Control device and method for air compressor and dryer of new-energy commercial vehicle

A control method and air compressor technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve the problems of being unable to meet the variety of new energy commercial vehicles, adjusting work strategies, and less interactive information, etc., to achieve order-based The effect of rapid production, high functional safety level, and close information interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

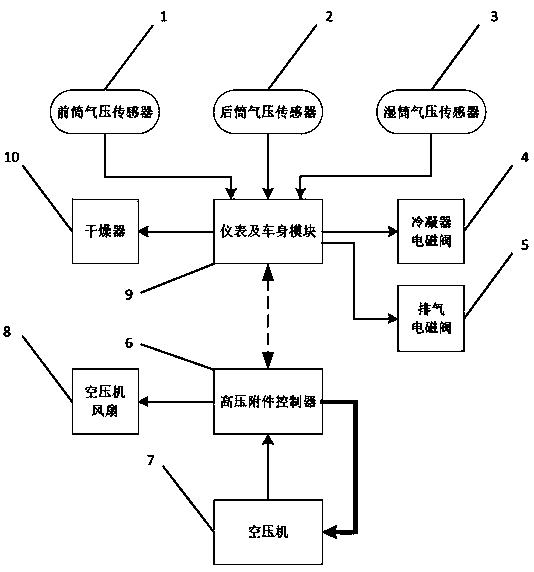

[0032] Please see attached figure 1 , a control device for a new energy commercial vehicle air compressor and dryer, including a front cylinder air pressure sensor 1, a rear cylinder air pressure sensor 2, a wet cylinder air pressure sensor 3, an exhaust solenoid valve 4, a condenser solenoid valve 5 and high-pressure accessories Controller 6; the front cylinder air pressure sensor 1 and the rear cylinder air pressure sensor 2 are respectively arranged at the air inlet and the exhaust port of the automobile air storage cylinder, and the wet cylinder air pressure sensor 3 is arranged in the automobile air storage cylinder for detecting the intake air of the automobile air storage cylinder. The air port, exhaust port and internal air pressure, the output ends of the front barrel air pressure sensor 1, the rear barrel air pressure sensor 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com