Air-blowing nozzle and using method

A blowing nozzle and air curtain technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unable to discharge air from the blowing nozzle, poor welding effect, single gas flow direction, etc., to achieve good blowing effect, Improved welding quality and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

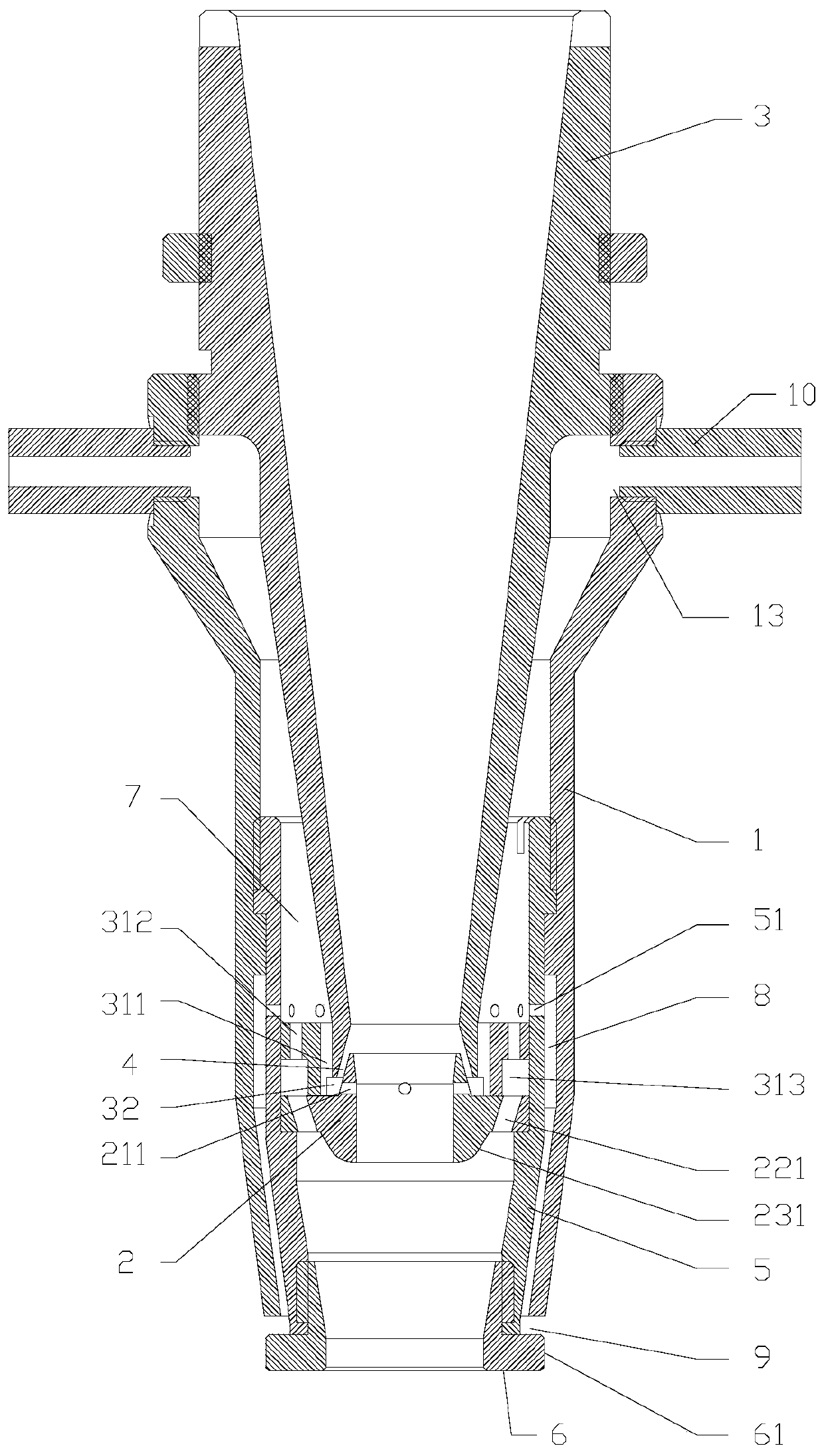

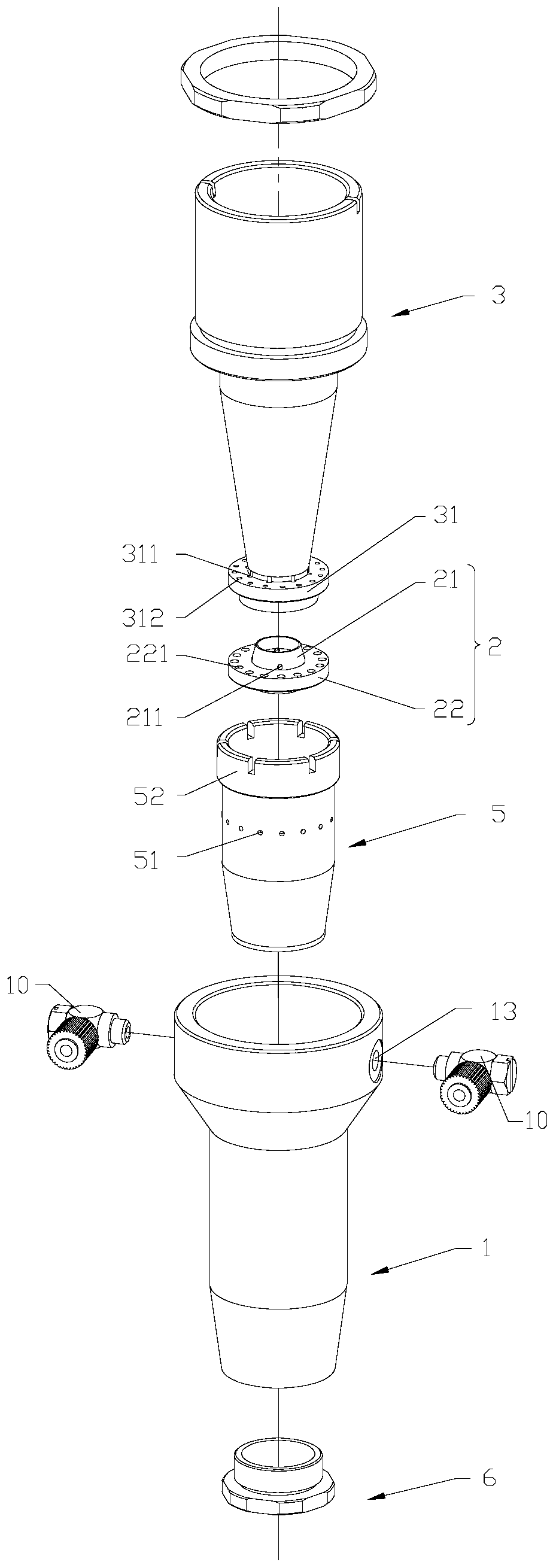

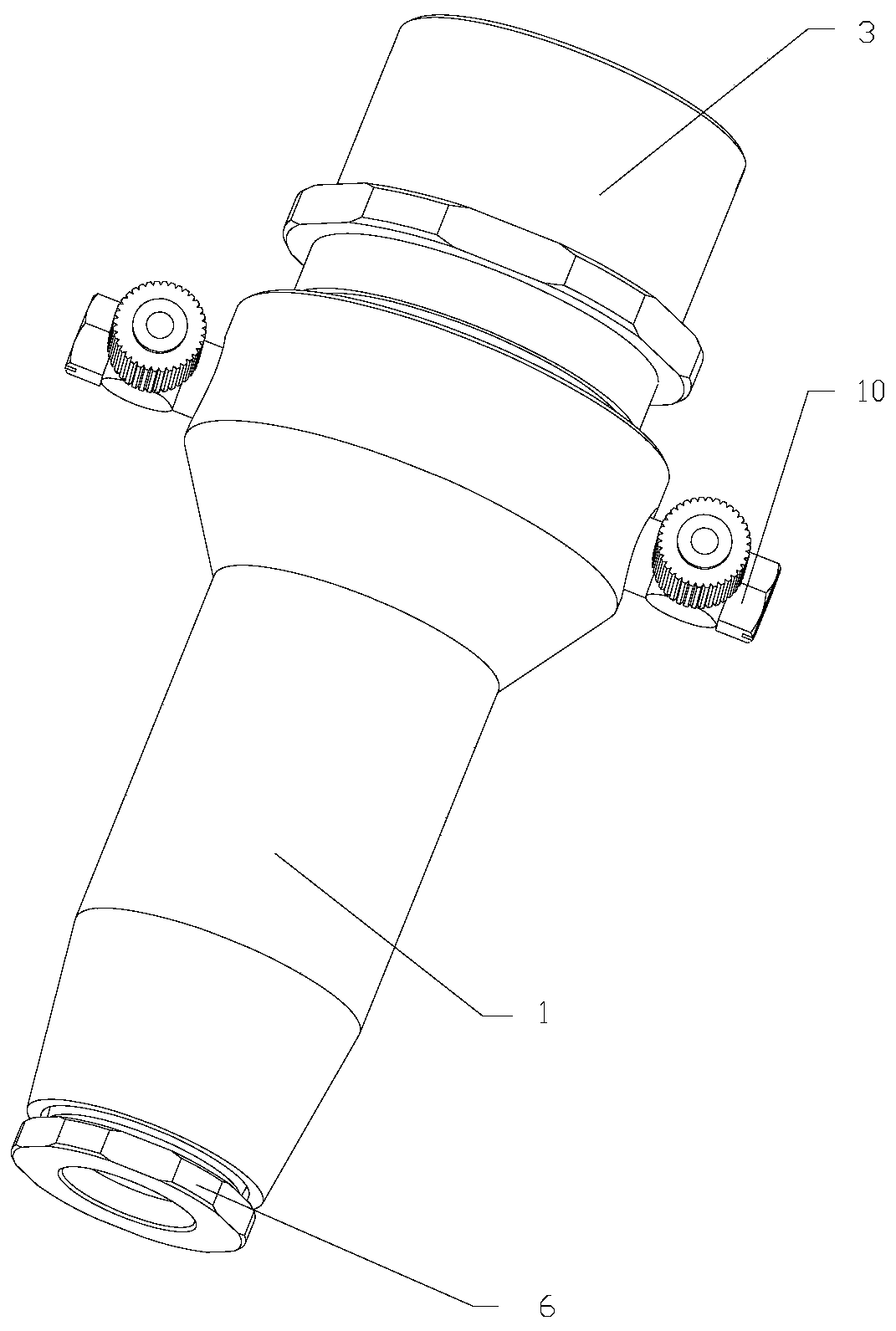

[0041] see Figure 1-4 , 6. This embodiment provides a blowing nozzle for laser welding, the blowing nozzle is used for laser welding, including: an outer tube 1, a diverter ring 2, and an inner tube 3, wherein:

[0042] The outer pipe 1 includes an air inlet end 11 and an air outlet end 12. The wall of the outer pipe 1 is provided with an air inlet hole 13, and the air