System and method for controlling furnace body process based on big data analysis

A big data and furnace body technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of difficult maintenance, impact generation, difficult maintenance and maintenance, etc., to optimize production and increase production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0033] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

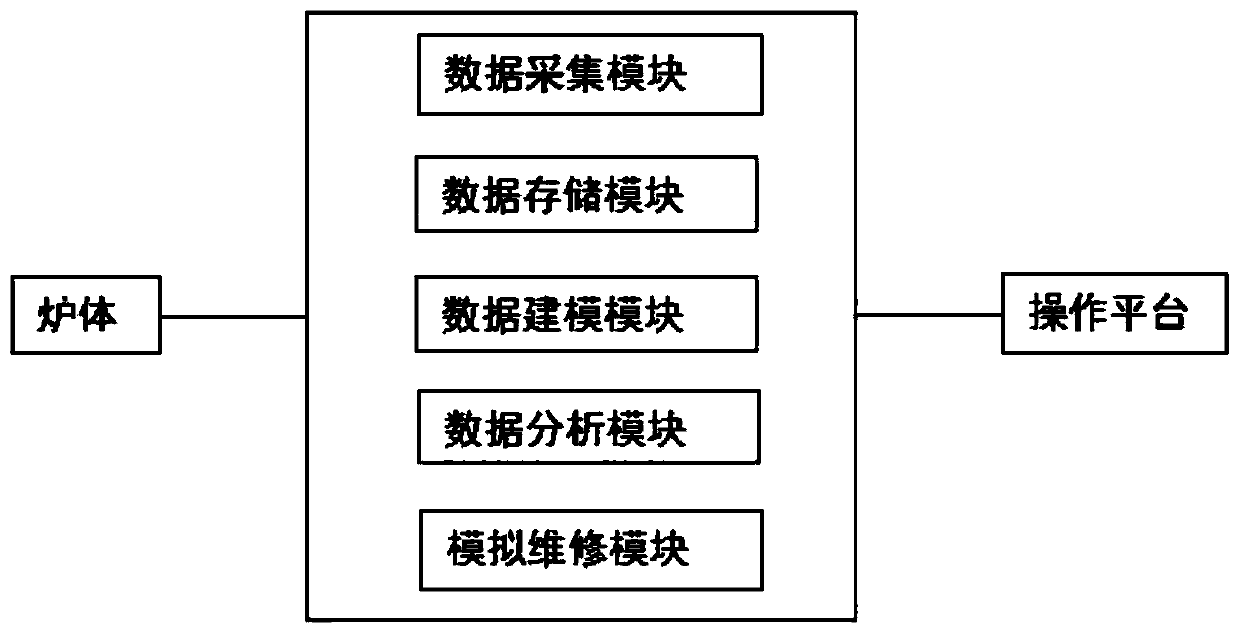

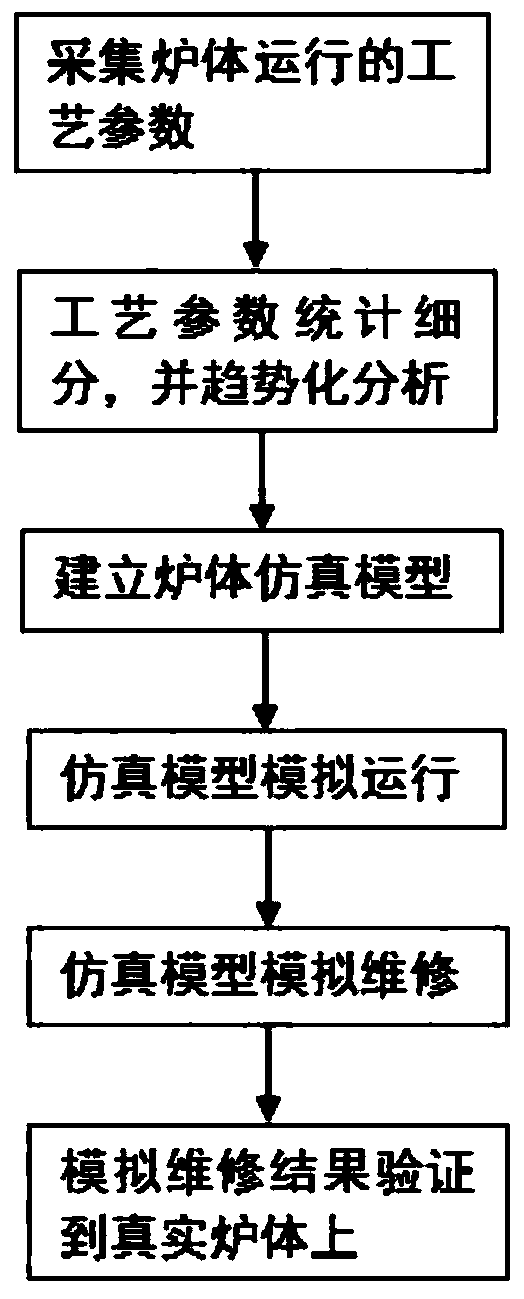

[0034] Such as Figure 1-2 As shown, a system for controlling the furnace process based on big data analysis, including a data acquisition module, a data storage module, a data modeling module, a model analysis module and a simulation maintenance module;

[0035] The data collection module collects process parameter values of temperature, gas saturation, pressure, flow rate, rotational speed, and material ratio during furnace operation;

[0036] The data storage mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com