Hot rolling descaling pump speed increase box online monitoring diagnostic method

A diagnostic method and technology of a speed-increasing box, which are applied in length measuring devices, metal rolling, metal rolling, etc., can solve the problems of large vibration influence, difficulty in accurately evaluating the running state of descaling pump equipment, fault diagnosis, poor analysis effectiveness, etc. , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

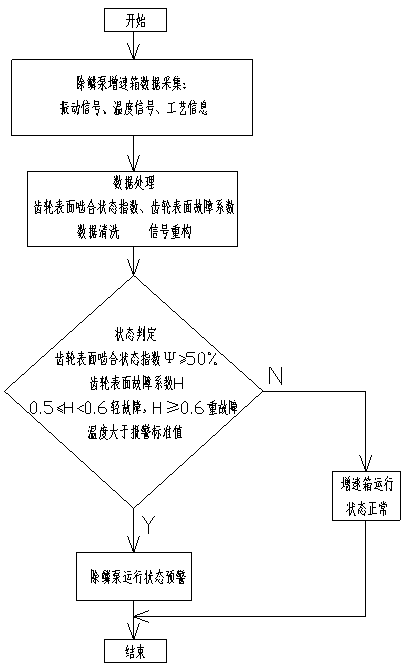

[0026] Example figure 1 As shown, the on-line monitoring and diagnosis method of the hot-rolled descaling pump gearbox of the present invention comprises the following steps:

[0027] Step 1. Install a vibration sensor and a temperature sensor for monitoring the vibration signal and temperature signal of the bearing on the bearing seat in the speed increaser box of the descaling pump, and collect the signals of the vibration sensor and temperature sensor and the spraying process signal of the descaling pump;

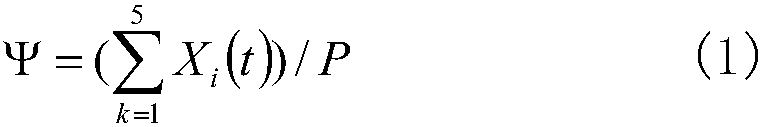

[0028] Step 2. To the original vibration signal Y of the gearbox collected by the vibration sensor i Through vibration spectrum analysis and FFT transformation, the total vibration value P and the vibration amplitude components at one, two, three, four, and five times the meshing frequencies of the gears in the gearbox are obtained respectively. x i (t), where i takes 1, 2, 3, 4 and 5, then the gear surface meshing state index of the gearbox is:

[0029]

[0030] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com