Automatic device capable of achieving anti-corrosion paint spraying work of vertical framework in transformer substation

A technology of automatic devices and substations, applied in the direction of spraying devices, etc., can solve problems such as poor economic benefits, incomplete anti-corrosion painting, etc., to achieve the effect of ensuring the quality of the paint surface, prolonging the service life and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

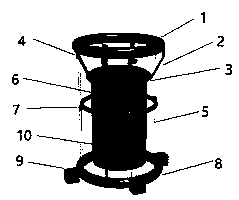

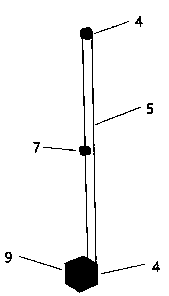

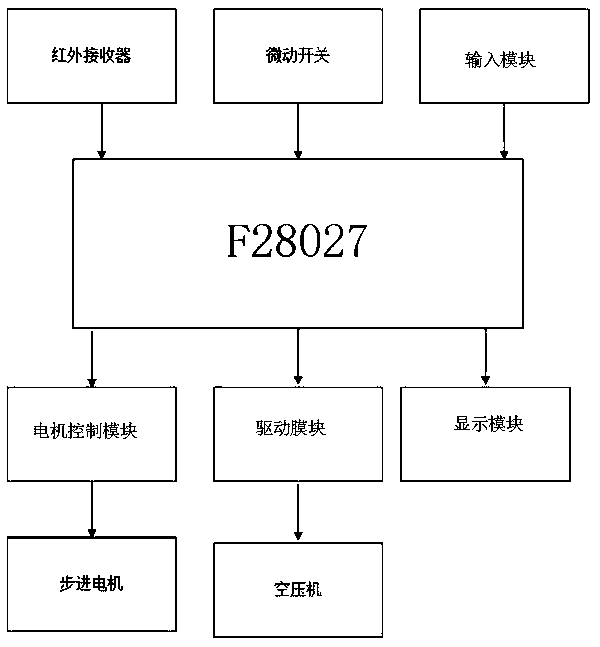

[0028] The automatic device for anti-corrosion painting of the vertical frame in this embodiment includes a suspension ring 1, a suspension ring support rod 2, a hoop 3, a pulley 4, a steel wire rope 5, an annular adjustable painting head 7, a control ring 8, a stepping motor 9, and a paint pipeline 10 .

[0029] When doing painting work:

[0030] The hoop 3 is locked onto the vertical frame 6 that needs to be painted. Fix the lifting ring support rod (2) on the hoop through bolts, and then fix the lifting ring 1 on the upper part of the lifting ring support rod 2 with bolts. The steel wire rope 5 that is fixed with annular adjustable paint spraying head 7 passes through the pulley 4 of suspension ring 1 and control ring 8 respectively, adjusts the length of wire rope according to the length of framework. After installation, it should be confirmed that the steel wire rope is parallel to the vertical frame 6 to ensure that the paint is evenly sprayed.

[0031] The up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com