Fiberglass mesh ultra-high performance concrete thermal insulation and decoration integrated fabricated external wallboard

A glass fiber, ultra-high performance technology, used in thermal insulation, walls, building components, etc., can solve the problems of affecting popularization and use, high cost, and achieve the effects of considerable economy, weight reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

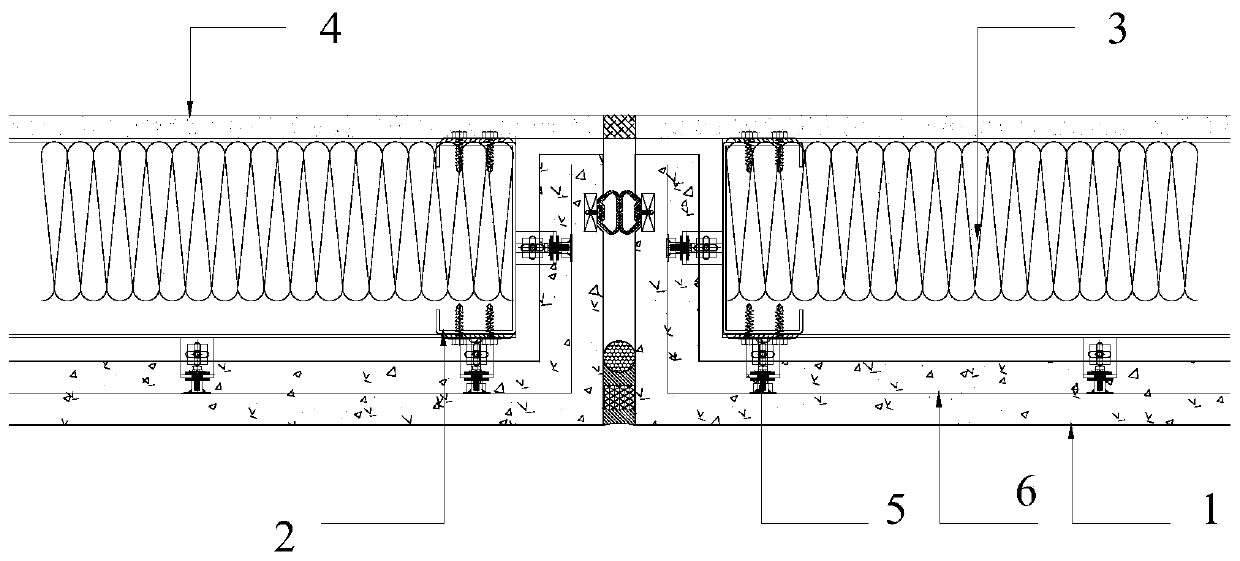

[0034] see figure 1 , the present invention provides a technical solution: a glass fiber grid ultra-high performance concrete thermal insulation and decoration integrated assembled exterior wall panel, including glass fiber grid ultra-high performance concrete surface layer, pre-embedded stainless steel sleeve bolt assembly, light weight Steel keel, insulation layer, high-strength inner slab; the concrete surface layer is made of glass fiber grid ultra-high performance concrete, and the surface layer is connected to the light steel keel through pre-embedded stainless steel sleeve bolt components and angle steel processing parts , the thermal insulation layer is arranged between the concrete surface layer and the high-strength inner page board, and the high-strength inner page board is connected to the light steel keel through self-tapping self-drilling nails.

[0035] In order to better understand the present invention, the present invention also proposes a method for processi...

Embodiment 2

[0050] A fiberglass grid ultra-high performance concrete thermal insulation and decoration integrated assembled exterior wall panel, including glass fiber grid ultra-high performance concrete surface layer, pre-embedded stainless steel sleeve bolt assembly, light steel keel, insulation layer, high-strength inner page slab; the concrete surface layer is formed by pouring glass fiber mesh ultra-high performance concrete, and the surface layer is connected with the light steel keel through pre-embedded stainless steel sleeve bolt components, angle steel processing parts, and the insulation layer is set on the concrete surface layer Between the high-strength inner page board and the high-strength inner page board, the high-strength inner page board is connected to the light steel keel through self-tapping and self-drilling nails.

[0051] In order to better understand the present invention, the present invention also proposes a method for processing and manufacturing an integrated ...

Embodiment 3

[0066] A fiberglass grid ultra-high performance concrete thermal insulation and decoration integrated assembled exterior wall panel, including glass fiber grid ultra-high performance concrete surface layer, pre-embedded stainless steel sleeve bolt assembly, light steel keel, insulation layer, high-strength inner page slab; the concrete surface layer is poured from glass fiber grid ultra-high performance concrete, and the surface layer is connected with the light steel keel through the pre-embedded stainless steel sleeve bolt assembly, angle steel processing parts, and the insulation layer is set on the concrete surface Between the layer and the high-strength inner page board, the high-strength inner page board is connected to the light steel keel through self-tapping self-drilling nails.

[0067] In order to better understand the present invention, the present invention also proposes a method for processing and manufacturing an integrated assembled exterior wall panel of glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com