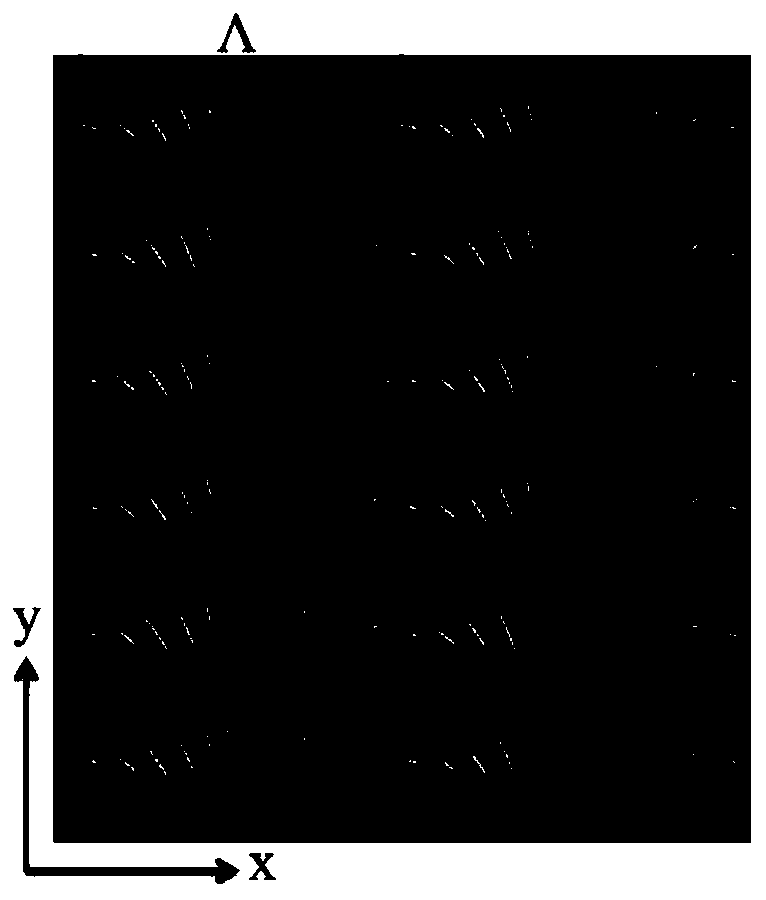

Preparation method of liquid crystal polarization grating

A liquid crystal polarization grating and liquid crystal cell technology, applied in diffraction gratings, polarizing elements, optics, etc., can solve the problems of complex optical path, difficult mass production, poor flexibility, etc., and achieve strong anti-interference ability, simple structure, and large adjustment range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

