Anchor mooring equipment integrated controller and working method thereof

An integrated controller and equipment technology, applied in the direction of mechanical equipment, fluid pressure actuators, servo motor components, etc., can solve the problems that the A/B two chambers of the motor cannot be filled with oil, and the integrated controller has no standby oil replenishment device, etc. , to achieve the effect of protecting the normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

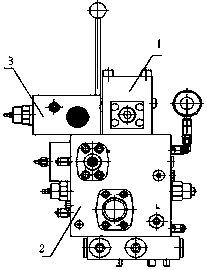

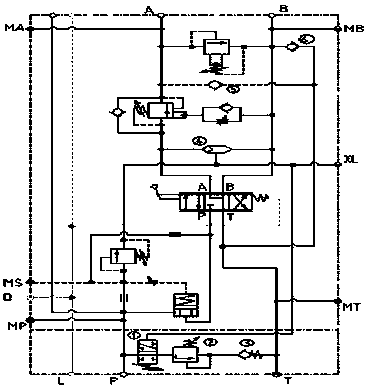

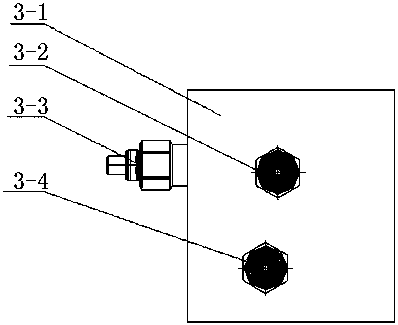

[0017] see Figure 1-Figure 3 , this embodiment provides an integrated controller for anchoring and winching equipment, including a connected manual proportional reversing valve 1 and a balance valve group 2, and also includes an oil supply valve group 3, which is fixed to the manual proportional reversing valve 1 On the balance valve group 2, the oil supply circuit from P port to T port is integrated on the oil supply valve group 3. The oil supply valve group 3 includes the oil supply valve block 3-1, the hydraulic control reversing valve 3-2, the decompression Valve 3-3 and one-way valve 3-4, the shuttle valve outlet of P port and A / B port on the balance valve group 2 are introduced into the oil supply valve group 3 through the hydraulic control reversing valve 3-2, pressure reducing valve 3-3 and check valve 3-4 get back to the T port of balance valve group 2 again.

[0018] The fuel supply valve group 3 is connected with the balance valve group 2 through bolts.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com