inlet hole 13 is connected with an air inlet nozzle 10, and the air inlet nozzle 10 has a function of adjusting gas pressure;

[0043] The splitter ring 2 is placed coaxially in the outer tube 1 and below the air inlet 13. The splitter ring 2 includes a first annular portion 21 and a second annular portion 22 that are coaxially arranged and have unequal outer diameters. The second annular portion The outer wall of 22 is sealed with the inner wall of the outer tube 1, and the second annular part 22 is provided with a first through hole 221 communicating with the outer tube 1;

[0044] The inner pipe 3 is used to ...

Embodiment 2

[0050] On the basis of Embodiment 1, the blowing nozzle also includes a middle pipe 5 and an air curtain ring 6, the middle pipe 5 is placed under the outer pipe 1 and is located under the air inlet 13 and the outer wall is sealed with the inner wall of the outer pipe 1, and the inner pipe 3 Extending into the middle pipe 5 and abutting against the second annular portion 22, the outer wall of the inner pipe 3 and the inner wall of the middle pipe 5 form a second space 7 communicating with the air inlet 13, and the middle pipe 5 is located above the first annular flange 31 The wall of the pipe is provided with a fifth through hole 51, the splitter ring 2 is placed in the middle pipe 5, the second annular portion 22 and the first annular flange 31 are fitted and sealed with the inner wall of the middle pipe 5, and the air curtain ring 6 is set At the gas outlet 12 and sealed with the end of the middle pipe 5, the outer wall of the air curtain ring 6 is provided with a second annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com