Transverse cutting device of seed potato preparation dicer

A potato and dicing machine technology, which is applied in the directions of rhizome seed cutting machine, seed and rhizome treatment, application, etc., can solve the problems of lax disinfection, lack of mechanized equipment for potato seed potatoes, low efficiency, etc., to reduce labor costs, The effect of improving the cutting efficiency and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

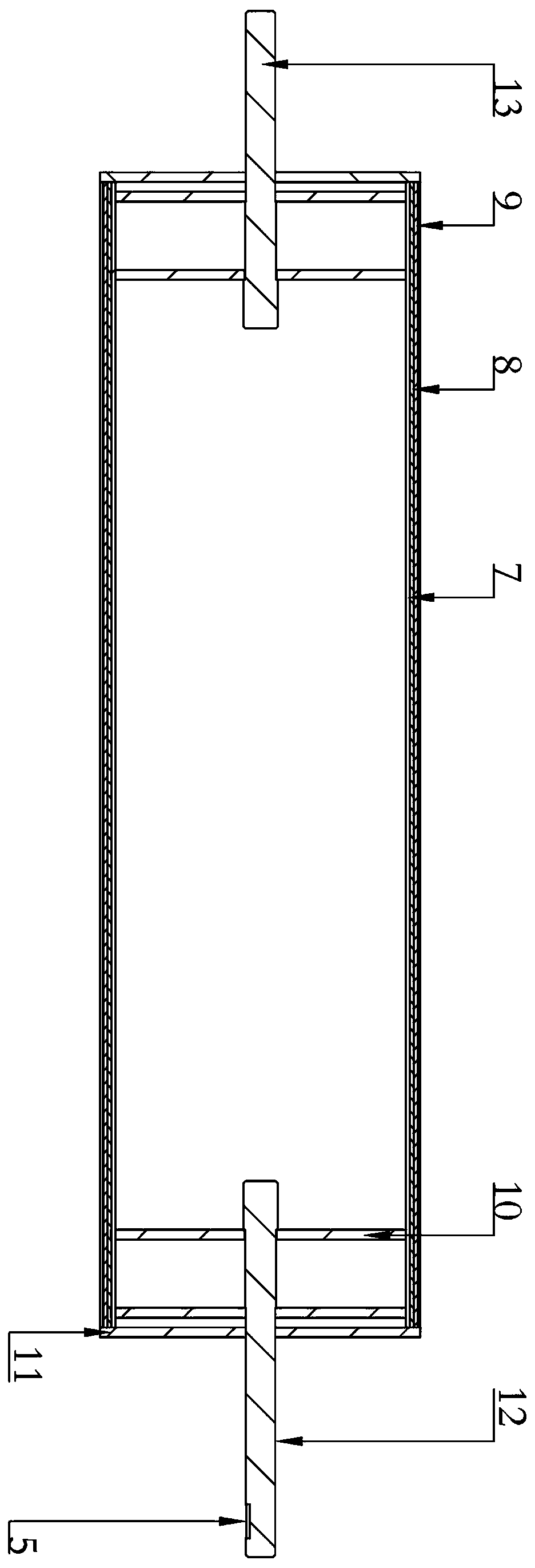

[0016] 1. Bearing seat adjustment bolt 2, sprocket 3, spacer sleeve 4, vertical seat bearing 5, common flat key 6, set screw 7, round tube 8, foam layer 9, cast rubber layer 10, reinforced circular plate 11 , outer baffle 12, left drive shaft head 13, right shaft head 14, side comb teeth 15, middle comb teeth 16, support shaft 17, comb adjustment rod 18, connecting plate 19, left pressure plate 20, locking eccentric handle 21. Fixed plate 22, connecting square plate 23, reinforcing plate 24, left main plate 25, ear plate I 26, pin shaft 27, seat plate 28, ear plate II 29, nut 30, lower reinforcing plate 31, blade.

[0017] In the present invention, "V" represents the conveying direction V of seed potatoes.

[0018] exist Figure 1~7 In the shown embodiment, the upper and lower rubber stick assemblies perpendicular to the conveying direction of potato seeds, arranged parallel to each other and arranged symmetrically are separated by a certain distance, and are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com