A kind of production method of drynaria extract

A technology of Rhizoma Drynariae extract and production method, applied in the field of production of Rhizoma Drynariae extract, can solve problems such as poor arsenic removal effect, and achieve the effects of high retention rate, improved removal rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take drynaria drynaria 100kg, remove impurities, crush into coarse particles, add drinking water to extract twice according to the process of 8BV, 2h; 6BV, 1.5h, filter and combine the two medicinal liquids, and concentrate under reduced pressure to a relative density of 1.02g / ml (75°C), add chitosan oligosaccharide and activated carbon to the concentrated solution for adsorption, wherein, the amount of chitosan oligosaccharide added is 0.05% of the concentrated liquid mass, the amount of activated carbon added is 0.03% of the concentrated liquid mass, and the adsorption time is 60min , the adsorption temperature is 75°C; after the adsorbed sample solution is left to stand, it is filtered through a 400-mesh sieve to remove coarse carbon particles, and then filtered with a 0.1 μm microfiltration membrane, and the filtrate is concentrated and dried to obtain Drynaria rhizome extract.

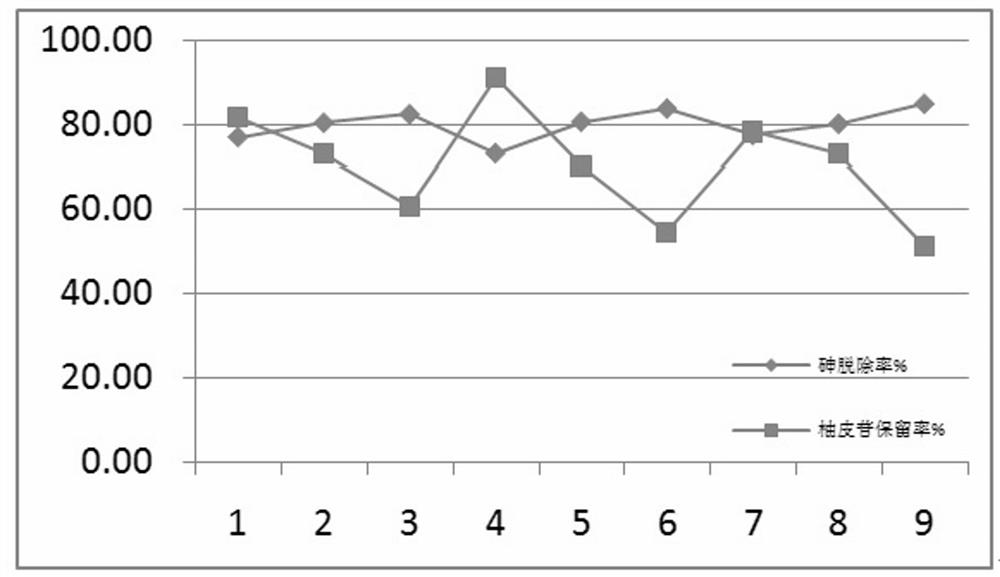

[0036] After testing, the removal rate of arsenic was 73%, and the retention rate of na...

Embodiment 2

[0038] Take drynaria drynaria 100kg, remove impurities and crush into coarse particles, add drinking water to extract twice according to the process of 10BV, 2h; ml (75°C), add chitosan oligosaccharide and activated carbon to the concentrated solution for adsorption. Among them, the amount of chitosan oligosaccharide added is 0.03% of the concentrated liquid mass, the amount of activated carbon added is 0.03% of the concentrated liquid mass, and the adsorption time is 30min. The temperature of adsorption is 50°C; after the adsorbed sample solution is left to stand, the coarse carbon particles are filtered out with a 400-mesh filter, and then filtered with a 0.1 μm microfiltration membrane, and the filtrate is concentrated and dried to obtain Drynaria drynaria extract.

[0039] After testing, the removal rate of arsenic was 77%, and the retention rate of naringin was 82%.

Embodiment 3

[0041]Take drynaria drynaria 100kg, grind it into coarse particles after removing impurities, add drinking water to extract twice according to the process of 9BV, 1.5h; g / ml (75°C), add chitosan oligosaccharide and activated carbon to the concentrated solution for adsorption, wherein, the amount of chitosan oligosaccharide added is 0.03% of the concentrated liquid mass, the amount of activated carbon added is 0.05% of the concentrated liquid mass, and the adsorption time is 60min, the adsorption temperature was 65°C; after the adsorbed sample solution was left standing, the coarse carbon particles were filtered out with a 400-mesh filter, and then filtered with a 0.1μm microfiltration membrane, and the filtrate was concentrated and dried to obtain Drynaria drynaria extract.

[0042] After testing, the removal rate of arsenic is 80%, and the retention rate of naringin is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com