Special clamping fastening type assembling gasket structure

A sheet structure, fastening technology, applied in the field of snap fastening assembly gasket structure, can solve the problems of low installation efficiency, complex structure, safety hazards of mechanical equipment connection firmness, etc., to achieve convenient assembly and good stability , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

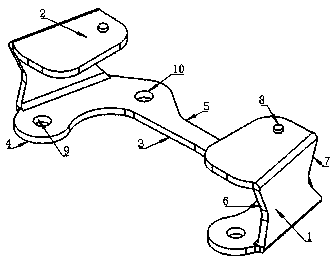

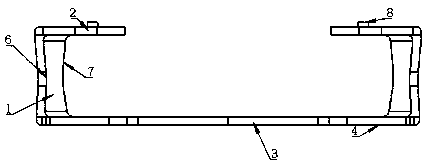

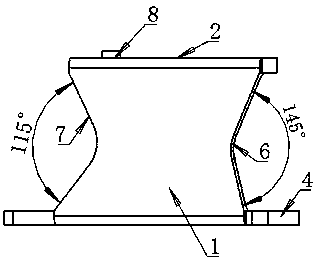

[0018] Such as Figure 1 to Figure 7 As shown in the figure, a special clamping and fastening assembly gasket structure is produced by integral molding, which makes the overall structural strength better, and it is more convenient to assemble during use. Connected with the assembly structure, it can be better connected with the assembly parts, and it can also play a certain anti-falling effect after assembly, making the overall assembly efficiency higher and the assembly stability better. Reliable, by setting different assembly grooves at different assembly positions, it can be better connected with the assembly parts, the tightness of the connection is more reliable, and the connection strength after fastening is also better, so that It can make the stability of mechanical equipment more reliable, and make the safety of mechanical equipment higher when in use. It includes a U-shaped gasket main structure 1, and the left and right positions of the upper end of the U-shaped ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com