Method and equipment for peeling layered material and screening and separating two-dimensional nanosheets

A technology of two-dimensional nano and layered materials, which is applied in the fields of nanotechnology, nanocarbon, and nanotechnology for materials and surface science, and can solve the problem of small size, difficulty in shearing force, and difficulty in securing two-dimensional nanosheets. and other problems, to achieve the effect of narrow size range and improved peeling yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

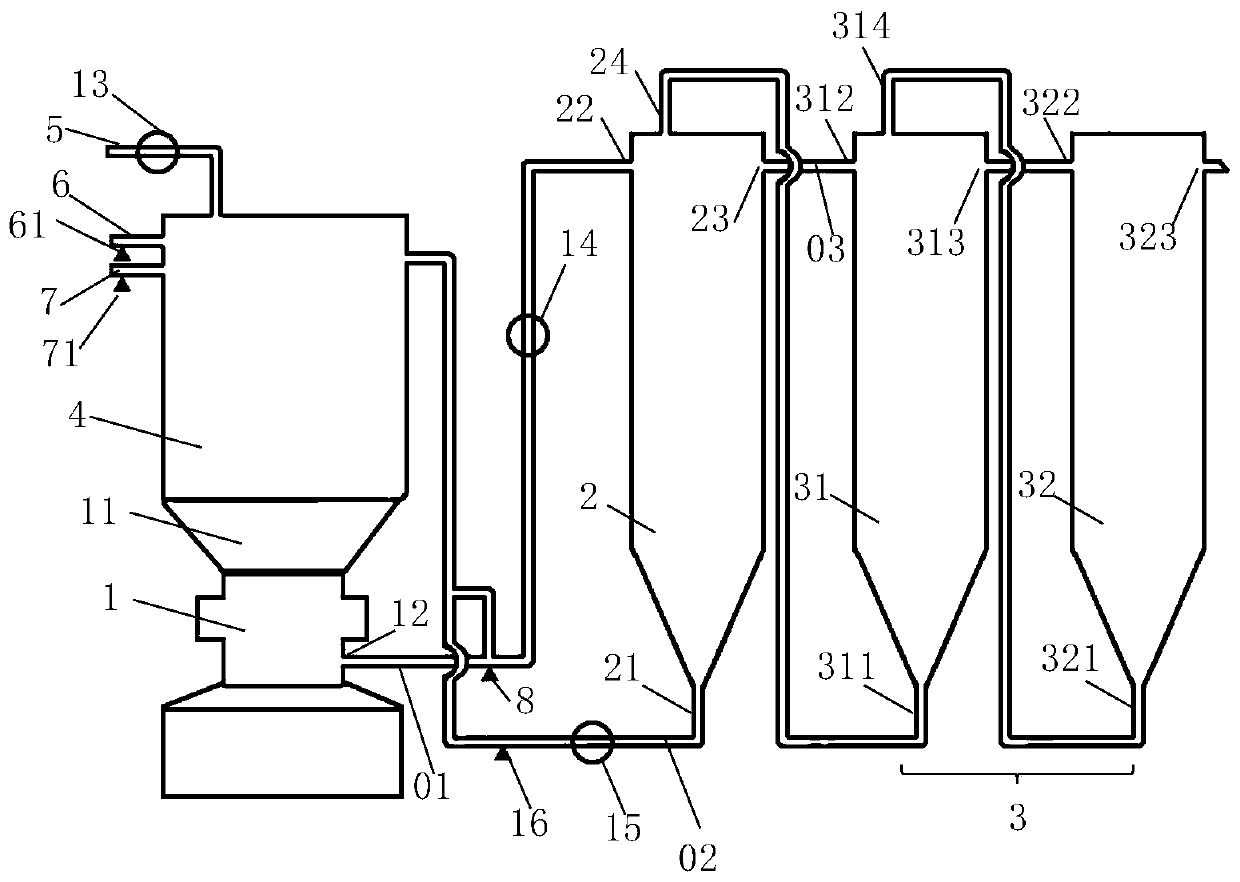

[0049] A device for exfoliating layered materials and size-screening to separate two-dimensional nanosheets, such as figure 1 As shown, it includes an emulsification disperser 1, a first-stage separator 2 (horizontal centrifuge is selected) and a cascaded separator 3 for size screening connected in series with the first-stage separator 2, and the cascaded separator 3 Including the second-stage separator 31 (selecting a horizontal centrifuge) and the third-stage separator 32 (selecting a horizontal centrifuge) connected in series; the outlet 12 of the emulsifying disperser 1 passes through the first pipeline 01 and the first The feed port 22 of the stage separator 2 is connected; the solid phase discharge port 21 of the first stage separator is connected with the feed port 11 of the emulsification disperser through the second pipeline 02 or with the storage material arranged at the feed port 11 The tank 4 is connected (the discharge port 12 of the present embodiment is connecte...

Embodiment 2

[0054] Turn on the emulsification disperser 1, the first stage separator 2 and the second stage separator 31.

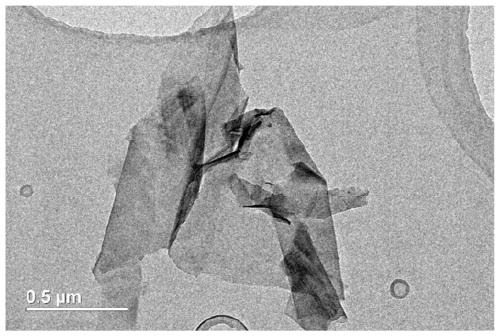

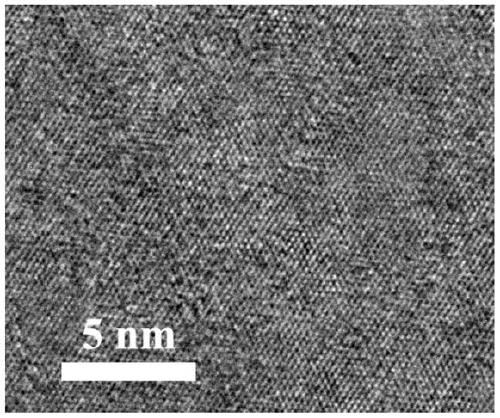

