Clamping device for machining PCB and equipped with flexible clamping body structure

A flexible clamping and PCB board technology, applied in the direction of circuit board tool positioning, electrical components, printed circuit manufacturing, etc., can solve the problems of PCB edge damage, PCB board falling off, poor clamping effect, etc., to ensure production quality , Guarantee stability, improve the effect of quality inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

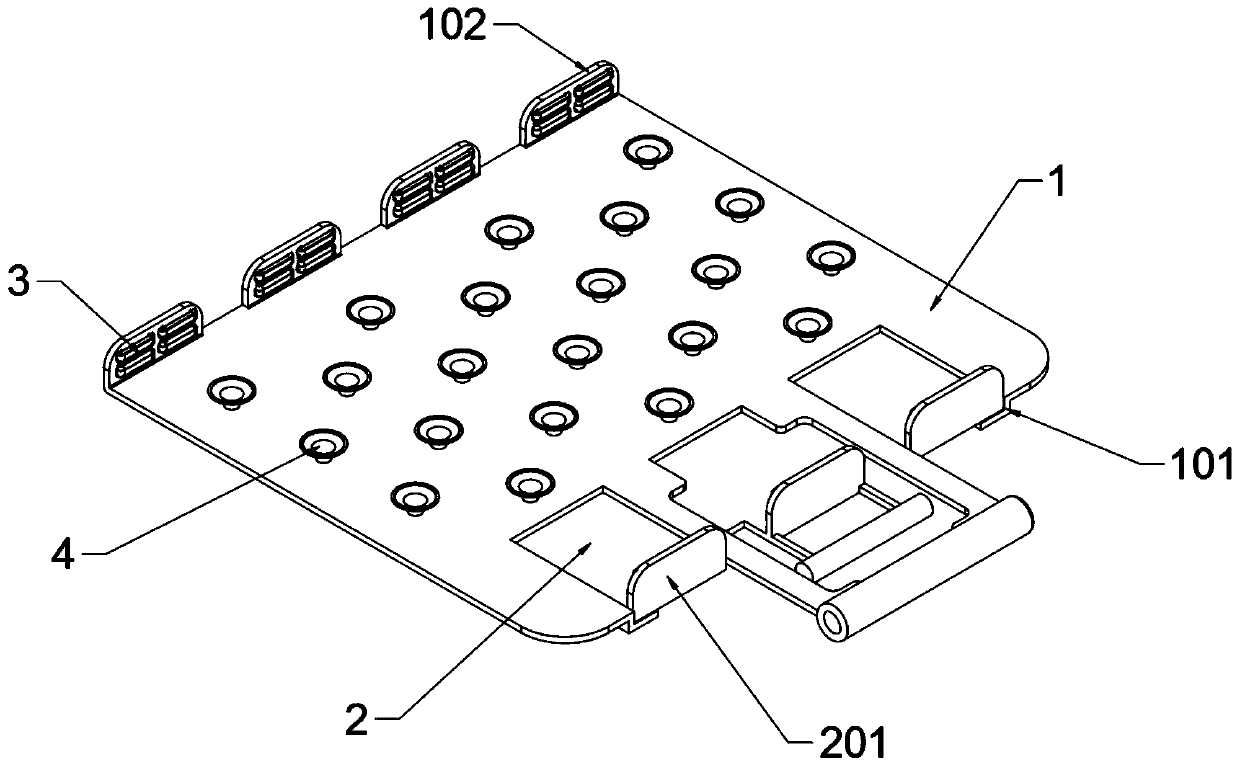

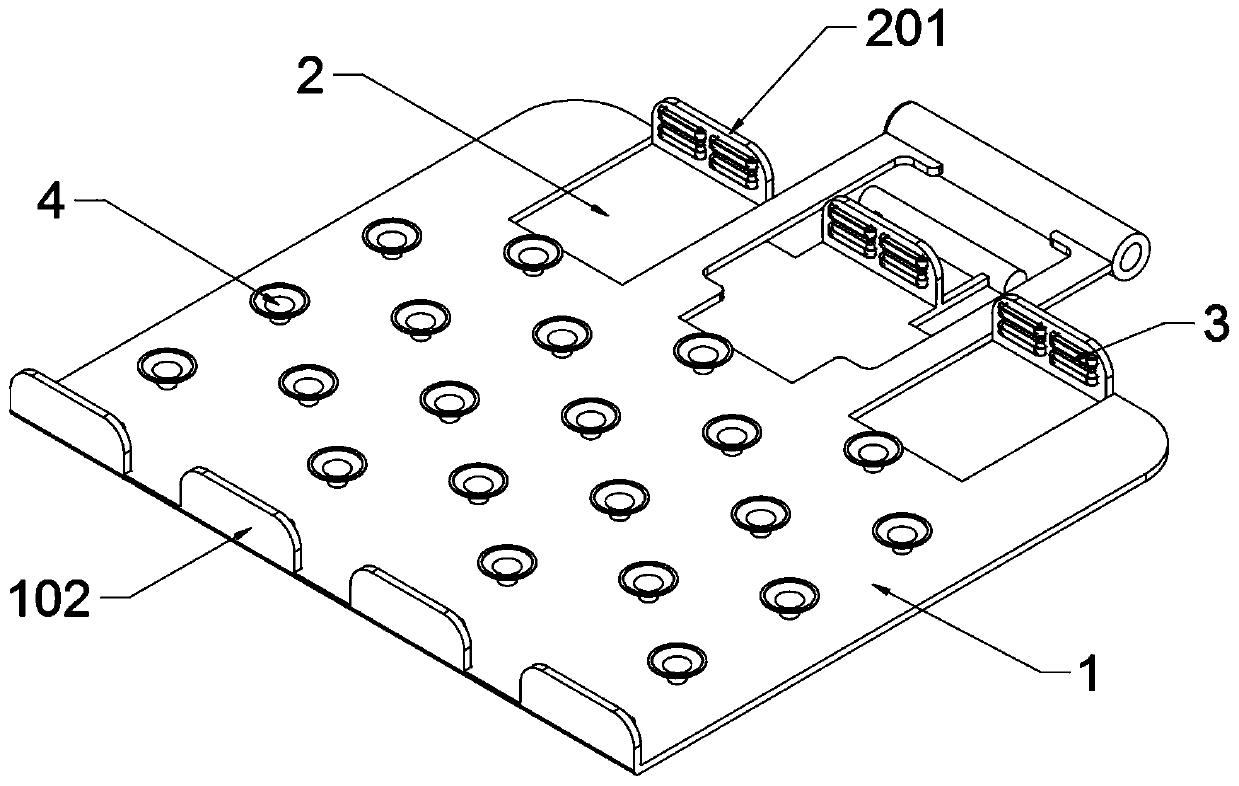

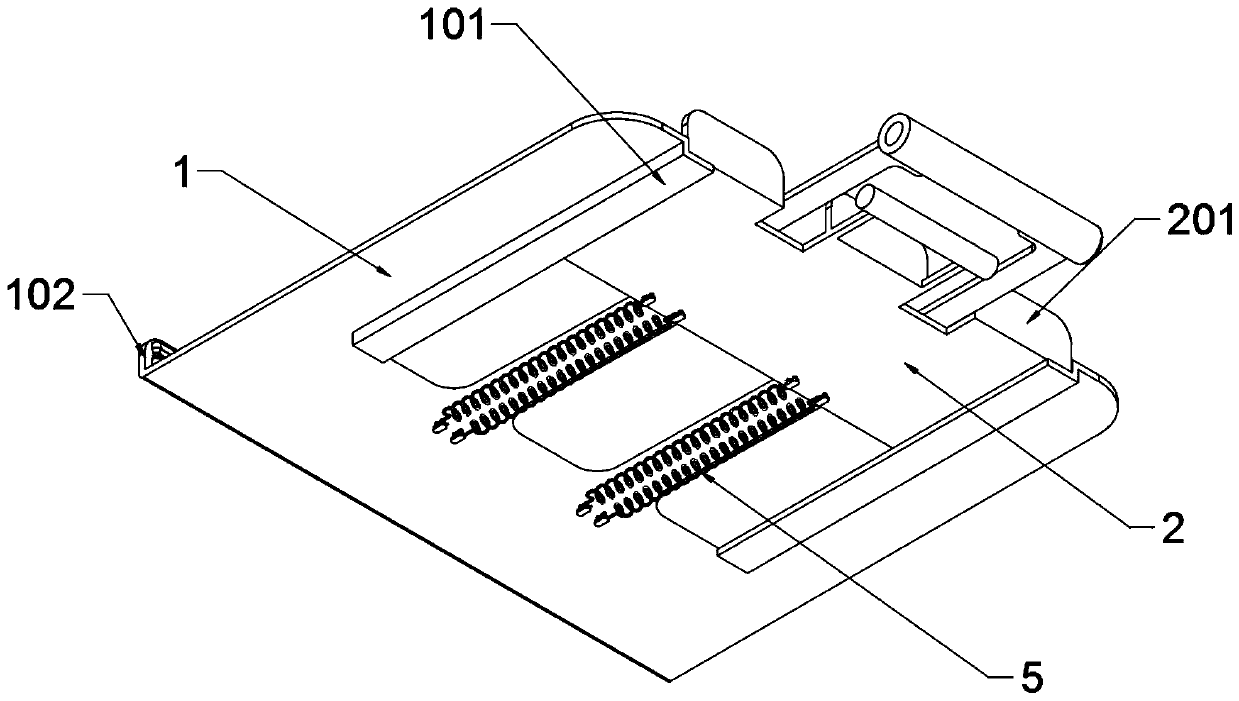

[0035] As attached figure 1 Attached Picture 10 Shown:

[0036] The present invention provides a clamping device for PCB board processing with a flexible clamping body structure. The clamping device includes a clamping plate 1, a sliding groove 101, a main clamping block 102, a movable clamping plate 2, an auxiliary clamping block 201, a latex block 3, and a flexible Suction cup 4, tension spring 5, support frame 6, support seat 7, transmission shaft 8, transmission belt 9, non-slip convex strip 901, transmission motor 10 and control electric box 11; the clamping plate 1 is a rectangular plate structure and clamps The right end of the holding plate 1 is a handle-shaped structure; the movable splint 2 is located at the bottom of the holding plate 1, and the right end of the movable splint 2 is a handle-shaped structure, and the holding plate 1 and the movable splint 2 are made of transparent plastic; the latex The block 3 has fourteen places, and the latex block 3 is respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com