In the embodiment, the air outlet pipe 14a is perpendicular to the ventilation pipe 14, and the air outlet pipes 14a at both ends face opposite directions. In this way, the steam enters the cylinder cavity 2b in a tangential direction, so as to obtain a greater linear velocity.

[0033] working principle:

[0034] The steam enters the steam chamber 1 from the air inlet pipe 11, and then enters the cylinder chamber 2b along the tangential direction from the air inlet arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com