Automatic purging system for carbon black flue gas desulfurization oxidation air pipeline

A technology of oxidizing wind and oxidizing blower, which is applied in the field of desulfurization, and can solve the problems of high water content in gypsum, affecting the oxidation effect of slurry in the desulfurization tower, and blockage of the outlet nozzle of the oxidizing air pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

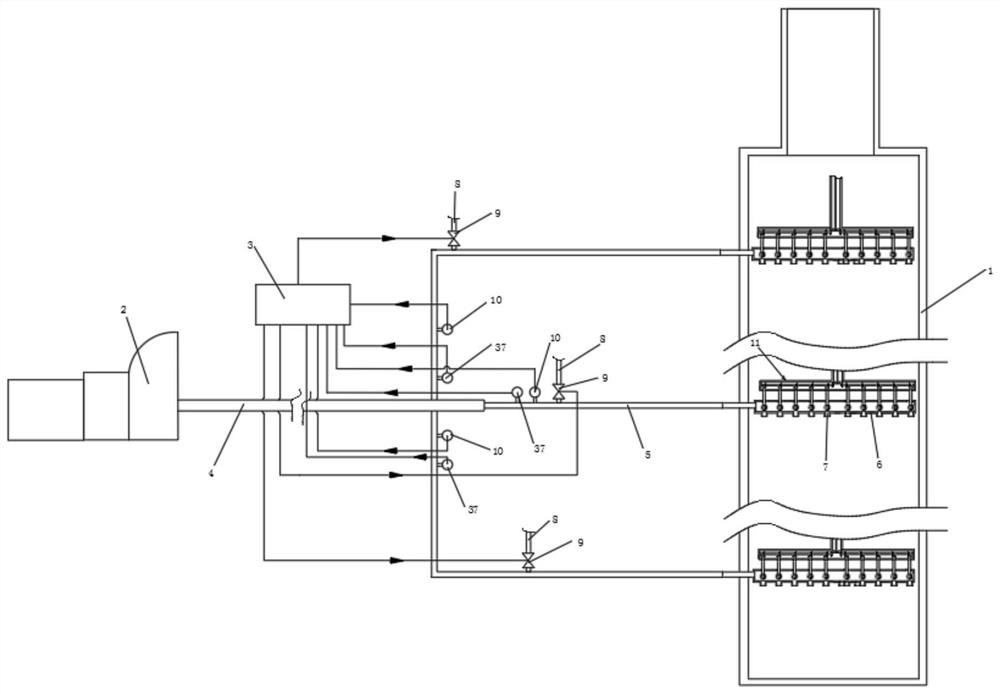

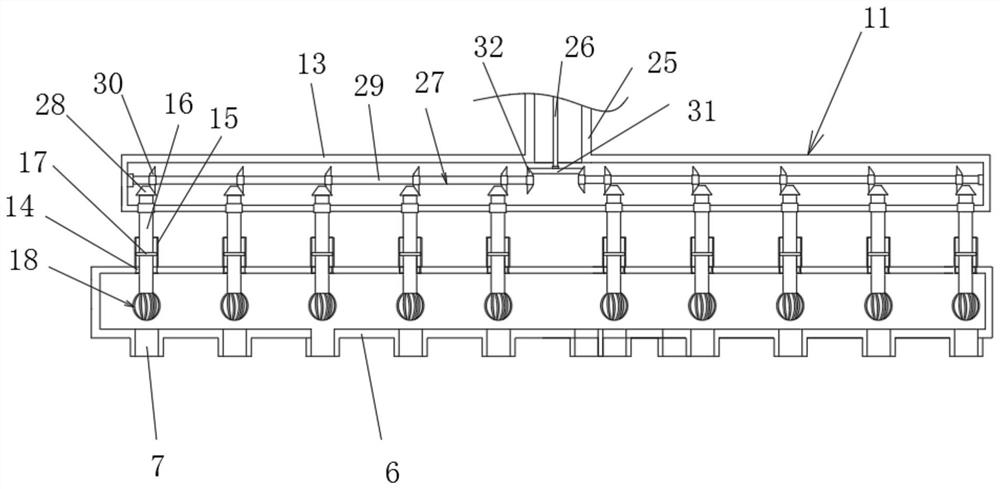

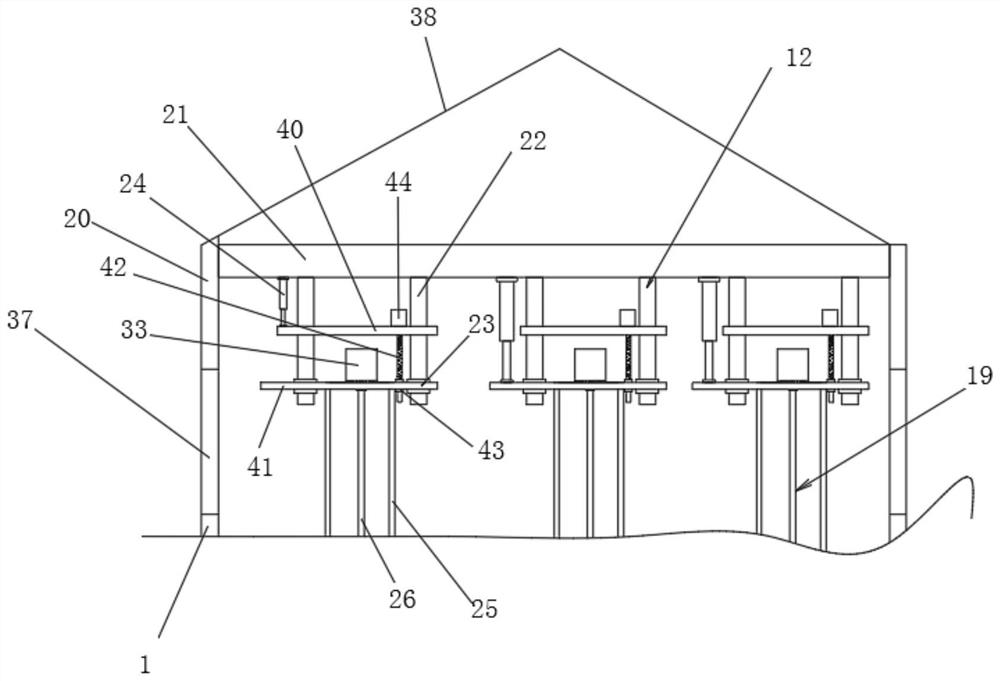

[0028] Example: such as Figure 1-5 As shown, a carbon black flue gas desulfurization oxidation air pipeline automatic purging system of the present invention comprises a desulfurization tower 1, an oxidation fan 2 and a PLC controller 3, and the outlet end of the oxidation fan 2 is connected with an oxidation air main pipe 4, The desulfurization tower 1 is provided with an oxidation air branch pipe 5 that enters the desulfurization tower 1 from top to bottom, and the inner end of the oxidation air branch pipe 5 is provided with an air outlet pipe 6, and a plurality of The outlet nozzle 7 facing downwards, and the front end of each oxidizing wind branch pipe 5 is provided with a water inlet pipe 8 communicating with the oxidizing wind branch pipe 5, and the water inlet pipe 8 is provided with an electromagnetic control valve 9, and the oxidizing wind branch pipe 5 The front end is also provided with a flow meter 10 inside the oxidation air branch pipe 5, and the desulfurizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com