Novel rubber inverting device for tire cord calendaring machine

A tire cord and calender technology is applied in the field of material recovery in the calendering process in tire production, which can solve problems such as affecting product quality, wasting energy, and doping products with cooked rubber particles, so as to avoid inconsistent product thickness, improve product quality, and improve product quality. The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The present invention will be described in further detail below in conjunction with the accompanying drawings.

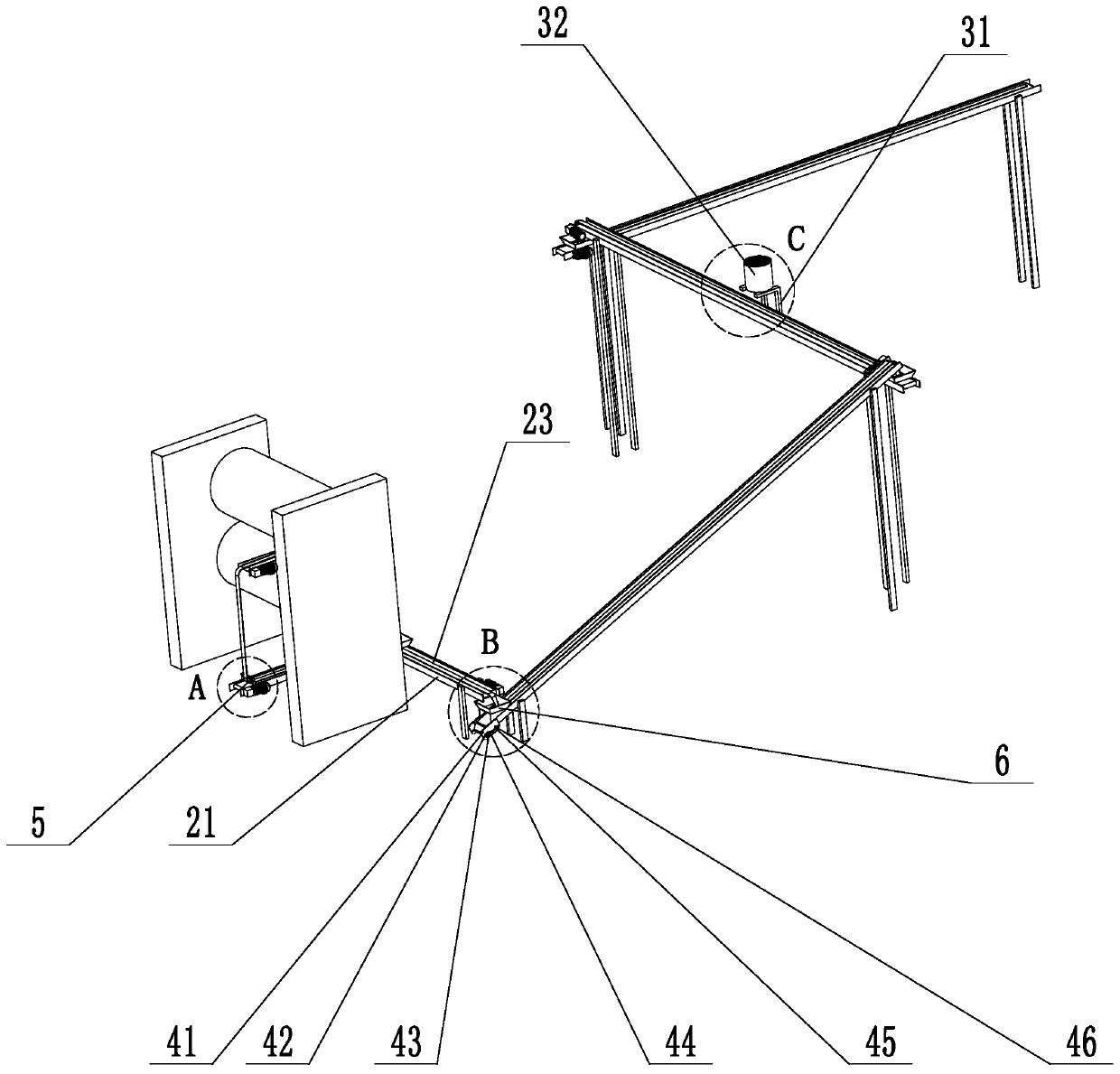

[0049] refer to figure 1 and Figure 6 , is a new type of tire cord calender anti-adhesive device disclosed by the present invention, which includes a transport part composed of a plurality of conveyors and a scraping part for collecting edge glue from the calender rollers.

