Air filter

A technology of air filter and filter element, which is applied in fuel air filter, combustion air/combustion-air treatment, machine/engine, etc. It can solve the problems that the horizontal dust collection surface cannot discharge ash in time and the maintenance cycle of filter element is short. , to achieve the effect of prolonging the maintenance cycle, reducing maintenance costs and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

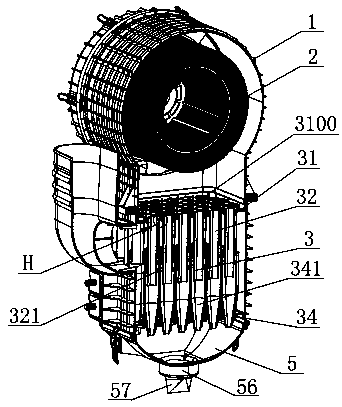

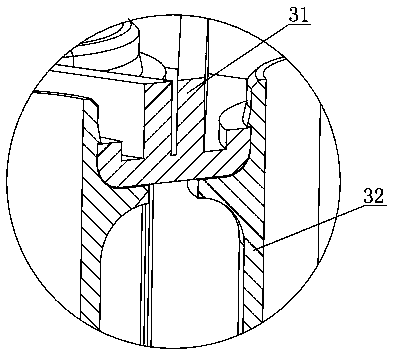

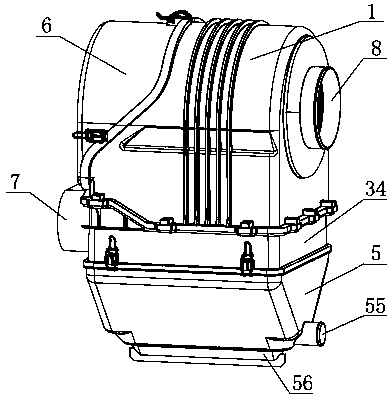

[0048] Such as image 3 , Figure 4 As shown, the present invention consists of a housing 1, a pre-filter assembly 3 and a dust collection cover assembly 5 from top to bottom. One side of the housing 1 is provided with an air outlet 8, and the opposite side is fixed with a buckle. The outer end cover 6 is provided with a sealing member 2 9 between the shell 1 and the outer end cover 6; the inside of the shell 1 and the outer end cover 6 is provided with a horizontal cylindrical main filter element 2, and the main filter element 2 is provided with a concentric safety valve. The filter element 10 , the inner filter element chamber 11 of the safety filter element 10 communicates with the air outlet 8 . The lower end of the shell 1 is fixed with the pre-filter assembly 3 by fasteners, and a special-shaped sealing ring 33 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com