Infiltration device for composite sleeper preparation

A composite sleeper and pre-impregnation technology, applied in the direction of tracks, roads, ballast layers, etc., can solve problems such as poor fiber and resin infiltration, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Fiber pretreatment: 1) immerse the glass fiber in alkali solution with a pH value of 14 for 3 hours; 2) wash and dry, immerse in 2wt% chitosan aqueous solution for 1 hour, wash and dry to obtain the modified fiber.

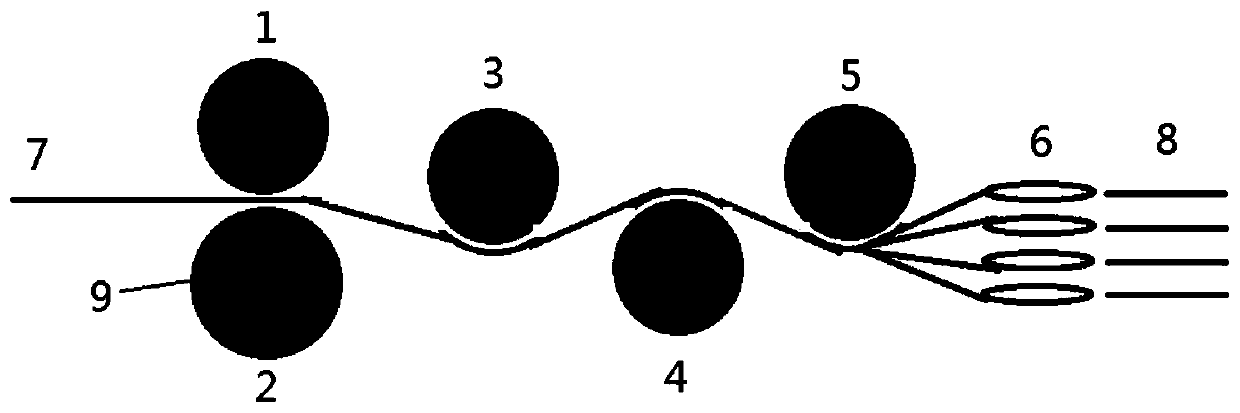

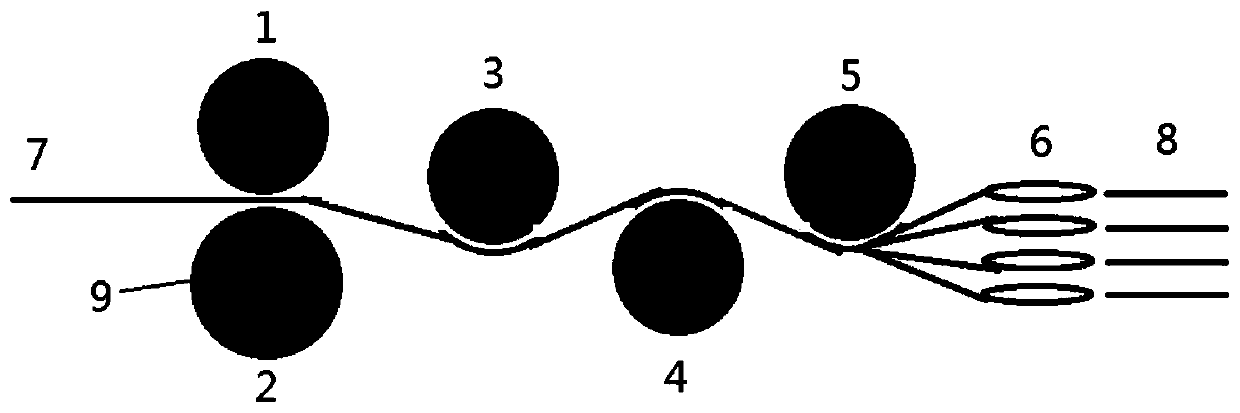

[0027] After spraying, the fiber passes through the gate composed of the primary high-frequency vibration roller and the fixed roller with rubber outer layer, and extrudes and pre-impregnates the fiber after spraying the resin; the pre-impregnated fiber continues to pass through the secondary high-frequency vibration roller The fibers are infiltrated; the fibers impregnated by the secondary high-frequency vibration roller pass through a group of preformed plates with oblong cross-section and tapered ends to form a pre-impregnated fiber composite material with uniform distribution of fibers up and down.

[0028] The diameter of the primary vibration roller is 100mm, the vibration frequency is 10,000 times / min, and the amplitude is 1mm; the diameter of the sec...

Embodiment 2

[0030] After spraying, the fibers pass through the gate formed by the primary high-frequency vibration roller and the fixed roller with rubber outer layer, and the fibers after spraying resin are extruded and pre-impregnated; the pre-impregnated fibers pass through the secondary high-frequency vibration roller to continue The fibers are infiltrated; the fibers impregnated by the secondary high-frequency vibration roller pass through a group of preformed plates with oblong cross-section and tapered ends to form a pre-impregnated fiber composite material with uniform distribution of fibers up and down.

[0031] The diameter of the primary vibration roller is 100mm, the vibration frequency is 12000 times / min, and the amplitude is 0.5mm; the diameter of the secondary vibration roller is 100mm, and three secondary vibration rollers are used, the vibration frequency is 15000 times / min, and the amplitude is 0.3mm.

[0032] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com