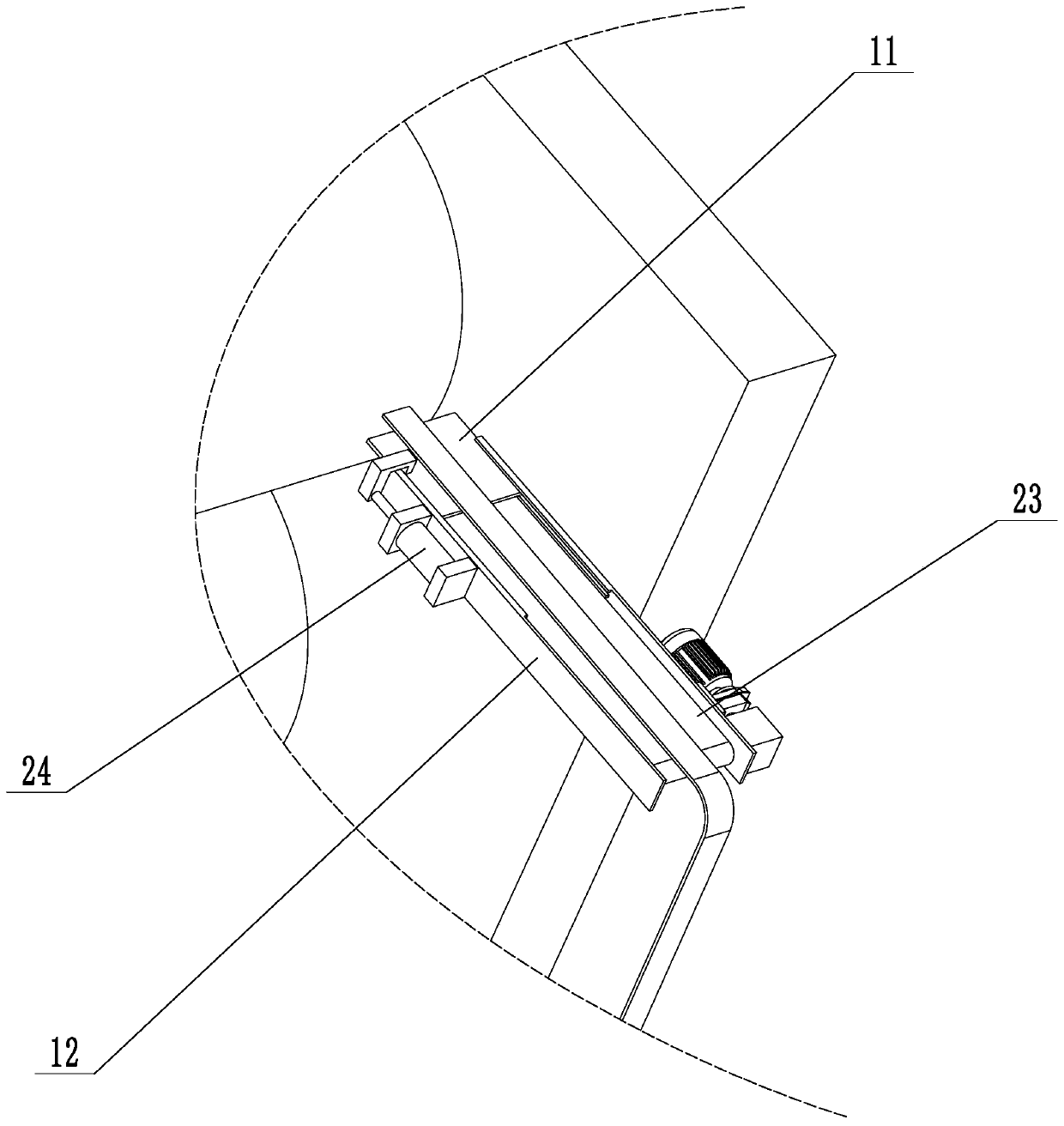

[0050] Transporter is made up of two parts of transport groove 21 and belt transport structure. Belt transport mechanism is made up of drive roller 22, conveyer belt 23 and power unit etc. Wherein the two ends of transmission roller 22 are connected with the bearings on the adjacent transportation trough 21 or are directly inserted in the hole on the transportation trough 21, and the two ends of conveyor belt 23 are respectively connected with the transmission roller 22 of transportation trough 21 two ends, and middle part rides on On the remaining driving roller 22. The power device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com