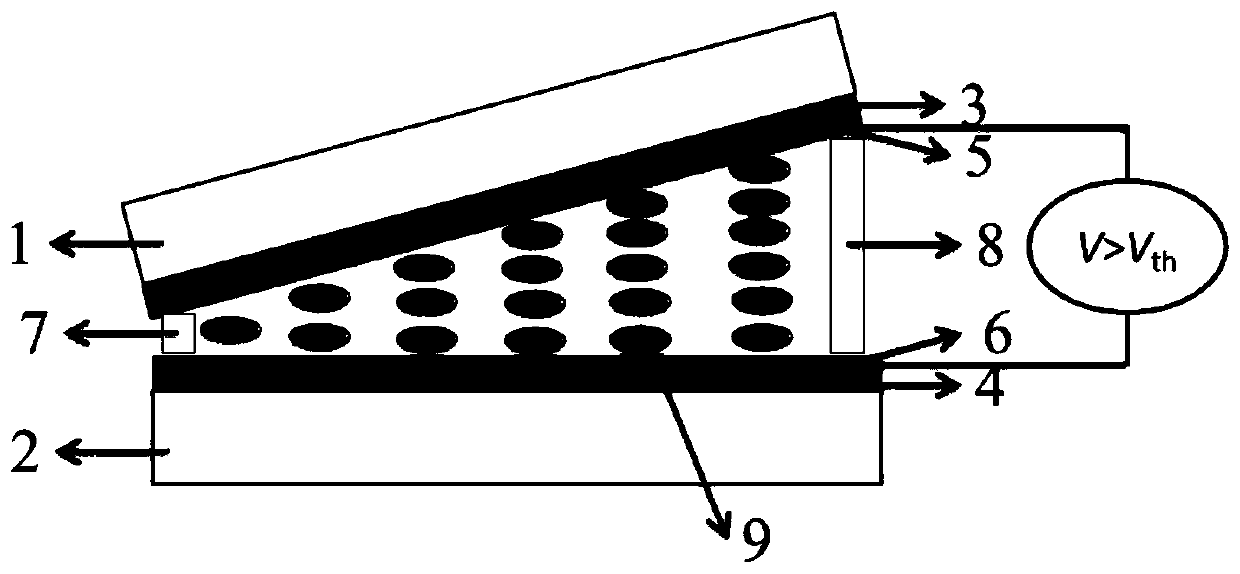

[0035] 1. Preparation of wedge-shaped liquid crystal cell

[0036] 1) figure 2 It is a structural schematic diagram of a wedge-shaped liquid crystal cell, which includes a glass substrate, a gap spacer, a conductive layer, an alignment layer, a liquid crystal layer, and a voltage control unit.

[0037] 2) First, use acetone, ethanol and ultrapure water to clean the substrate. After drying, evaporate an ITO conductive film on one side of the substrate with a thickness of about 20 nm. Spin-coat a rubbing alignment agent on the conductive film side of the glass substrate, 230 Cure at high temperature, and then perform rubbing orientation under a rubbing machine, make a frame glue on a part of the glass substrate, place spacers with 3 μm and 100 μm gaps on both sides, and place the other part of the glass substrate antiparallel on the substrate. Pressed into a box, filled with liquid crystal and then sealed;

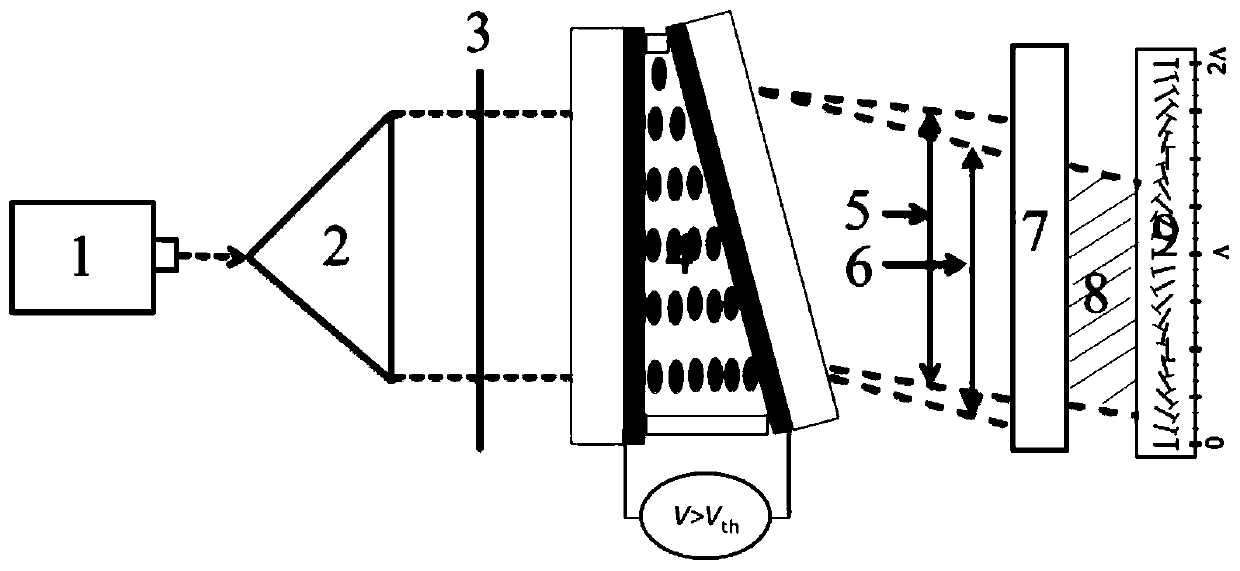

[0038] 2. Preparation of light-controlled orientation glass substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com