Rainwater classified collection device and method

A collection device and rainwater technology, applied in water supply devices, drinking water devices, runoff/rainwater treatment, etc., can solve the problem of low rainwater collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

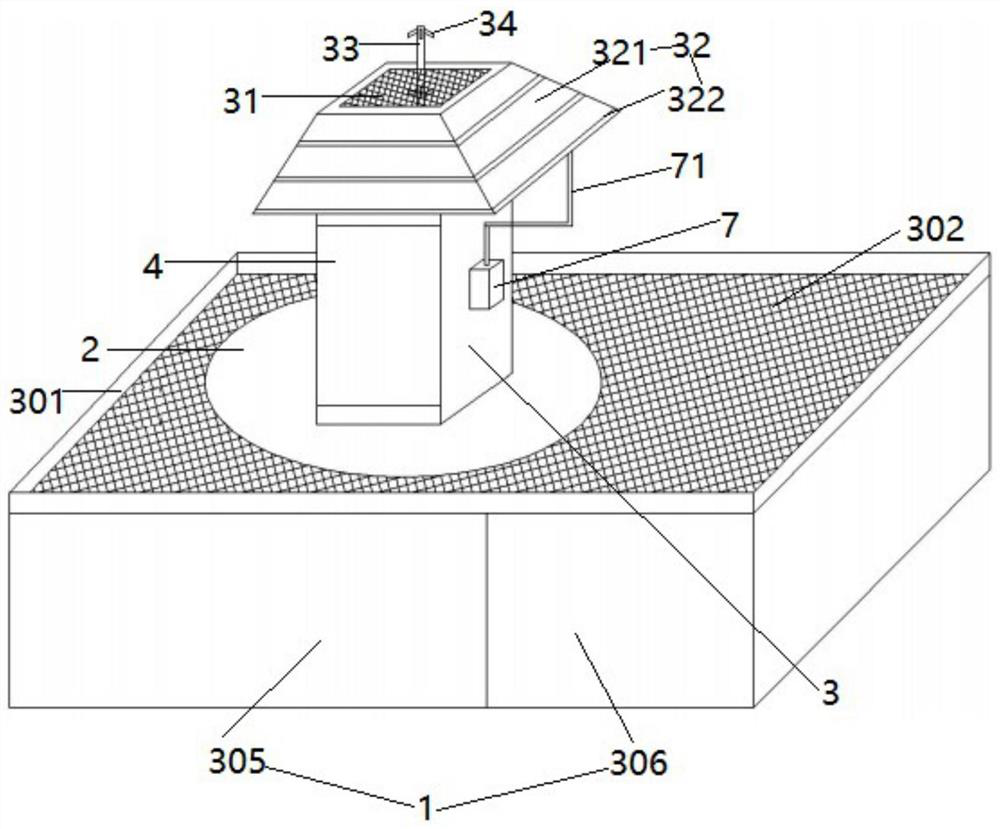

[0045] Such as figure 1 , figure 2 The shown embodiment is a kind of rainwater classification and collection device, comprising a reservoir 1, a turntable 2 arranged on the reservoir, a vertical cylinder 3 arranged on the rotary disk, a filter screen 31 arranged on the opening at the upper end of the vertical cylinder, The water collecting cover 32 that is located at the upper end of the vertical tube, the vertical tube 33 with the upper end and the lower end closed above the opening, 6 nozzles 34 that are located on the vertical tube, and the solar panel 4 that is located on the vertical tube; also includes The storage battery, the controller 6, and the turntable are slidingly connected with the guide rails arranged on the reservoir. The cross-section of the vertical cylinder is rectangular. A rectangular ring-shaped support frame 322, the two cylinders 7 located on the opposite sides of the vertical tube are respectively connected to the support frame on the upper edge of ...

Embodiment 2

[0057] Embodiment 2 includes all structure and method parts of embodiment 1, such as Figure 4 , Figure 5 As shown, a column 101 is provided on the turntable on the outside of the vertical tube in Embodiment 2, a windward plate 102 is provided on the column, a trumpet-shaped air inlet hood 103 is arranged on the top of the windward plate, and a flexible material is used at the rear of the air inlet hood. The formed arc tube 104 has an opening at the rear end of the arc tube, and the size of the air inlet of the air inlet hood is greater than the size of the air outlet of the air inlet hood.

[0058] The cross-section of the windward plate is arc-shaped, and the lower end of the windward plate is in the shape of a conical surface with a small size. The air inlet of the air inlet cover is close to the inner surface of the windward plate, and the lower end of the windward plate is located There are a plurality of protrusions 1021 .

[0059] Embodiment 2 also comprises the step...

Embodiment 3

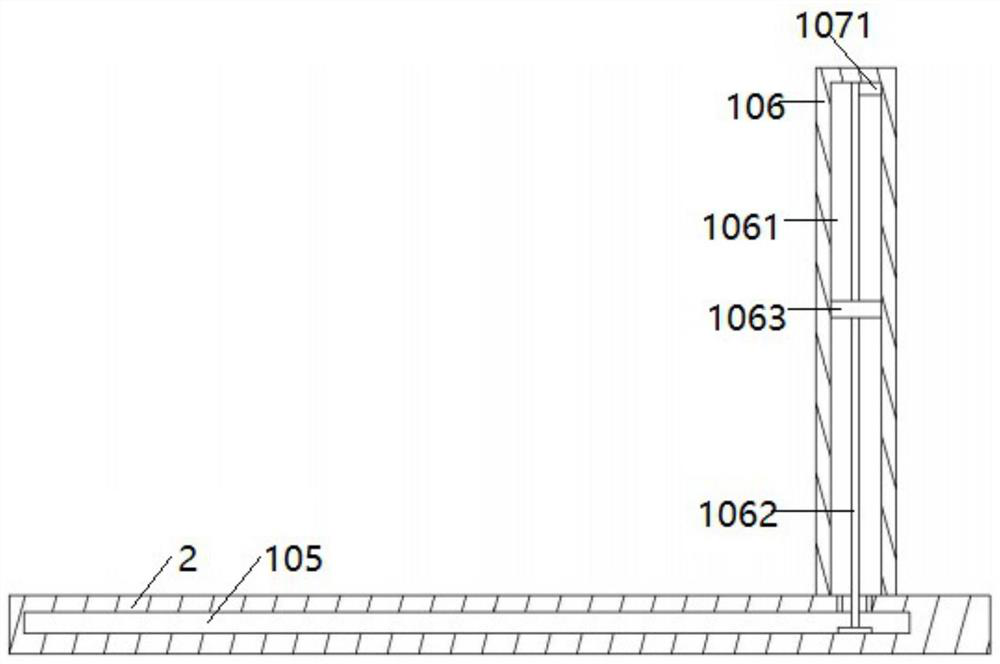

[0062] Embodiment 3 includes all structure and method parts of embodiment 1, as figure 2 , image 3 The turntable of the shown embodiment 3 is provided with an air bag 105, a vertical rod 106 is provided on the rotary table, a cavity 1061 is provided in the vertical rod, a guide rod 1062 and a piston plate 1063 are provided in the cavity, and an alarm is provided at the upper end of the cavity The button 1071 of 107, the airbag communicates with the lower part of the cavity; the bottom of the vertical tube is provided with an overturn cover plate 108, the overturn cover plate is connected with the vertical tube through a rotating shaft, the vertical tube is provided with a second motor 109, and the second motor is connected with the rotating shaft. One side of the barrel is provided with a drain port 110, such as Figure 6 As shown, the button, the alarm and the second motor are all electrically connected to the controller. The second motor is connected with the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com