A Downhole Reverse Hydraulic Plugging Removal Method

A hydraulic and plug-removing technology, which is applied in earthwork drilling, wellbore/well components, and production fluids, etc., can solve problems such as poor reservoir permeability, blockage, and inability to completely return and discharge pollutants from the reservoir, and achieve blockage Thorough flowback, great economic value, promotion of erosion and dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

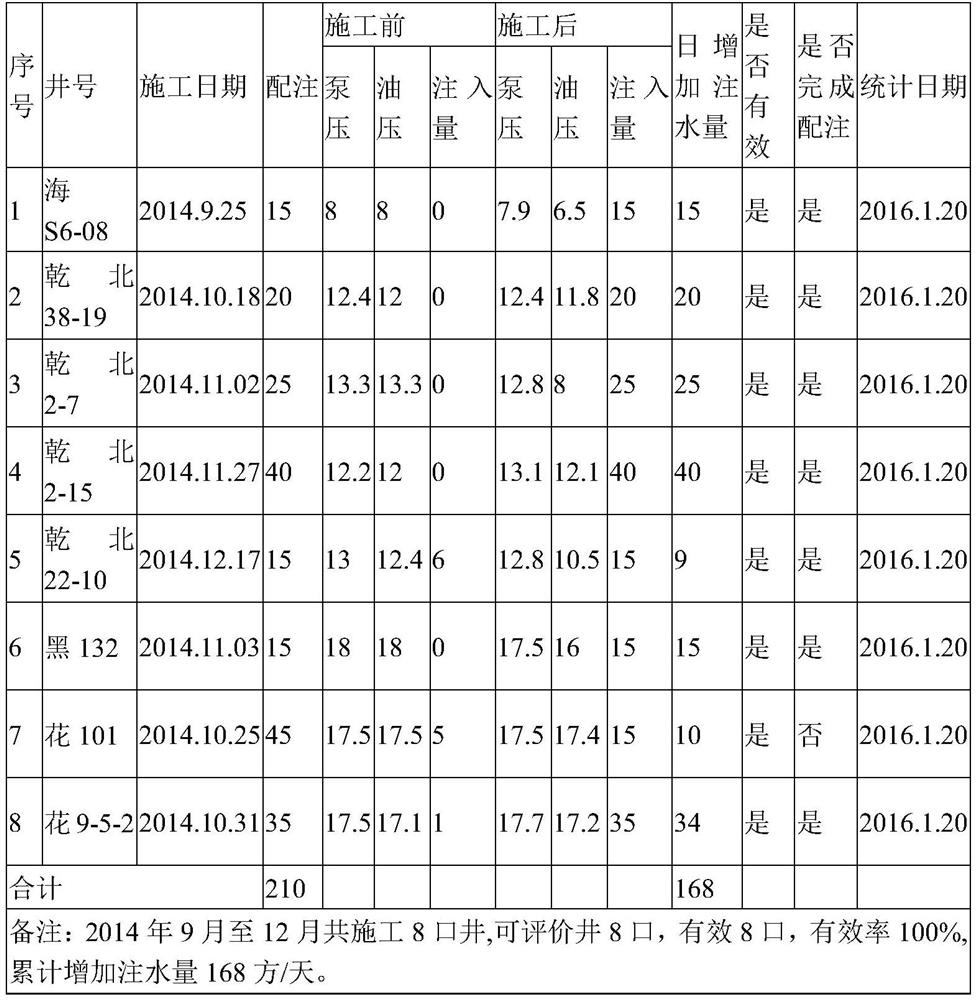

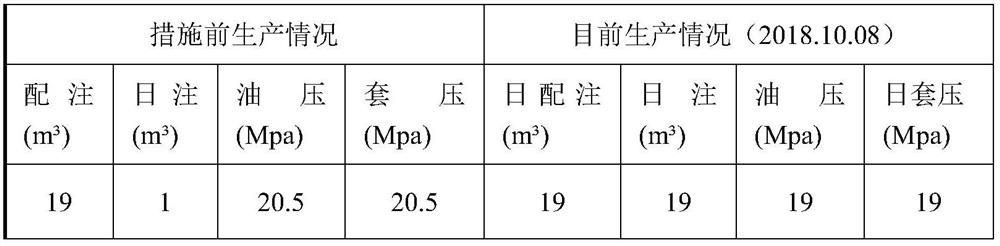

Examples

Embodiment 1

[0042] A downhole reverse hydraulic plugging removal method, comprising the following steps:

[0043] A. Acidification construction:

[0044] 1) Prepare acidified construction liquid;

[0045] 2) Squeeze injection of the prepared acidizing construction fluid into the treated target well;

[0046] 3) Shut down the target well to carry out acidizing reaction after the injection injection is completed;

[0047] B. Construction preparation for reverse hydraulic plugging removal:

[0048] 1) Connect the reverse hydraulic plugging removal device at the wellhead of the target well. The reverse hydraulic plugging removal device includes a power system, a control and monitoring system, a servo system, a manifold system, and a generator; the reverse hydraulic plugging removal device is connected to the target well After testing the instruments and meters with the field power supply, adjust the control mode of the control and monitoring system to the manual debugging mode, and put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com