Compressor high pressure difference starting control method, device and air conditioner

A technology of compressors and sub-compressors, applied in the field of compressors, can solve problems such as the need to open pressure balance valves, and achieve the effects of reducing production costs, improving user experience, and high-capacity output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

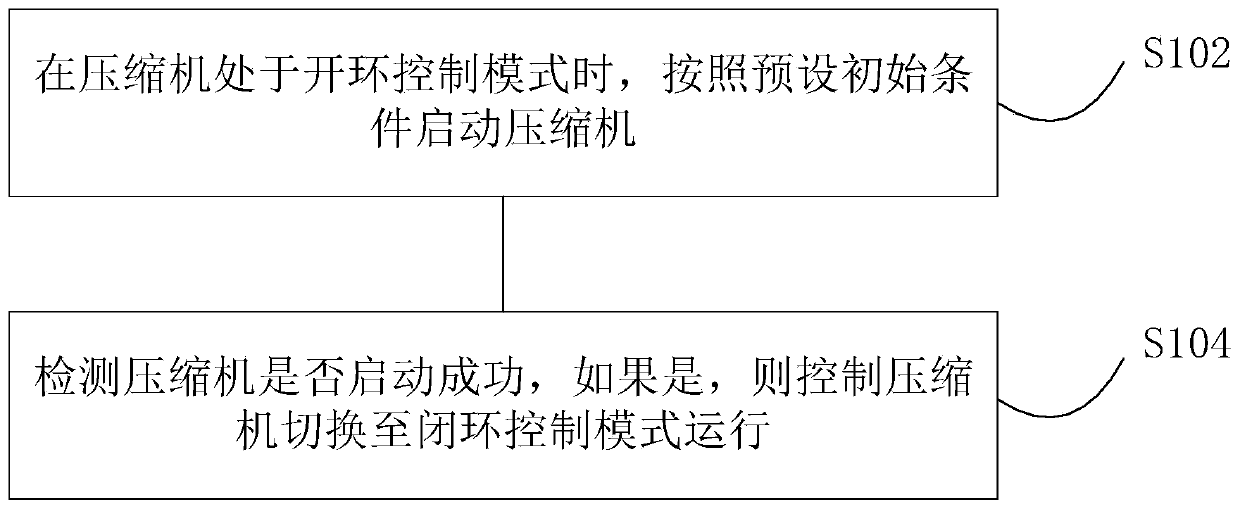

[0023] In the preferred embodiment 1 of the present invention, a compressor start-up control method is provided. This control method can be directly applied to various multi-compressor systems. through the corresponding program. Specifically, figure 1 An alternative flowchart showing the method, such as figure 1 As shown, the method includes the following steps S102-S104:

[0024] S102: When the compressor is in the open-loop control mode, start the compressor according to the preset initial condition;

[0025] S104: Detect whether the compressor is started successfully, if so, control the compressor to switch to the closed-loop control mode to run.

[0026] In the present invention, both open-loop control and closed-loop control belong to the operating modes used by the compressor. Closed-loop (closed-loop structure) is also called feedback control system, which compares the measured value of the system output with the desired given value, thereby generating a deviation s...

Embodiment 2

[0037]Based on the compressor start-up control method provided in the above-mentioned embodiment 1, a compressor start-up control device is also provided in preferred embodiment 2 of the present invention, specifically, image 3 shows an optional structural block diagram of the device, such as image 3 As shown, the device includes:

[0038] An open-loop control module 302, configured to start the compressor according to preset initial conditions when the compressor is in an open-loop control mode;

[0039] The closed-loop control module 304 is connected with the open-loop control module 302, and is used to detect whether the compressor starts successfully, and if so, controls the compressor to switch to the closed-loop control mode to run.

[0040] In the above embodiment, a compressor high pressure difference startup control device is provided. By starting the compressor according to the preset initial conditions, the compressor operates in an open-loop control mode, and th...

Embodiment 3

[0049] Based on the compressor start-up control method provided in the above-mentioned embodiment 1, a compressor system is also provided in the preferred embodiment 3 of the present invention, including a main compressor and a sub-compressor, and the sub-compressor adopts the above-mentioned compressor Start the control method.

[0050] In the above embodiment, a method for starting and controlling the high pressure difference of the compressor is provided. First, start the compressor according to the preset initial conditions. At this time, the compressor operates according to the open-loop control mode, and then check whether the compressor is started successfully. If so, Then control the compressor to switch to the closed-loop control mode to run. Through the above start-up method, it is possible to realize fast and smooth start-up without opening the gas bypass of the unit, which solves the problem in the prior art that the compressor of the multi-system type needs to ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com