[0055] Mix 325-mesh graphite powder with 1000L N-methylpyrrolidone (NMP) evenly (graphite concentration is 10g / L), add emulsification disperser 1 under nitrogen atmosphere (rotation speed is 6000rpm, stator-rotor gap is 0.24mm) for peeling , the stripped product enters the first stage separator 2 (rotating speed is 500rpm) and carries out solid-liquid phase separation, obtains the precipitate containing the unstripped graphite and the liquid phase part containing graphene, and the precipitate returns to the storage tank In 4, after mixing with the 1000LNMP pre-added in the storage tank 4, enter the emulsification disperser 1 and circulate continuously for 10 times to obtain a large amount of graphene dispersion. The liquid phase part containing graphene enters the second stage separator 31 (rotating speed is 3000rpm), and the second stage separator 31 obtains the ave...

Embodiment 3

[0058] On the basis of Embodiment 2, first close the first output port of the emulsification disperser 1 and the first valve 8 (flowing to the outlet of the first stage separator 2) and the second valve 16, and open the second output of the first valve 8 Port (flowing to the storage tank 4), the stripped mixed solution first enters the emulsification disperser for continuous circulation and stripping for 1h, then closes the second output port of the first valve 8, opens the first output port of the first valve 8, and strips The final product enters the first stage separator 2 for solid-liquid separation. Compared with Example 2, the product concentration obtained in Example 3 is higher. According to different layered materials to be peeled off, its concentration can be increased by about 10 to 50 times, that is, the peeling yield is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com