Liquid injection device and method of lithium ion battery

A technology of lithium ion battery and liquid injection device, which is applied to secondary batteries, battery pack parts, circuits, etc., can solve the problems of affecting production efficiency, prolonged liquid injection time, slow liquid absorption of pole pieces, etc., so as to improve efficiency , The effect of increasing the wetting speed and reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

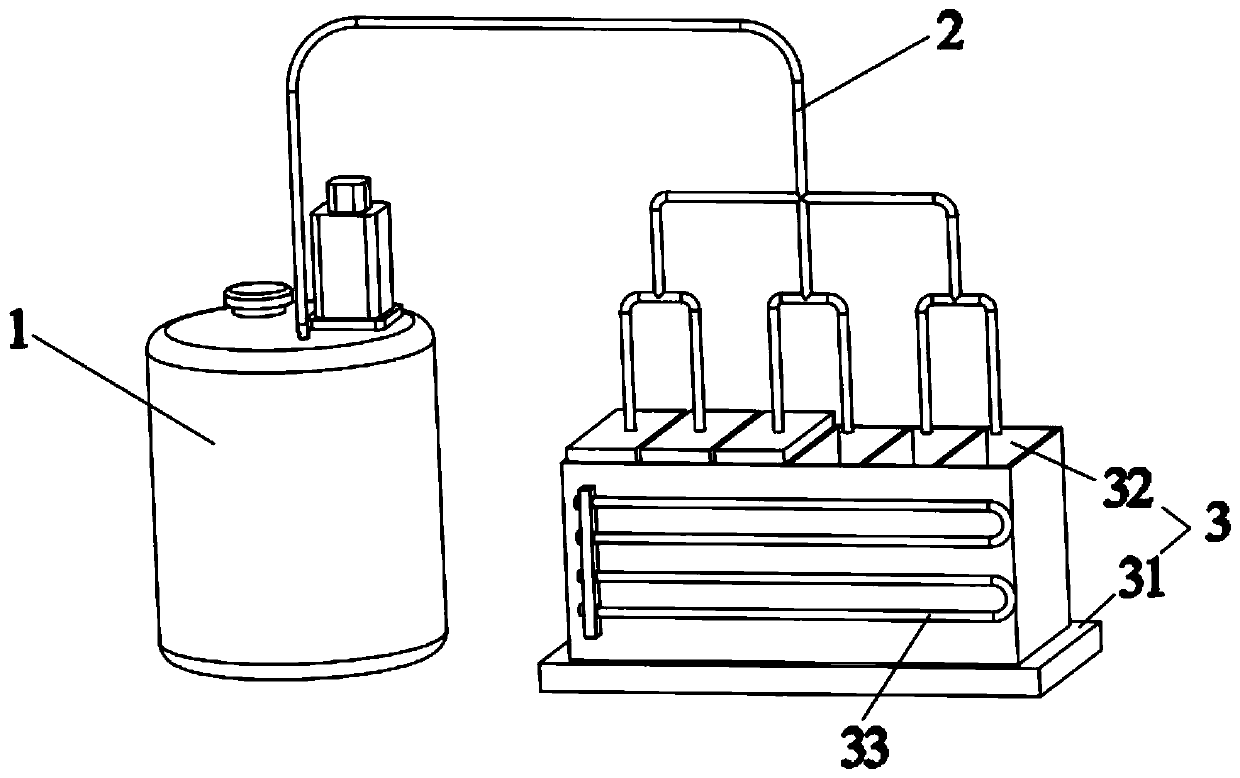

[0033] Such as Figure 1~3 As shown, a liquid injection device for a lithium ion battery includes a liquid storage tank 1, a liquid injection pipe 2 and a clamp 3, the liquid storage tank 1 communicates with the liquid injection pipe 2, the liquid injection pipe 2 is arranged above the clamp 3, and the liquid storage tank 1 includes an outer tank wall layer 11 and an inner tank wall layer 12, a closed first cavity is formed between the outer tank wall layer 11 and the inner tank wall layer 12, and a first heating element 13 is provided in the first cavity.

[0034] In the actual operation of the present invention, the liquid storage tank 1 is heated by energizing the first heating element 13, the temperature of the liquid storage tank 1 rises, and the heat heats the electrolyte in the liquid storage tank 1 through the action of heat conduction, and electrolysis As the temperature of the liquid increases, its viscosity will also decrease, and its fluidity will become better, so...

Embodiment 2

[0041] Such as Figure 1~3 Shown, a kind of lithium ion battery filling method comprises the following steps:

[0042] Step 1) heating the battery cell, heating the battery cell to 10°C, and then loading the battery cell into the holding tank 32 of the fixture 3;

[0043] Step 2) Heating the electrolyte, using the first heating element 13 in the liquid storage tank 1 to heat the electrolyte stored in the liquid storage tank 1 by 10°C, and maintaining a constant temperature;

[0044] Step 3) Heat the liquid injection pipe 2, use the second heating element 23 in the liquid injection pipe 2 to heat the liquid injection pipe 2 by 10°C, and keep the temperature constant;

[0045] Step 4) Inject liquid, press down the liquid injection nozzle of the liquid injection pipe 2 to seal the liquid injection nozzle and the liquid injection port of the battery cell, and then inject the electrolyte in the liquid storage tank 1 into the battery core;

[0046] Above step 1), step 2) and step ...

Embodiment 3

[0048] A liquid injection method for a lithium ion battery, comprising the following steps:

[0049] Step 1) heating the electric core, heating the electric core to 30°C, and then loading the electric core into the holding tank 32 of the fixture 3;

[0050] Step 2) heating the electrolyte, using the first heating element 13 in the liquid storage tank 1 to heat the electrolyte stored in the liquid storage tank 1 to 30°C, and keeping the constant temperature;

[0051] Step 3) Heat the liquid injection pipe 2, use the second heating element 23 in the liquid injection pipe 2 to heat the liquid injection pipe 2 to 30°C, and keep the temperature constant;

[0052] Step 4) Inject liquid, press down the liquid injection nozzle of the liquid injection pipe 2 to seal the liquid injection nozzle and the liquid injection port of the battery cell, and then inject the electrolyte in the liquid storage tank 1 into the battery core;

[0053] Above step 1), step 2) and step 3) are carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com